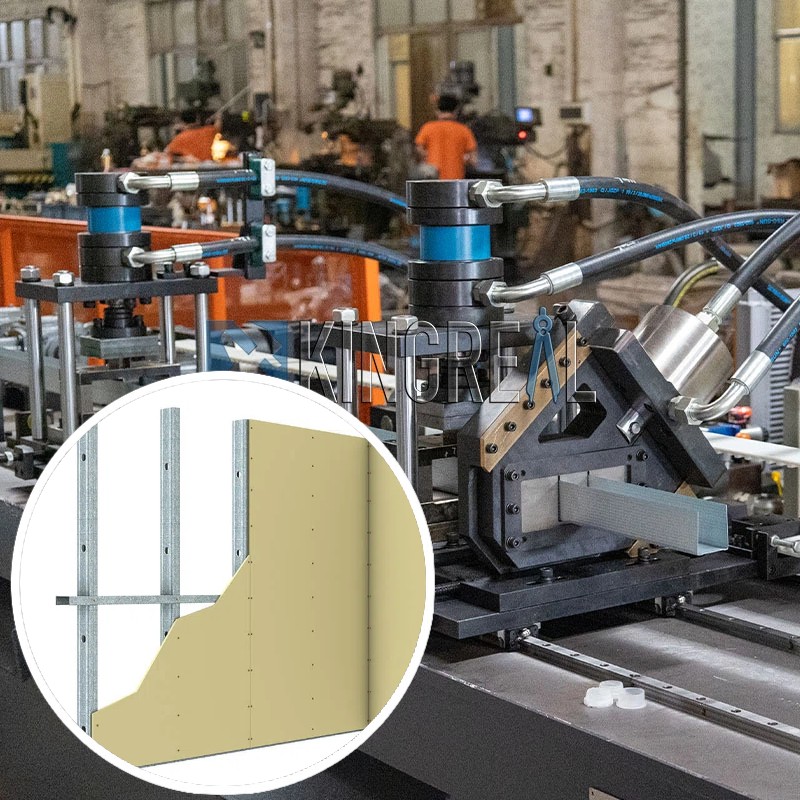

Metal stud and track machine for drywall framing system

2025-09-14 12:00Metal stud and track machine, also known as drywall profile machine, gypsum board channel machine, and drywall stud and track machine, play a vital role in the modern construction industry. This drywall profile machine not only improves construction efficiency but also ensures the quality and precision of the finished product. Using galvanized coils as raw material, the metal stud and track machine utilizes a series of precision components, including the decoiler, main roll forming machine, hydraulic fly punching and shearing system, and product table, to produce metal studs and tracks of various specifications using a cold bending process. These studs and tracks are used as metal frameworks in construction projects.

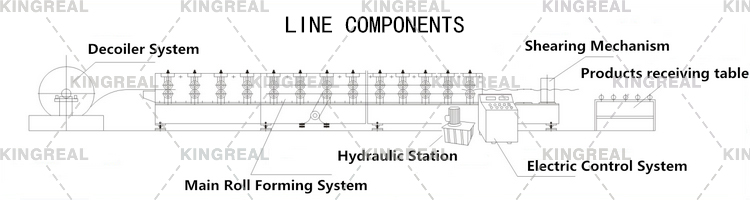

1/ Working Process of Drywall Profile Machine

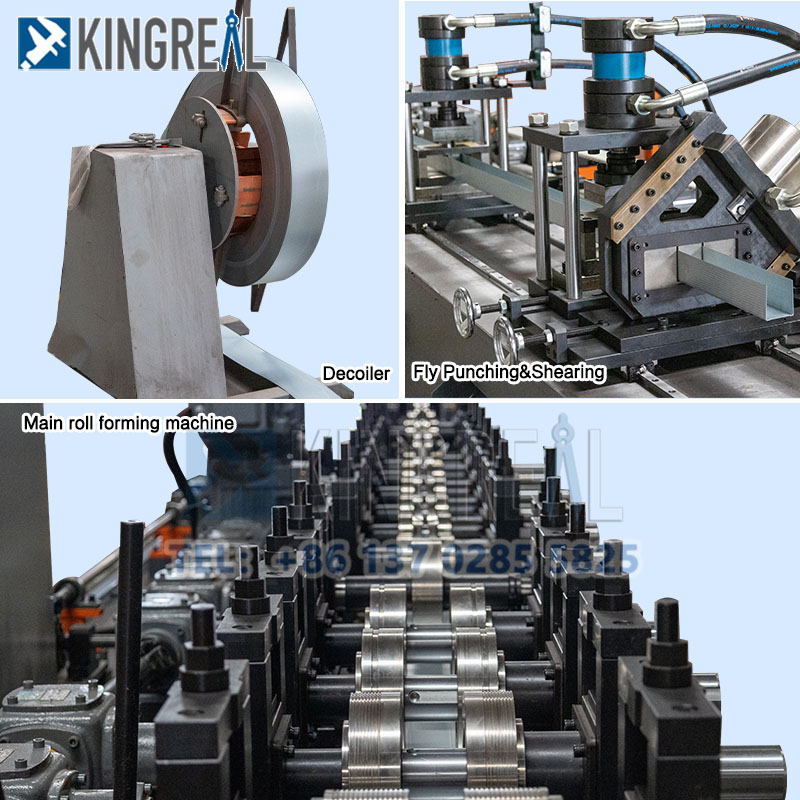

Decoiler-Main Roll Forming Machine-Hydraulic Fly Punching and Shearing System-Product Table

2/ Working Principle of Metal Stud and Track Machine

The drywall profile machine operates in a highly automated system. First, the galvanized coils are fed into the decoiler, where they undergo pre-treatment before entering the main roll forming machine. The main roll forming machine's roller assembly is precisely designed to cold-bend the coiled material into the desired shape. A hydraulic punching and shearing system then precisely shears and punches the formed metal frame. Finally, the finished product is conveyed via a product table, completing the entire production line.

3/ Importance of Drywall Profile Machine in Drywall Framing System

1) Guaranteed production precision for drywall profile machine

KINGREAL metal stud and track machines utilize high-precision components to ensure durability and longevity. The blades in the roller assembly and shearing system are made of high-quality, hard materials with excellent wear resistance. This ensures excellent forming and shearing accuracy. Furthermore, KINGREAL conducts a test run after production to ensure that all performance parameters meet customer requirements and that the final product meets high standards in terms of length, width, and surface finish.

2) Capability of large-scale production for drywall profile machine

Metal studs and tracks are in high demand in construction projects and are essential components of drywall framing systems. KINGREAL metal stud and track machines can achieve a maximum production speed of 120m/min, enabling the production of large quantities of finished products in a short period of time. With the rapid development of society and the improvement in construction speed and efficiency, the demand for metal studs and tracks in many new buildings is increasing. KINGREAL drywall profile machines are well-suited to meeting this demand, ensuring the smooth progress of construction projects.

3) Flexibility in multi-specification production for drywall profile machine

Another major advantage of metal stud and track machines is their ability to produce finished products of varying specifications. By inputting different production parameters on the control panel, the roll forming machine's roller assembly automatically adjusts its width to produce metal studs and tracks of varying specifications. This flexibility eliminates the need for multiple metal stud and track machines; a single drywall profile machine can meet diverse specifications, significantly reducing investment costs.

4/Application of Metal Stud and Track Machine in Drywall Framing System

With the continuous development of the construction industry, prefabricated buildings have become an emerging architectural form. While requiring rapid construction and high quality, they also place higher demands on materials and components. Against this backdrop, studs and tracks produced by drywall profile machines have been widely used in drywall framing systems, achieving remarkable results. Drywall framing systems are structural systems designed and manufactured to specific needs, primarily consisting of studs and tracks, surface materials, and connectors. This system is not only lightweight and easy to assemble, but also offers excellent seismic resistance. In prefabricated buildings, studs and tracks produced using metal stud and track machines are widely used in residential buildings, office buildings, and other locations.

Using studs and tracks for assembly, the drywall framing system provides stable support, bearing the weight of the building itself. This system not only enhances the overall structural strength of the building but also significantly improves sound insulation. By splicing studs and tracks, the drywall framing system effectively separates individual offices, remains independent of the main building structure, and can be flexibly arranged and adjusted according to needs. The drywall framing system produced using a drywall profile machine not only speeds up renovations but also allows for flexible and effective spatial division. Compared to traditional brick walls, studs and tracks are faster to construct, use more environmentally friendly materials, and effectively reduce the overall weight of a building. Furthermore, due to their excellent sound insulation, studs and tracks are ideal for dividing office and residential spaces, providing a comfortable living and working environment.