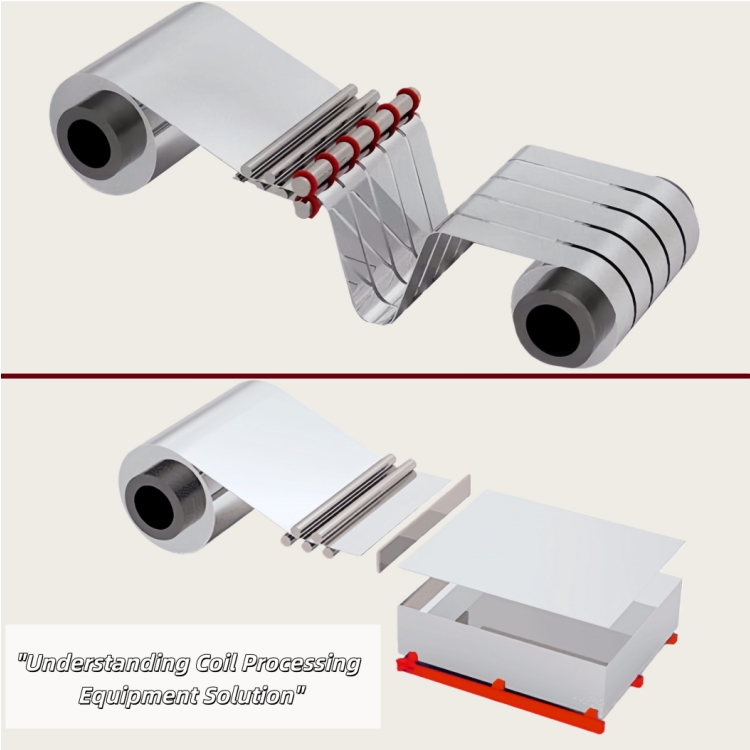

Understanding Coil Processing Equipment Solution

2025-09-19 12:00Coil processing line plays a vital role in modern manufacturing. Whether in the automotive, home appliance, or building materials industries, coil processing equipment solutions provide strong support for improving production efficiency and product quality. Leveraging its extensive experience and technology, KINGREAL offers customers a wide range of coil processing equipment solutions, primarily for processing steel, stainless steel, copper, silicon steel, aluminum, PPGI, and other materials.

Description of Coil Processing Equipment Solution

Coil processing equipment solutions cover a wide range of areas, with steel coil slitting lines and metal cut to length lines being the most representative types of coil processing lines. They specialize in slitting metal coils, helping to produce various specifications to meet customer needs.

Steel Coil Slitting Line

Steel coil slitting lines cut metal sheets or coils longitudinally into narrow strips of varying specifications. This allows customers to customize their products to meet specific size, thickness, and width requirements.

The main components of a steel coil slitting line include: decoiler, metal slitter, slitting recoiler, slitting tension unit, and separator unit.

Metal Cut to Length Line

Metal cut to length lines perform horizontal cutting of metal coils, first decoiling and flattening the large coils, then precisely cutting them to produce metal sheets of the desired dimensions.

The main components of a metal cut to length line include: Decoiler and Loading Car, Coil Straightener, Metal Leveler, Coil Feeder, Sheet Shearing Unit, Conveyor Unit, and Stacking Unit.

Various Coil Processing Equipment Solutions

KINGREAL designs a variety of coil processing line solutions based on customer drawings and actual production requirements, taking into account the policies, environment, and weather conditions of the customer's country and region to meet diverse customer needs.

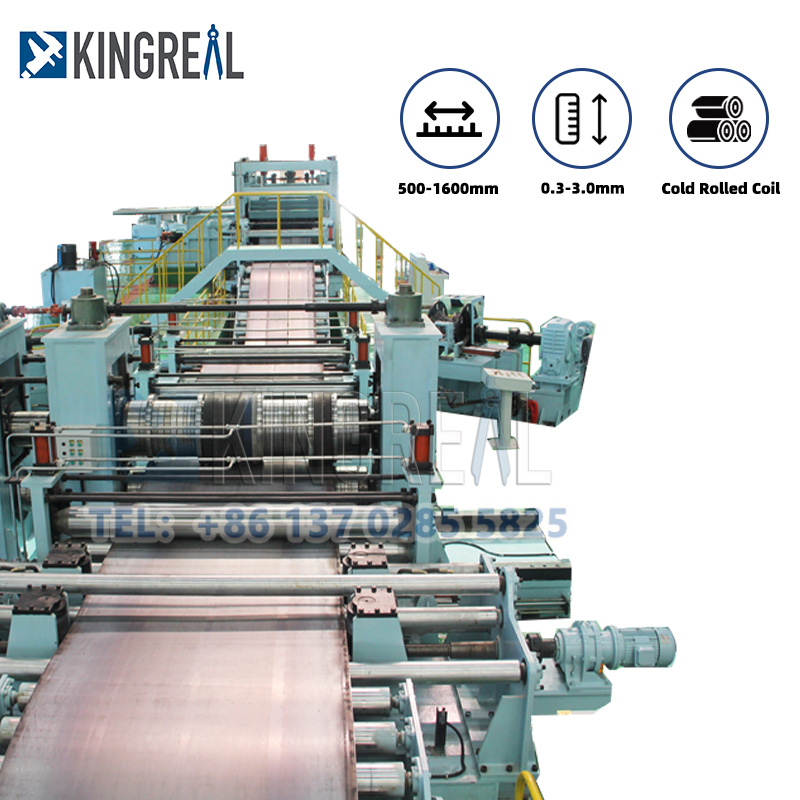

Steel Coil Slitting Line Solutions

Steel coil slitting line solutions can be customized to suit different metal materials and thicknesses. For example:

-Based on Metal Material:

KINGREAL offers a variety of metal coil slitting machines, including silicon steel slitting machines, stainless steel slitting machines, cold rolled slitting machines, hot rolled slitting machines, aluminum slitting machines, and galvanized steel slitting machines. For customers processing a single material, KINGREAL has designed specialized metal coil slitting machines. For those processing multiple materials simultaneously, KINGREAL offers metal coil slitting machines that can handle different materials.

-Based on material thickness:

Steel coil slitting lines are further categorized as heavy gauge steel coil slitting lines (6-16mm), medium gauge slitting machines (3-6mm), and light gauge slitting machines (0.2-3mm). This categorization allows customers to select the most appropriate steel coil slitting line based on their processing needs, avoiding material waste.

-For customized requirements:

KINGREAL also offers high speed coil slitting lines with a maximum production speed of 230m/min, significantly improving production efficiency. Furthermore, the dual slitter head coil slitting machine uses a worm gear to adjust the blade shaft spacing, enabling high-precision control of the gap between the upper and lower shafts. The belt tension steel slitting machine is particularly suitable for steel strips or aluminum sheets with high surface requirements, ensuring scratch-free slitting during the slitting process.

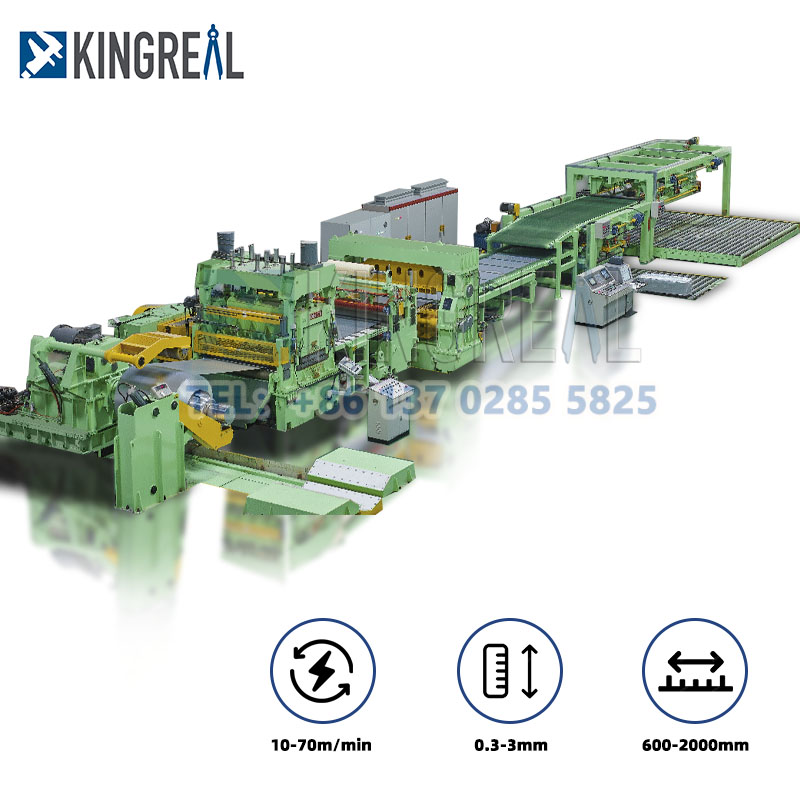

Metal Cut to Length Line Solutions

KINGREAL also offers a variety of solutions for metal cut to length lines:

-Based on material thickness:

Metal cut to length lines can be divided into heavy duty cut to length lines (6-25mm), medium duty cut to length lines (0.3-6mm), and light duty cut to length lines (0.2-3mm), meeting customer needs for materials of varying thicknesses.

-Based on shearing method:

Metal cut to length lines include fly shearing cut to length line, rotary shearing cut to length line, swing shearing cut to length line, and fixed shearing cut to length line, allowing customers to select the appropriate metal cut to length line based on their production needs.

-Based on customized requirements:

To improve plate flatness, KINGREAL designs metal cut to length lines equipped with double levelers, ensuring that the coil undergoes a double leveling process before cutting. Metal cut to length lines can also be equipped with a laminating device to reduce scratches on the plate surface. By coating the metal coil with a layer of film before cutting, the blades prevent scratches on the surface.

The Importance of Coil Processing Lines

In today's world of progress and technological advancement, coil processing lines not only improve production efficiency but also enhance production quality for manufacturers. Through automated and intelligent solutions, coil processing equipment solution effectively reduces material loss and improves overall production efficiency. Especially for large-scale manufacturers, utilizing efficient coil processing equipment solutions can significantly increase production capacity and meet rapidly changing market demands.

Understanding coil processing equipment solutions is crucial for modern manufacturing. KINGREAL offers a wide range of coil processing line, including specialized equipment such as steel coil slitting lines and metal cut to length lines, as well as customized solutions tailored to customer needs. These coil processing line and coil processing line solution play a significant role in improving production efficiency and ensuring product quality. In the future, with the continuous advancement of technology, the intelligence and automation of coil processing line will continue to improve, opening up new prospects for the development of the manufacturing industry.