Simple Cut To Length Line

Simple Cut To Length Machine is specially designed by KINGREAL to save the factory area for installing the machine, and at the same time reduce the customer‘s investment as much as possible. It is one of our most distinctive cut-to-length production lines

- KINGREAL

- China

- 100 Days

- 9999

- Information

- Download

KINGREAL Simply Cut To Length Line Machine

Description Of Simple Cut To Length Machine

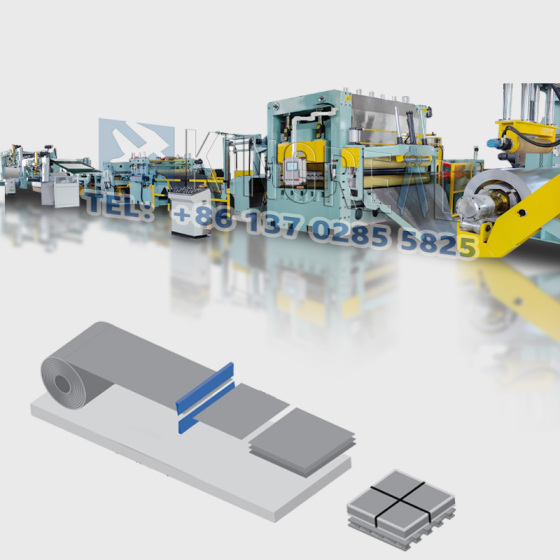

The cut to length line is mainly used in the production process of cutting coils of different material thicknesses into specified widths. Generally speaking, as a large-scale coil processing equipment, the cut to length production line is not a small investment in terms of the price of the machine, the area required for factory installation, and the cost of later maintenance.

In order to help customers who do not have particularly high production requirements to reduce investment costs, KINGREAL specially designed this simple cut to length machine. This production line simplifies most of the equipment as much as possible without affecting the basic production functions, and realizes an integrated production structure.

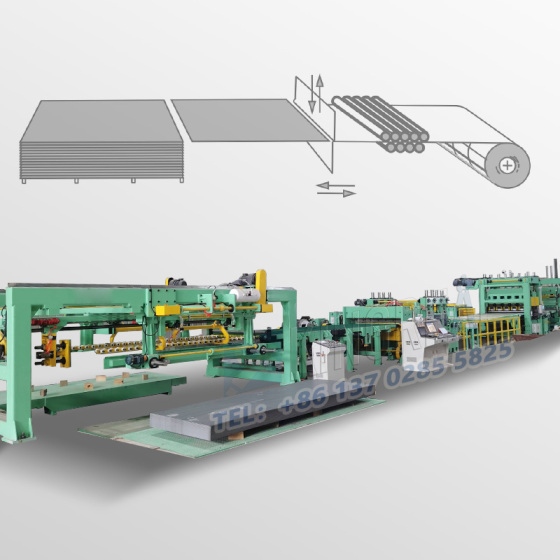

Working Flow Of Econonical Cut To Length Machine

Hydraulic Decoiler -- Feeding Roller -- Leveling Machine -- Shearing Machine -- Convey -- Automatic Stack

Technical Specification Of Cut To Length Line

◎Raw Material: Metal,Steel,Stainless and so on

◎Coil Thickness: 0.3-3mm

◎Coil Width: 1500mm

◎Coil Weight: 20T

◎Roller Material: GCr15

◎Blade Material: GCr15

Feature Of Cut To Length Machine

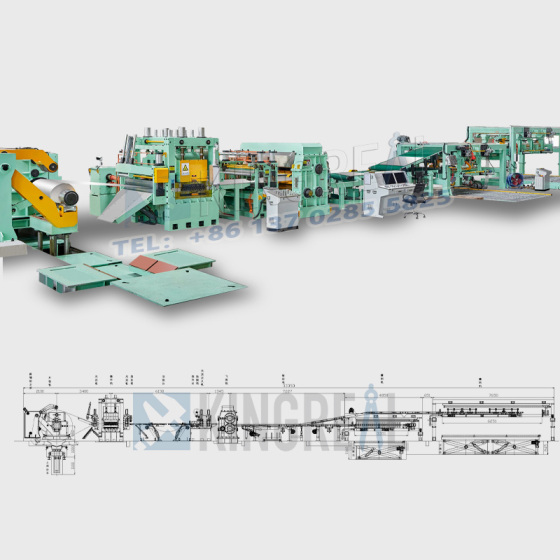

1. Decoiler System

The coil slitting line decoiler unit adopts hydraulic collapsible roller, no harm to the bottom layer of material.

It can be stretch uncoiling or manual unloading, effectively prevent the material from deflection and scratching.

2. Cut To Length Capability

Cut to length line uses a sheet-shaped fixed knife and a reciprocating moving knife. The fixed knife usually has a warped portion to form a cutting edge, while the moving knife completes the shearing action by moving forward and backward or up and down. The gap between the upper and lower blades can be precisely controlled by manually adjusting the eccentric sleeve or gear rack mechanism to adapt to different thickness plates.

3. Full Automation Stacking

KINGREAL designs automatic stacking machine configuration the cut-to-length production line to realize automatic stacking production.

The biggest advantage of this machine is that it can reduce investment costs and meet the needs of low-budget customers.On the one hand, the production line simplifies a large part of the equipment and reduces the production cost of the machine; On the other hand, the integrated production line features can realize the effect of putting into production without building a foundation.

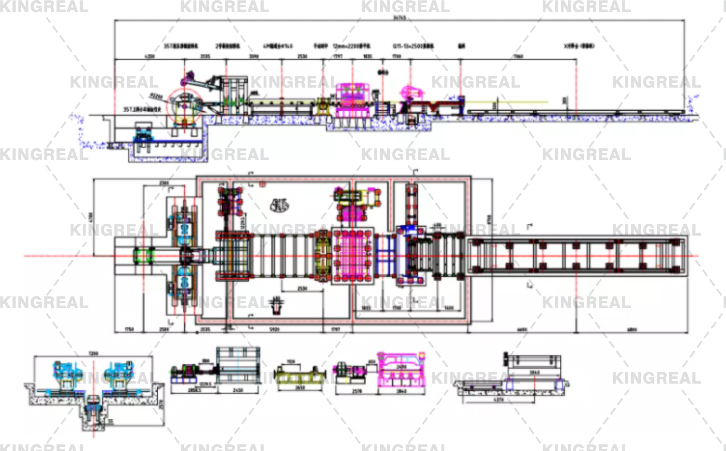

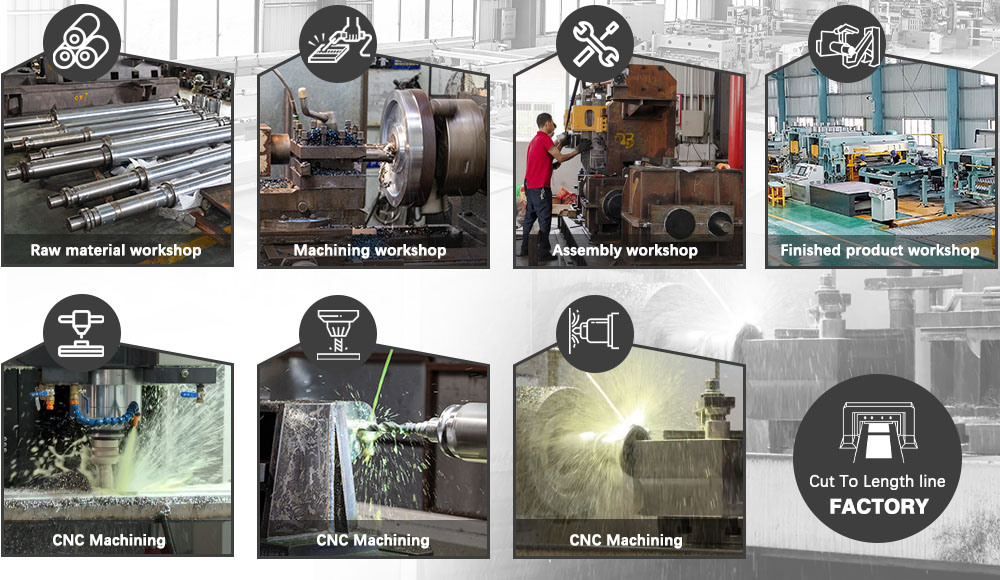

KINGREAL Cut To Length Line Factory

KINGREAL has its own production plant, which includes a frame casting shop, a CNC control shop, a parts machining shop and an assembly shop. In order to ensure the production quality of the cut to length machines, the whole line will be tested and adjusted in the factory. KINGREAL welcomes all customers to visit our factory.