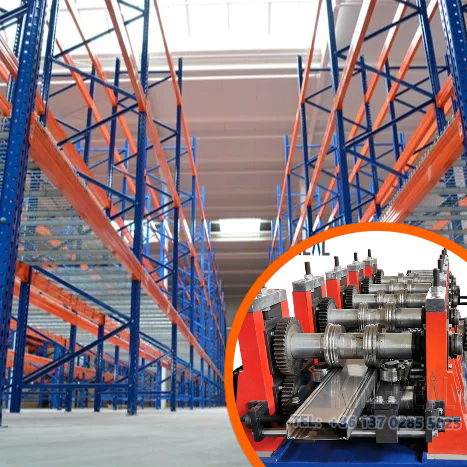

Understanding pallet racking system: What is box beam making machine?

2025-09-17 12:00Pallet racking systems play a vital role in modern logistics and warehousing. Whether in supermarkets, warehouses, or homes, shelving is the optimal solution for expanding storage space. A key component of these pallet racking systems is the box beam making machine, also known as a rack box beaming machine. This box beam making machine is specifically designed to manufacture high-quality box beams, forming a core component of efficient warehousing solutions.

KINGREAL designed the rack box beaming machine based on market demand and years of R&D and production experience. With the increasing demand for warehousing, traditional shelving solutions are no longer able to meet modern requirements. The emergence of the box beam making machine not only improves production efficiency but also allows for custom adjustments to each box beam specification. This flexibility has earned it widespread market acceptance.

One of the design features of the rack box beaming machine is its ability to achieve a tolerance of less than 0.2mm on its finished products. This means that whether producing in large quantities or customizing individual pieces, the box beam making machine ensures precision and consistency for each product. Furthermore, its high production speed allows products to be quickly brought to market, meeting the diverse needs of customers.

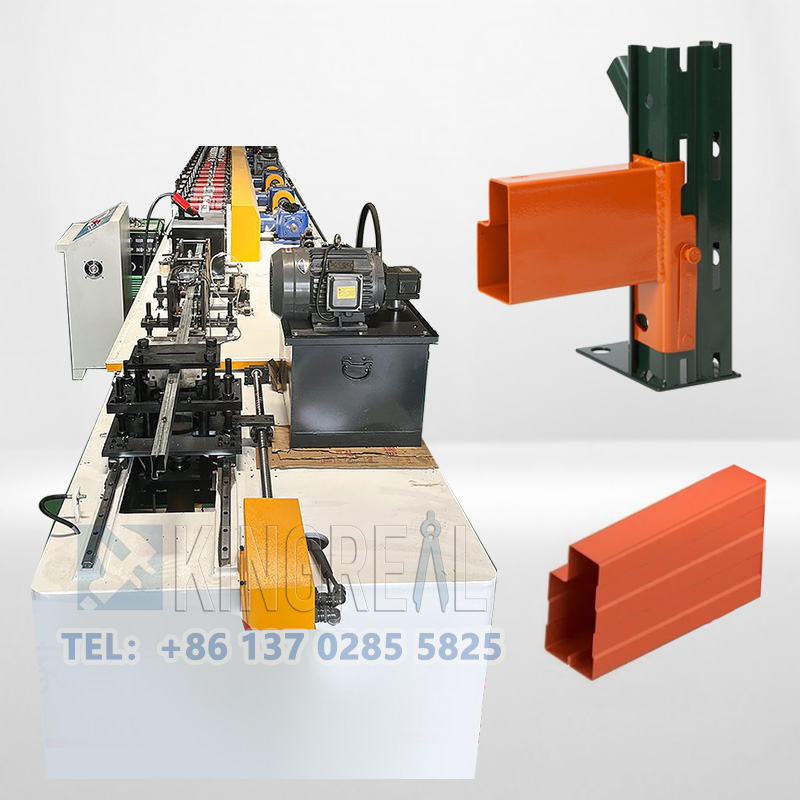

Introduction to Rack Box Beaming Machine

KINGREAL box beam making machine specializes in processing sheet metal with a thickness of 2.0mm-3.0mm. Its scientifically designed structure, simple operation, safety and reliability, stable production process, and wide product applications make it an indispensable piece of equipment in modern warehousing systems.

The rack box beaming machine's automated design significantly simplifies the operation process. The entire production process, from C-profile production to box beam locking, is automated. Specifically, the automated process includes the following steps:

All C-profile dimensions are adjusted by PLC control.

The locking process from C-profile to box beam is automated.

The C-profile is automatically transferred to the locking position via a conveyor system.

This series of automated features improves production efficiency and reduces errors caused by human operation.

Workflow of Rack Box Beaming Machine

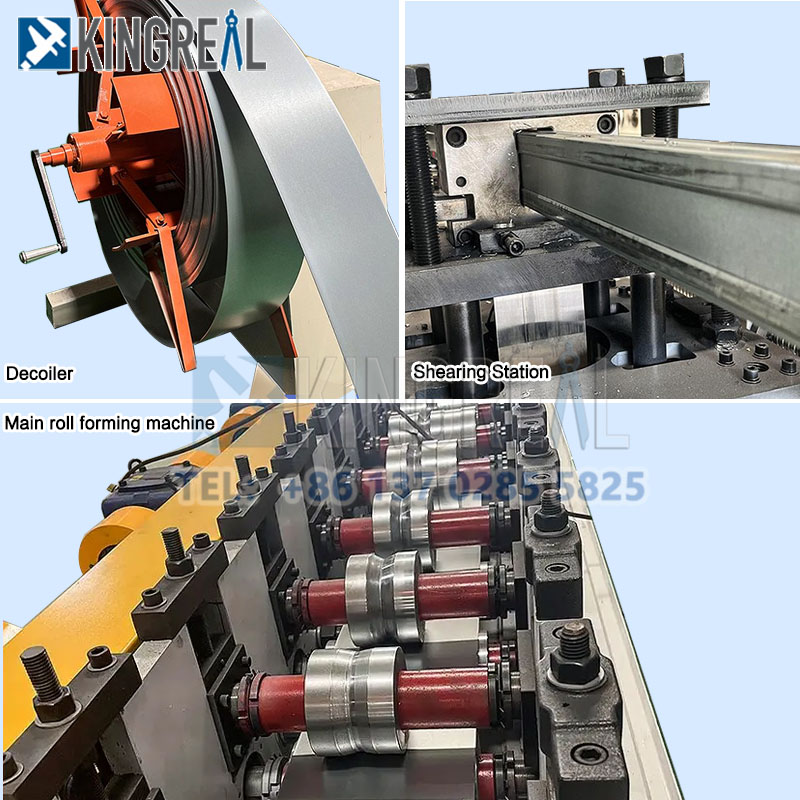

Uncoil → Continuously Cold Roll Forming → Follow Shearing → Automatic Turning → Composite Station (Seaming Machine) → Product Output.

Parameters of Rack Box Beaming Machine

| Box beam making machine | ||

| Material | GI,AI | Thickness: 2.0-3.0mm |

| Decoiler | Automatic Decoiler | Manual Decoiler |

Main body | Roller Station | (20 rows) (customized by your requirements) |

| Shaft Diameter | 80 mm solid | |

| Roller Material | Gcr12mov | |

| Frame | 500 H-steel | |

| Drive | Chain | |

| Cutter | Automatic | CR12MOV material, scratch-free and deformation-fre |

| Power Supply | Motor Power | 7.5kW |

| Hydraulic System Power | 7.5kW | |

| Voltage | 380V 50Hz 3phase | customized by your requirements |

Control System | Electrical box | Customizable (brand name) |

| Language | English (multiple languages supported) | |

| PLC | PLC for automated production of the entire machine. Batch size, length, quantity, and other parameters can be set. | |

| Forming Speed | 15-20m/min | Depending on material thickness. |

Main Components of Rack Box Beaming Machine

Part 1: Automatic Size Change and PLC Control

The box beam making machine allows users to produce box beams of any size within a certain range. The mold moves along its axis, allowing dimensions to be adjusted as needed, making production more flexible.

Part 2: Conveyor system for rack box beaming machine

The conveyor system is responsible for transporting C-beams to the locking machine. C-beams are efficiently transferred through this system, ensuring a smooth production process.

Part 3:Locking Machine for box beam making machine

The locking machine is a key component of the box beam making machine. It locks the manufactured box beams and transports them to the receiving station, completing the entire production process.

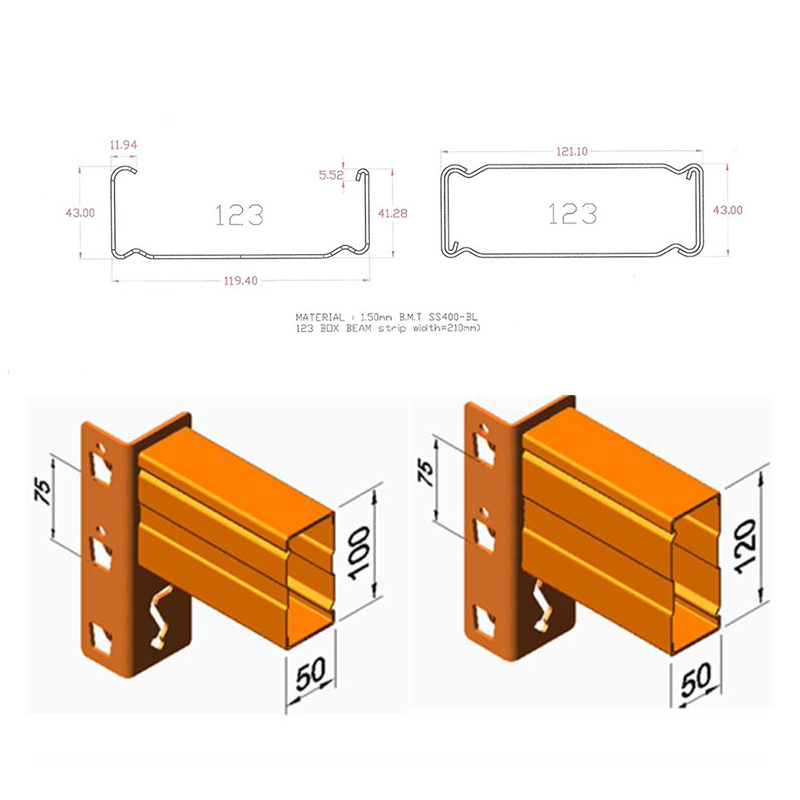

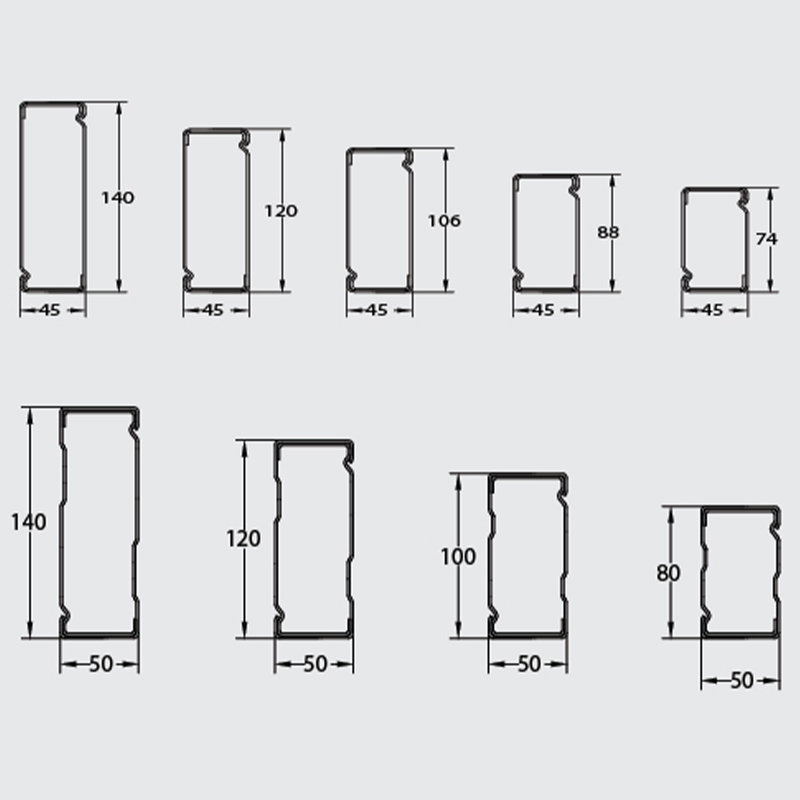

Parameters of Finished Rack Box Beaming

The box beam making machine produces box beams in a variety of sizes, including the following:

| Model TB | Height (A) | Width(B) |

| TB 80 | 80 | 50 |

| TB 100 | 100 | 50 |

| TB 120 | 120 | 50 |

| TB 130 | 130 | 50 |

Each box beam size offers excellent load-bearing capacity, suitable for a variety of storage needs.

Applications of Box Beam Making Machine

Box beams produced by the box beam making machine are sturdy horizontal support components widely used in pallet racking systems. They serve as connectors, preventing beams from sagging and ensuring racking stability and safety. Each beam is designed with a built-in mechanism that securely slots into slots on the uprights, providing additional security.

In addition, box beams are designed with load capacity and capacity in mind, adapting to different load types. Load level variations are often determined by the number and size of pallets being stored, making appropriate box beam selection crucial.