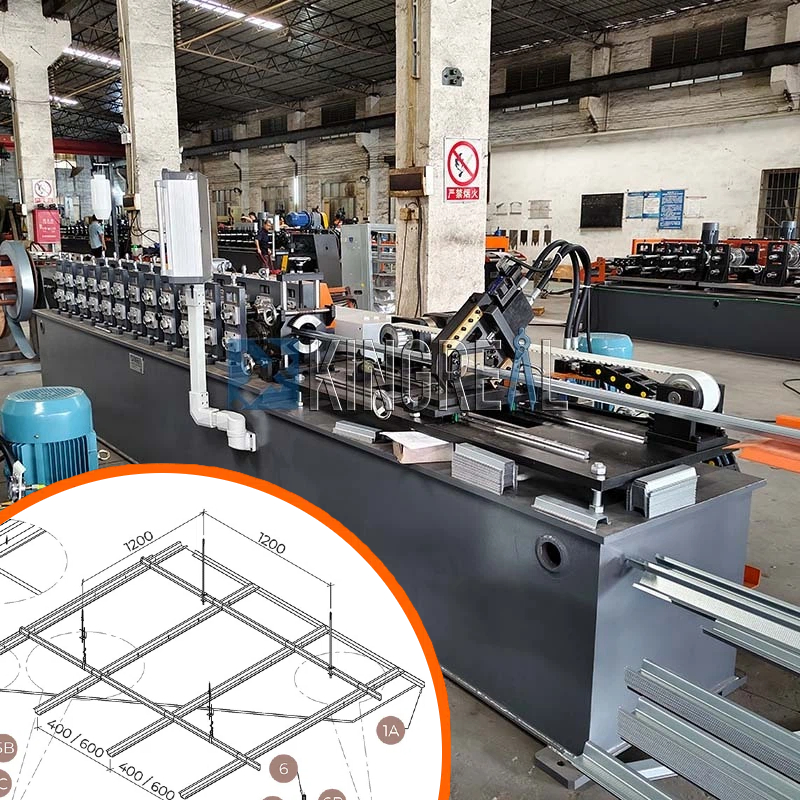

Main Channel Making Machine for Suspended Ceiling System

2025-09-29 12:00In the production and manufacturing system of the suspended ceiling system, the main channel making machine, as a key device in the false ceiling channel machine, provides important basic profile support for the construction of the ceiling system. U channel roll forming machines typically use aluminum, GI steel or PPGI with a thickness of 0.4-1.2mm as metal raw materials. Under the coordinated operation of a series of precision components such as decoiler, roll forming machine, cutting station and output table, u channels that meet the installation requirements of ceiling systems are ultimately produced. This u channel produced by the main channel making machine is often used in practical applications in combination with the furring channels and wall angles produced by the omega channel machine and l-shaped profile making machine, jointly applied in the installation of suspended ceiling systems, providing customers with a complete and efficient suspended ceiling system solution to meet the suspended ceiling construction needs in different building scenarios.

KINGREAL u channel roll forming machine features remarkable characteristics such as high-speed operation and precise production. Meanwhile, to better meet the diverse and special production demands of customers, KINGREAL engineers can also, based on the specific requirements of customers, equip the main channel making machine with optional devices such as engraving rollers, inkjet device, protective shield, and automatic packaging machine.

With the continuous development of the social economy, various new construction projects and renovation projects of old buildings are constantly increasing. The demand for suspended ceiling systems, as an important component of interior decoration and functional realization in buildings, continues to grow. As the core equipment capable of manufacturing the u channel, an important component in the suspended ceiling installation system, the main channel making machine naturally faces an increasing market demand along with the growing demand for suspended ceiling systems. The quality and performance of the u channel roll forming machine directly affect the production efficiency and quality of the u channel, and further influence the installation quality and overall performance of the suspended ceiling system.

Key Role of Main Channel Making Machine in Suspended Ceiling System

(1) Provide u channels of different specifications

KINGREAL u channel roll forming machine can fully meet the diverse specification requirements of u channel for suspended ceiling systems in different building scenarios. According to the specific requirements of suspended ceiling systems in different scenarios of customers, it can produce u channels of different sizes. Among them, common u channel sizes include 38x10x3000mm, 38x12x3000mm, etc. These sizes of u channels have been widely used in various conventional suspended ceiling projects.

KINGREAL main channel making machine can produce u channels that fully meet customer requirements in terms of size. Whether it is special width, height or length requirements, they can all be achieved through customized u channel roll forming machine.

(2) Provide large-scale u channels

The maximum production speed of KINGREAL main channel making machine can reach 120m/min. During continuous operation, it can quickly process a large number of u channels, significantly improving the production efficiency for customers.

This efficient production capacity enables customers to obtain an adequate supply of profiles when facing large-scale ceiling installation projects, without worrying about delays in the construction period due to insufficient profile quantities.

(3) Provide high-precision u channels

KINGREAL u channel roll forming machine is equipped with high-hardness rollers and high-quality material blades. During the forming process, high-hardness rollers can ensure that the metal raw materials maintain a stable shape during processing, avoiding profile deformation or dimensional deviation caused by insufficient roller hardness. High-quality material blades can achieve precise cutting, ensuring that the cut of u channels is smooth and free of burrs, and the cutting dimensions are accurate. Through the synergy of these high-quality components, the u channels produced by KINGREAL u channel roll forming machine have a small precision error range, which can meet the high-precision profile requirements of the suspended ceiling system. Meanwhile, this main channel making machine also features stable operational performance. After setting the same production parameters, it can continuously produce highly consistent finished products, ensuring that each batch of u channels meets unified quality standards.

Installation of U Channels in Suspended Ceiling Systems

The u channels produced by the u channel roll forming machine need to follow the standardized steps during the installation process of the suspended ceiling system to ensure the installation quality and stability of the suspended ceiling system. Among them, the installation of a complete suspended ceiling system requires profiles produced by main channel making machine, l-shaped profile making machine and hat channel machine. The specific installation process is as follows:

Step 1: fix the steel wire hanger. wire hangers were fixed to the top ceiling of the building using a gunpowder nailing. During the fixation process, the installation position and spacing of the steel wire hangers should be determined based on the design layout of the suspended ceiling system to ensure that the steel wire hangers can evenly bear the weight of the suspended ceiling system and provide stable support for the subsequent construction of the suspended ceiling structure.

Step 2: adjust the height of the hanger. Assemble the wire hangers with adjustable clips, and then adjust the adjustable clips according to the preset installation height of the suspended ceiling system to make the height of the wire hangers meet the installation requirements of the suspended ceiling. This step is directly related to whether the final ceiling height meets the design standards, so precise measurement and adjustment are required.

Step 3: Suspend the u channel and connect the omega channel. Combine the wire hangers with the channel brackets, and suspend the u channels through the channel brackets to ensure that the u channels remain level and accurately positioned during the suspension process. Subsequently, wire coupling clips are used to bind and connect the furring channel and the u channel, making the two closely combined to form the basic framework structure of the suspended ceiling system.

Step 4: Fix the omega channel. The hat channel is fixed to the wall of the building through screws. This step can further enhance the connection stability between the ceiling frame and the building structure, prevent the ceiling frame from shaking or shifting during use, and ensure the overall structural firmness of the suspended ceiling system.

Step 5: Install the gypsum board. Finally, fix the gypsum board to the surface of the furring channel and the wall angle profile. During the fixation process, it is necessary to ensure that the connection between the gypsum board and the profile is tight and the gaps between the gypsum boards are uniform, so as to guarantee the flatness and aesthetics of the ceiling surface, and at the same time enhance the sound insulation, heat insulation and other functions of the suspended ceiling system.