- Home

- >

News

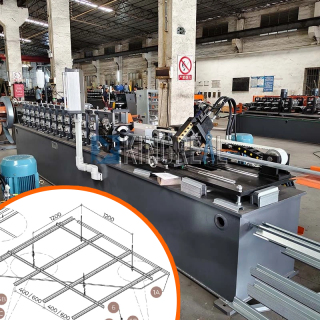

In the production and manufacturing system of the suspended ceiling system, the main channel making machine, as a key device in the false ceiling channel machine, provides important basic profile support for the construction of the ceiling system. U channel roll forming machines typically use aluminum, GI steel or PPGI with a thickness of 0.4-1.2mm as metal raw materials. Under the coordinated operation of a series of precision components such as decoiler, roll forming machine, cutting station and output table, u channels that meet the installation requirements of ceiling systems are ultimately produced. This u channel produced by the main channel making machine is often used in practical applications in combination with the furring channels and wall angles produced by the omega channel machine and l-shaped profile making machine, jointly applied in the installation of suspended ceiling systems, providing customers with a complete and efficient suspended ceiling system solution to meet the suspended ceiling construction needs in different building scenarios.