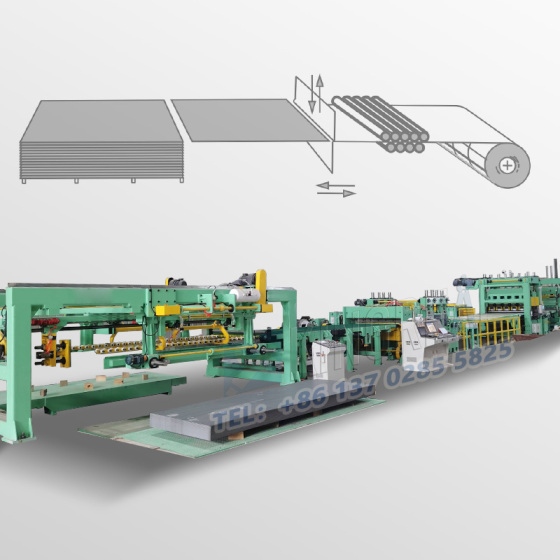

Heavy Duty Cut To Length Line

KINGREAL Heaby Duty Cut To Length Line is specifically designed for metal thick plate(Up To 20MM Thickness Coil) processing, which requires a high level of decoiler, leveling and shearing equipment.

- KINGREAL

- China

- Information

- Download

KINGREAL Heavy Duty Cut To Length Machine Video

Description Of Heavy Duty Cut to Length Line

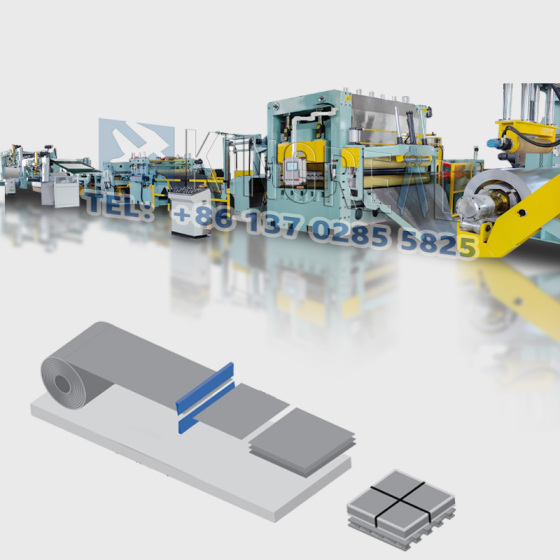

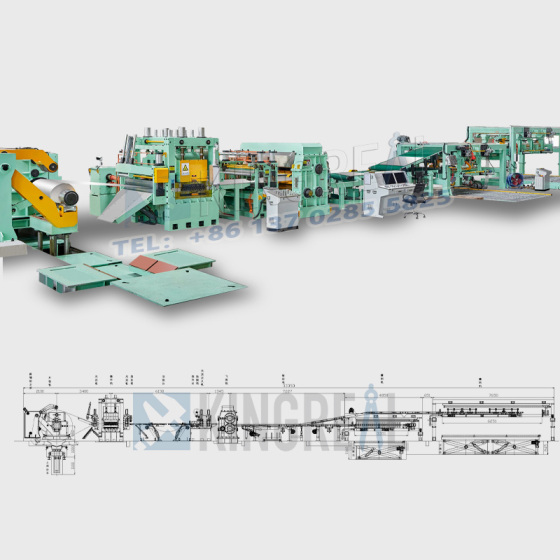

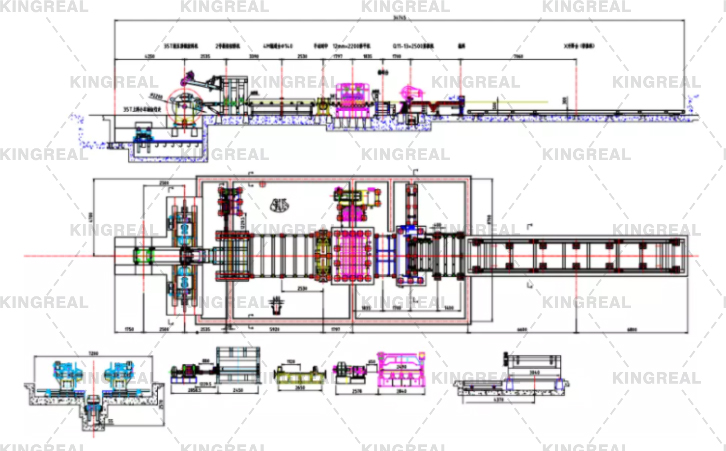

KINGREAL Heavy Duty Cut to Length Line, heavy gauge cut to length machine is specially designed for uncoiling, leveling, cutting and stacking of metal coils with a thickness of up to 10-25mm. The processing of thick sheet metal coils requires a higher level of components, KINGREAL specialized design the components and equipment, which are adapted to the shearing process of high-thickness coils.

★Precision leveling and stress elimination

The Heavy Gauge Cut To Length Line uses a four-roller leveling machine (4Hi leveler) to eliminate the internal stress of the coil through the staggered arrangement of multiple rollers. The leveling accuracy can reach ±2 mm/m², ensuring the flatness of thick plates (8-25 mm) and avoiding subsequent cutting deformation.

★High-precision cut-to-length

The Heavy Gauge Cut To Length Machine is equipped with an encoder speed measurement system and a servo motor-driven cut-to-length mechanism. The cutting length accuracy is ±1 mm, and the diagonal tolerance is controlled within 2 mm. It is suitable for customized cutting needs of 800-12000 mm.

★Adaptive tension control

The Heavy Gauge Cut To Length Production Line maintains stable material tension through a hydraulic or pneumatic clamping system, and cooperates with the frequency conversion motor speed regulation to prevent the thick plate from slipping or deflecting during high-speed (0-25 m/min) operation.

Main Processes of Cut to Length Machine

Trolley For Loading Coil -- Hydraulic Decoiler -- Feed Roller -- Straightener-- Loop Bridge -- Side Guide Device -- Servo Straightening Machine -- Fly Shearing Machine -- Transition Table -- Auto Stack

Parameter of Cut to Length Line Machine

◆Raw material : Q235 HR

◆Sheet thickness : 5.0~16.0mm

◆Sheet width : 900~2000mm

◆Machine input net width: 2000mm

◆Outer diameter of coil : Φ1000~Φ2200mm

◆Inner diameter of coil : Φ550~Φ760mm

◆Maximum coil weight : 30T

◆Stacking length : 1000~12000mm

◆Operating speed : 0~25m/min

◆Total power : ~500KW

Features of Cut to Length Line Machine

1. KINGREAL Heavy Gauge Cut to Length Line applicable feed materials include aluminum, galvanized and hot rolled steel, can meet your diverse production needs.

2. KINGREAL Thick Plate Cut to Length Machine uses a five-roller leveling and two-roller clamping and feeding arrangement, to ensure the accuracy of production.

The vertical guide rollers are positioned on both sides of the sheet width direction, this adapts well to accommodate varying sheet widths.

3. Strength and sturdiness are extremely important for thick plate Cut to Length Line Machine. KINGREAL use high-strength materials to build the fuselage and accessories, and strictly control the manufacturing process. After the Cut to Length Machine is produced, our professional technical team immediately tests the machine to ensure that every component is in perfect condition.

High Precision Metal Cut To Length Machine

|  |

KINGREAL's heavy gauge cut to length line has excellent shearing capacity and can process a variety of metal coils with thickness ranging from 0.3mm to 20mm, including copper, aluminum, stainless steel, hot-rolled, cold-rolled and other metal raw materials commonly found on the market. This wide processing range enables KINGREAL's metal cut to length line to meet the diverse needs of different customers and become an ideal choice for various metal processing industries.

KINGREAL Technical Team

KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Cut to Length Line, from design - production - installation - after-sales, our team has an excellent standard. KINGREAL has established the localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India and etc.. Localized service points in other countries are also in progress.

KINGREAL Successful Projects

As an experienced cut to length production line manufacturer, KINGREAL has successfully sold various types of cut to length production lines around the world, covering Turkey, Egypt, Qatar, Russia, India and other countries. KINGREAL's metal cut to length lines are not only technologically advanced, but also meet the specific needs of different markets and provide customers with efficient solutions.