The importance of cz purlin machine in construction industry

2025-09-09 12:00The cz purlin machines provided by KINGREAL not only offer efficient and stable production capabilities but also meet market demand for diverse products. With the rapid development of the modern construction industry and the increasing use of steel structures, cz purlin roll forming machine have become a crucial piece of equipment in the industry. This article will explore in detail the importance of cz purlin machines in the construction industry, analyzing their technical advantages and market applications, and gaining an in-depth understanding of their contribution to improving construction efficiency and reducing production costs.

The Importance of CZ Purlin Roll Forming Machine

CZ purlin roll forming machines are primarily used to produce c purlin and z purlin, which are widely used in structural support beams and wall beams for buildings and factories. In recent years, with the continuous upgrading of building materials, CZ purlin, due to its high strength, light weight, and easy installation, has gradually replaced traditional concrete structures and become a popular choice in the construction industry. The rapid development of the construction industry has led to a continuous increase in demand for cz purlin. CZ purlin not only effectively reduces the weight of buildings but also improves structural stability. Especially in projects such as large factories, warehouses, and commercial buildings, the use of cz purlins significantly shortens construction cycles and improves efficiency. KINGREAL cz purlin machines offer a variety of specifications tailored to market needs, aiming to help customers reduce production costs. These cz purlin roll forming machines not only meet market trends but also offer high quality and efficiency, meeting the needs of customers across diverse projects.

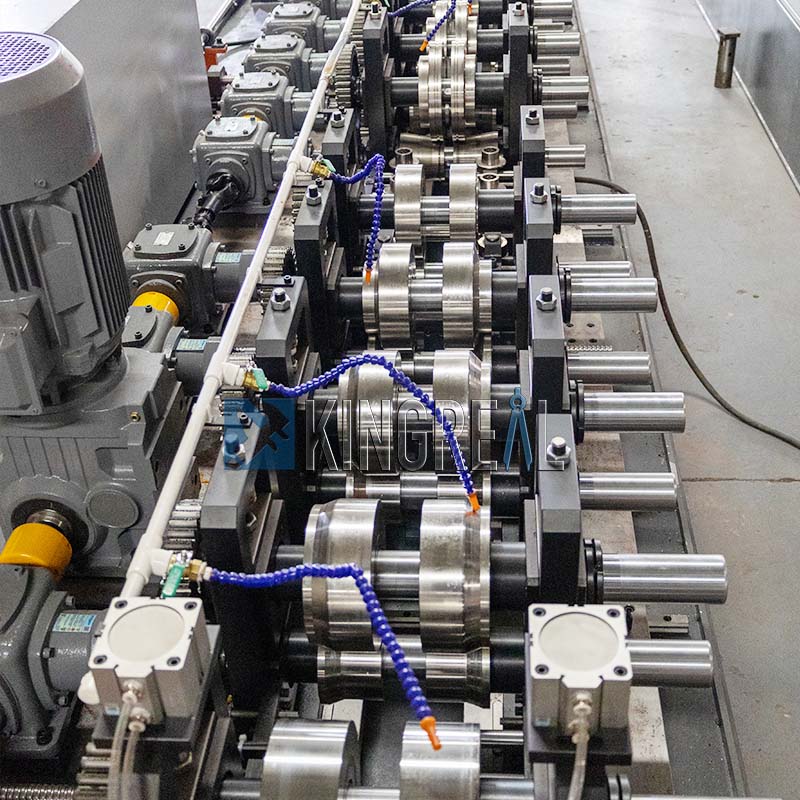

Technical Advantages of KINGREAL CZ Purlin Machines

1. Highly Efficient Production Capacity

KINGREAL cz purlin roll forming machines can accommodate steel thicknesses from 1mm to 4mm and offer up to 30 automatic punching configurations. This flexibility enables the production line to quickly respond to market changes and meet individual customer needs. The advanced steel changing mechanism allows for rapid switching between different specifications, significantly improving production efficiency.

2. Precise Quality Control

All processing is done in a single pass, ensuring accurate dimensions and positioning. The high-quality control system makes parameter setting simple and convenient, ensuring a high degree of automation. The servo motors within the cz purlin machine precisely adjust production parameters to ensure high-quality finished products.

3. Fully Automated Production

KINGREAL cz purlin roll forming machine supports fully automated operation, with all production processes controlled by an industrial computer. This automated model not only improves production efficiency but also reduces the need for manual intervention, resulting in a more stable production process.

Advantages of CZ Purlin Roll Forming Machine

1. Powerful and Diverse Powertrain

Multiple motors are strategically arranged within the cz purlin machine, each with its own distinct functions. They work together to provide robust power for c purlin conversion, thickness adjustment, and side-roll gap adjustment. The efficient motors ensure stability even at high speeds.

2. Intelligent Control for CZ Purlin Machine

The control cabinet, the "brain" of the cz purlin roll forming machine, is equipped with a Siemens main drive inverter and servo motor drivers, ensuring precise control of the production process. Customers can easily set production parameters through a simple user interface, enhancing the user experience.

3. Flexible Thickness and Side-roll Gap Adjustment

Customers can quickly adjust the desired material thickness with simple on-screen operations. This flexibility not only shortens production setup time but also ensures uniform force distribution during the rolling process, guaranteeing high-quality forming.

Applications of CZ Machines

1. CZ purlin roll forming machine in housing construction

In housing construction, CZ purlin serves as the primary supporting structure, effectively improving building safety and stability. Using cz purlin machines, builders can quickly produce steel that meets design requirements, improving construction efficiency.

2. CZ purlin roll forming machine in factories

CZ purlin also plays a vital role in factory building construction. Its lightweight and high-strength properties significantly reduce overall costs, while the flexibility of steel structures allows for greater design diversity.

3. CZ purlin machine in other industrial applications

CZ purlin roll forming machines can also be used in other industrial projects, such as power facilities and transportation infrastructure. The CZ purlin produced by these cz purlin machines can meet various industrial needs and provide strong support.