- Home

- >

- Products

- >

- Cut-To-Length Line

- >

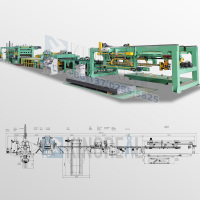

Cut-To-Length Line

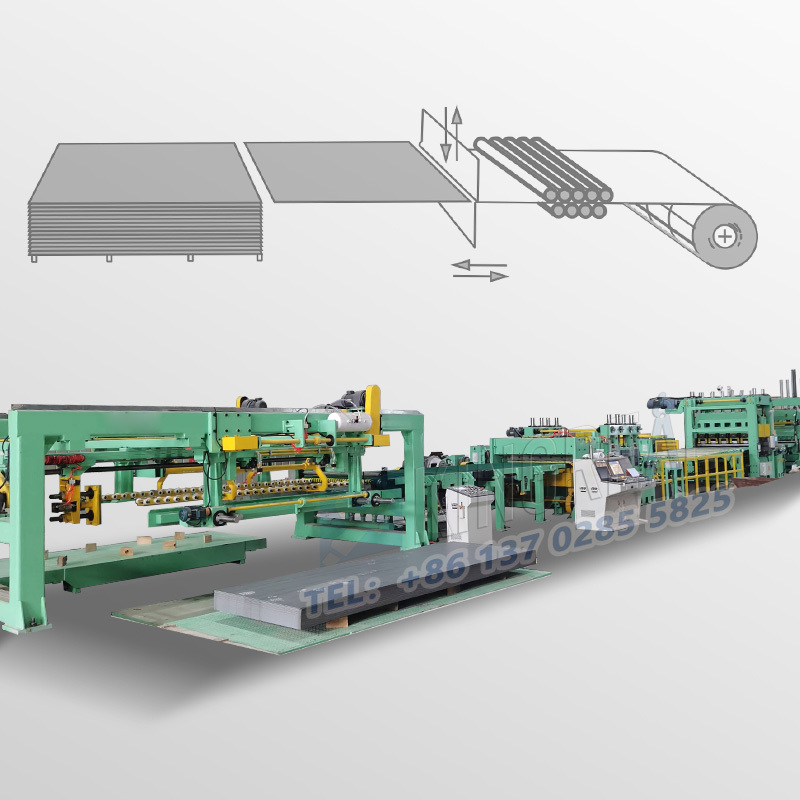

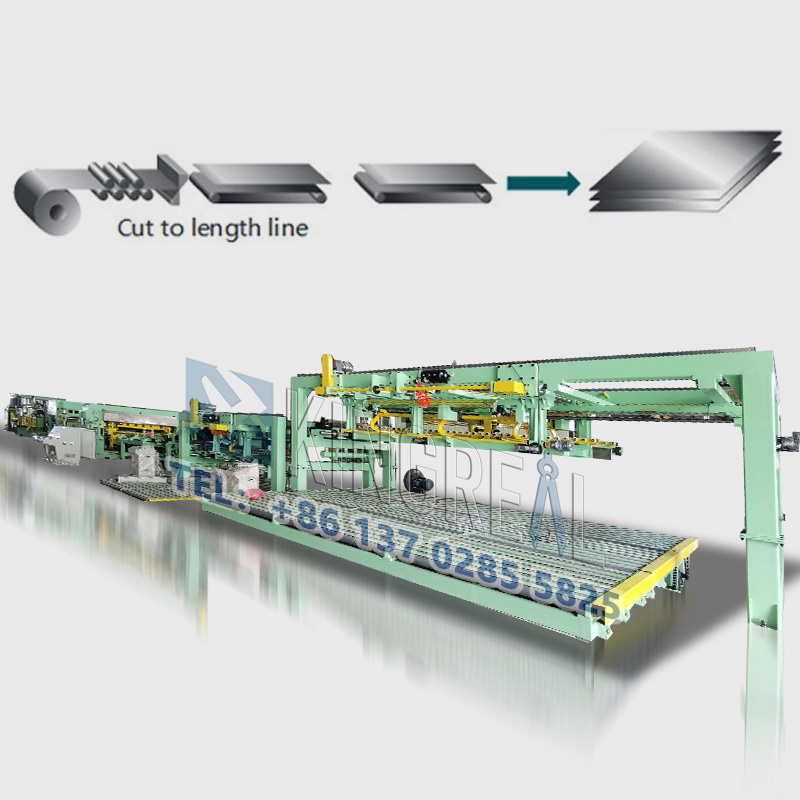

A cut-to-length line is a common piece of coil processing equipment in the metalworking industry. Cut-to-length lines is primarily used to level and shear steel coils into the customer's desired dimensions. The steel plates processed by this specialized cut-to-length lines equipment are widely used in industries such as steel, aluminum, machinery manufacturing, automotive, and construction.

- Information

- Download

Description of Cut-To-Length Lines

A cut-to-length line is a common piece of coil processing equipment in the metalworking industry. Cut-to-length lines is primarily used to level and shear steel coils into the customer's desired dimensions. The steel plates processed by this specialized cut-to-length lines equipment are widely used in industries such as steel, aluminum, machinery manufacturing, automotive, and construction.

Cut-to-length Line Manufacturer -- KINGREAL

KINGREAL is a cut-to-length machine manufacturer with over 20 years of experience, specializing in the research and development, design, sales, and manufacturing of cut-to-length lines. KINGREAL is committed to providing customers with customized, high-precision cut to length machine solutions that meet precise production needs, helping them achieve more efficient metalworking.

KINGREAL maintains high standards for innovation and quality during its design and manufacturing processes. As a result, its cut-to-length lines have earned widespread acclaim from customers for their precision, reliability, and stable performance. Currently, KINGREAL cut-to-length machines have been successfully shipped to customer factories in countries including Saudi Arabia, Russia, the United States, Brazil, and Indonesia, significantly improving their production efficiency.

KINGREAL is committed to providing customers with optimal cut-to-length line solutions and hopes to establish long-term partnerships with them while maintaining efficient and reliable production levels.

If you have any cut to length machine requirements or would like more information, please feel free to contact KINGREAL. We will provide a perfect cut to length machine manufacturing solution based on your drawings and actual production needs.

Common Parameters for Cut-to-Length Lines

★Coil Material: Steel/Stainless Steel/Carbon Steel/Galvanized Steel/Silicon Steel/Aluminum Alloy/Copper Alloy

★Coil Thickness : 0.2 - 25 mm

★Coil Width: 500 - 2000 mm

★Coil Weight: Up to 35 tons

★Cut-To-Length Lins Speed: 20 - 80 m/min

★Leveling Accuracy: ±0.1 mm - ±0.5 mm

★Cutting Accuracy: ±0.1 mm - ±0.2 mm

★Total Power Requirement: 80 kW - 300 kW

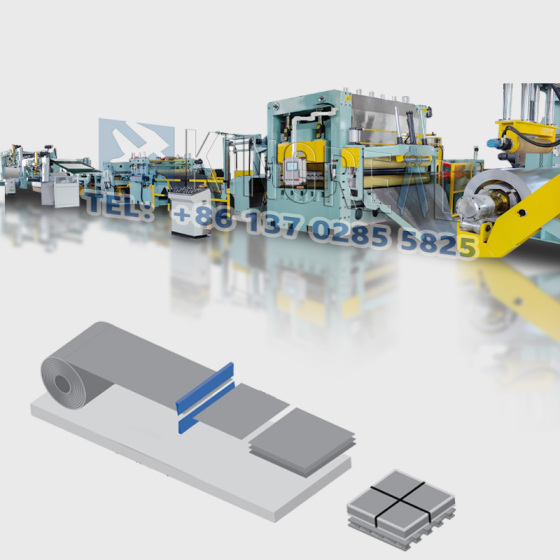

Working Process of Cut-To-Length Machine

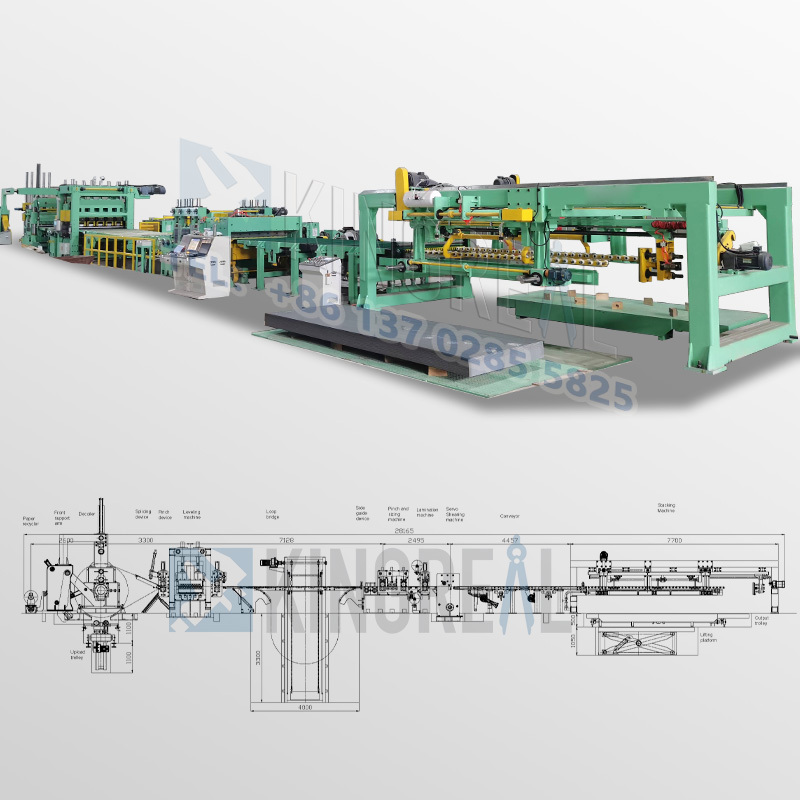

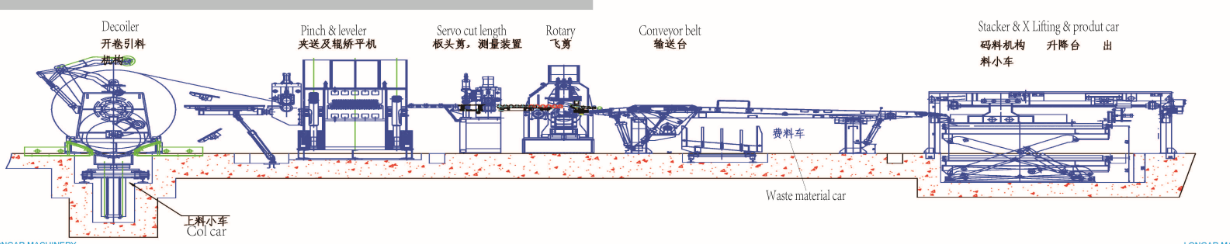

Trolley to load the coil -- Decoiler to feed coil -- 2-rollers pinch feeder to feed coils forward -- 6-layers levelling machine for precision levelling -- High precision cut to length machine -- Belt conveyer to convey sheets -- Auto stack

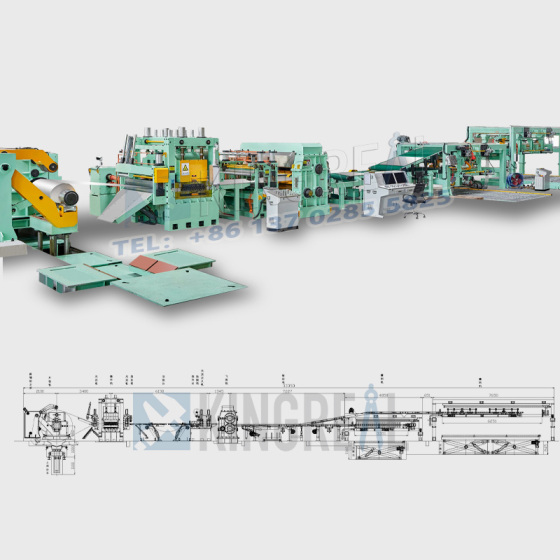

Main Component of Cut-To-Length Machine

1) Decoiler for cut-to-length line

The hydraulic decoiler features a double-support, double-cone pressure mechanism that securely clamps the steel coil. The movement of the machine base at each end is driven by hydraulic cylinders, providing both drive and centering functions. Pneumatic disc brakes are installed on both spindles of the decoiler, enhancing safety and precision during operation.

2) Feeder and pre-leveler for cut to length machine

The feeder and pre-leveler features a two-roller clamping feeding system and a five-roller leveling mechanism. A motor drives the upper and lower rollers through a reducer and a distributor box, connected by a universal joint. Hydraulic cylinders adjust and press the upper roller, ensuring precise control of feeding and leveling.

3) Side guide for cut-to-length line

This side guide mechanism guides the steel strip before it passes through the CNC length gauge, ensuring precise alignment. The system consists of four transition rollers, a sturdy frame, six guide rollers, and a synchronization mechanism to ensure accurate positioning of the strip throughout the entire process.

4) Length-measuring cutting machine for cut-to-length line

This system is used to cut steel plates to precise lengths. Driven by a servo motor, it ensures fast cutting speeds. The cutting blades are interchangeable for maximum economic efficiency. Furthermore, the cutting process is performed from bottom to top, effectively preventing damage to the conveyor belt.

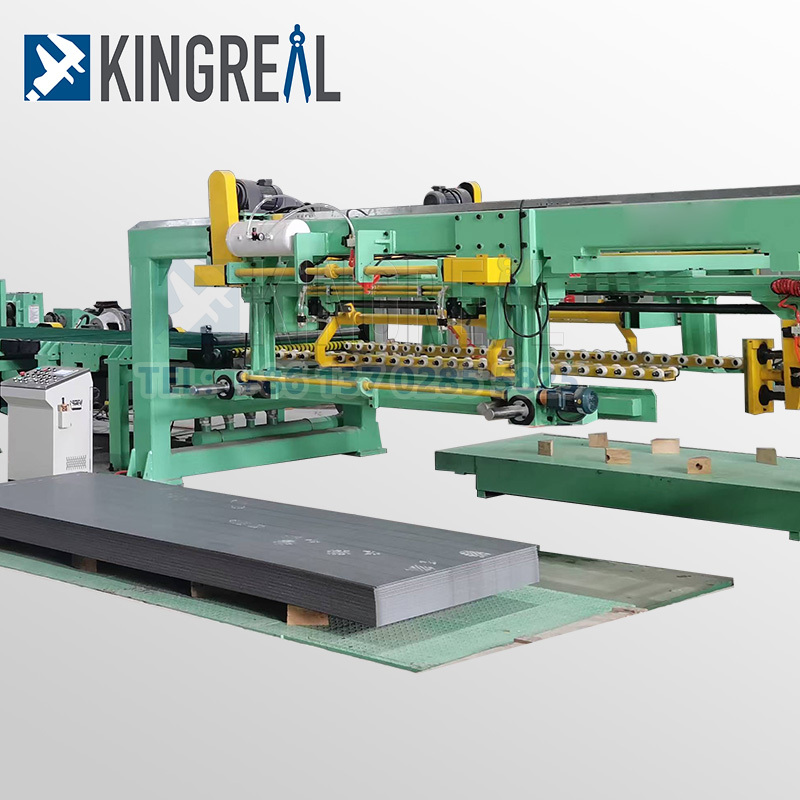

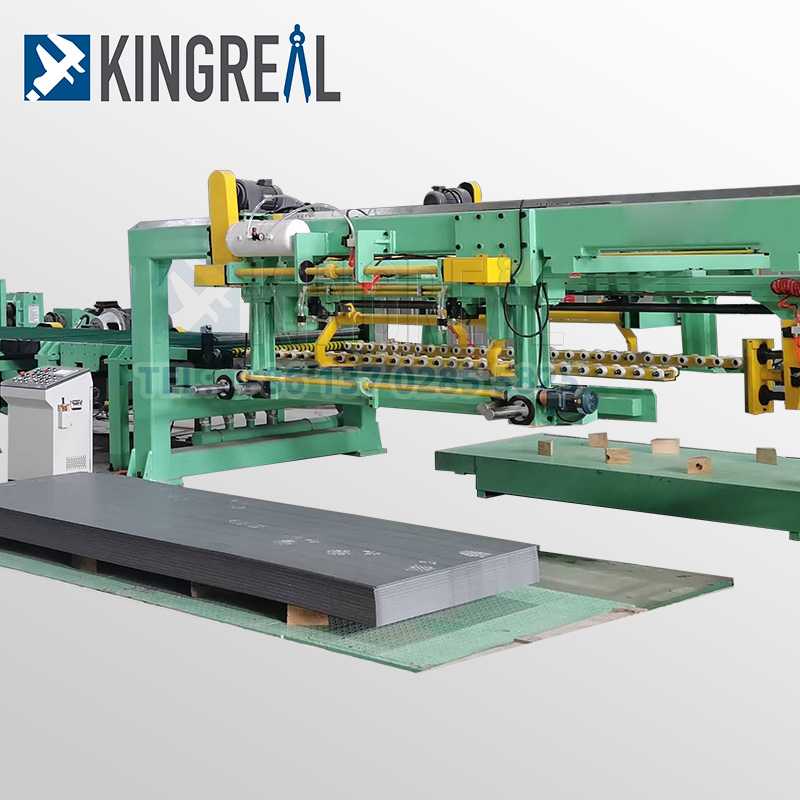

5) Stacker for cut to length machine

The stacker collects finished steel plates from the conveyor and automatically and neatly stacks them. Pneumatic and hydraulic mechanisms work together to ensure an orderly and precise stacking process.

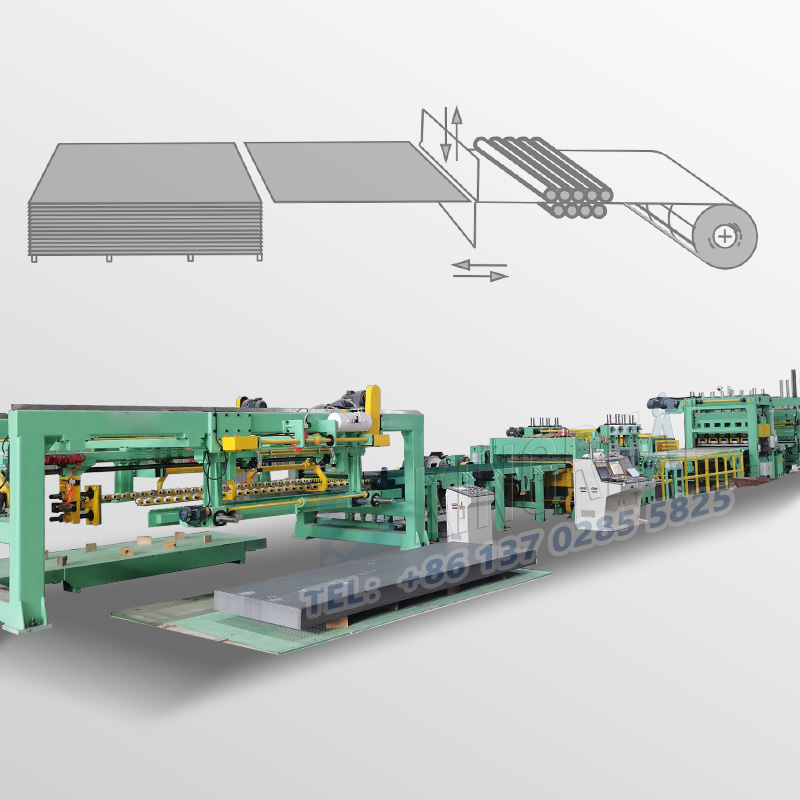

Various Cut-to-Length Line Solution

KINGREAL designs a variety of cut to length machines to meet the specific requirements of various industrial applications, tailored to customers' varying coil thickness requirements. The following are our featured cut-to-length line types:

(1) Different cut-to-length line according to coil thickness

★Heavy gauge cut-to-length line

The heavy gauge cut-to-length line is designed for processing thicker metal coils ranging from 6mm to 25mm. Featuring higher shearing forces and more powerful equipment, this heavy gauge cut to length machine can handle heavy materials and meet the demands of high-intensity applications. Its advanced hydraulic system and efficient tool design ensure exceptional stability and precision during the shearing process, making it suitable for applications in aviation, marine, and heavy machinery.

★Medium duty cut-to-length line

The medium duty cut to length line is suitable for processing metal coils ranging from 0.3mm to 6mm in thickness and is widely used in industries with stringent requirements for dimensional and surface quality. This medium duty cut to length line flexibly processes a variety of materials, including aluminum, stainless steel, and carbon steel, ensuring excellent flatness and surface finish. Its efficient automation streamlines the production process, reduces the need for manual operation, and improves production efficiency.

★Light gauge cut-to-length line

Designed for processing metal coils with thicknesses ranging from 0.2mm to 3mm, these thin coil shears offer exceptional cutting accuracy and stability. This light gauge cut-to-length line is ideal for handling delicate materials such as thin stainless steel and aluminum alloys, and is widely used in the electronics, home appliance, and decoration industries. Its sophisticated blade design and advanced control system ensure that the material is not damaged during the shearing process.

(2) Customized cut-to-length line

★Compact cut to length machine

The compact cut to length line is a compact, efficient designed to minimize footprint while maintaining high productivity and precision. Ideal for factories with limited space, this compact cut to length machine can integrate multiple functional modules, such as uncoiling, leveling, shearing, and stacking, optimizing line layout and increasing overall production capacity.

★Cut-to-length line with dual stacker

Equipped with a dual stacker, this cut to length machine can process two sheets of material simultaneously, significantly increasing production speed and overall productivity. This innovative design allows the line to complete more tasks simultaneously, reducing production costs and improving efficiency, making it ideal for production environments with high throughput requirements.

(3) Different cut-to-length line according to cutting system

KINGREAL cut to length line utilize a variety of shearing types to accommodate varying material thicknesses, properties, and production requirements. These diverse shearing methods not only achieve more precise cuts, but also improve production efficiency and minimize material waste. Whether it's rotary shearing cut to length machine, fly shearing cut to length line, swing shearing cut to length line or fixed shearing cut to length line, KINGREAL offers a solution to meet our customers' diverse needs.

Advantages of KINGREAL Cut-to-Length Line

①Personalized design cut-to-length line

KINGREAL cut to length machines are custom-manufactured based on customer drawings and actual production needs, ensuring they meet the specific requirements for cutting a wide range of metal sheet metal to length. KINGREAL guarantee that each cut-to-length line delivers efficient and stable cutting performance, focusing on improving production efficiency and reducing material waste.

②Advanced control system for cut to length machine

KINGREAL cut-to-length lines utilize an advanced automated control system, including a PLC system, servo motors, and high-precision encoders. This cutting-edge technology ensures precise cutting to the desired length, significantly improving overall production efficiency and ensuring accuracy for different material types.

③High-performance leveling machine for cut-to-length line

KINGREAL cut to length machines are equipped with dual or multi-roller leveling devices to effectively eliminate ripples and bends in metal sheets, ensuring each sheet is perfectly flat and uniform. KINGREAL leveling machine is ideal for producing high-quality finished products that meet our customers' stringent quality standards. For customers with extremely high requirements for sheet straightness, KINGREAL can also equip the cut-to-length line with two leveling machines to ensure optimal results.

④Precision cutting for cut to length machine

KINGREAL cut-to-length machines offer cutting accuracy within ±0.1mm and are suitable for processing a variety of materials, including cold-rolled steel, stainless steel, and aluminum alloys. The cutting blades are made of high-strength alloy steel, durable and wear-resistant, ensuring high performance, long-term reliability, and minimal maintenance costs.

⑤Surface protection for cut to length machine

During the design and manufacturing process, KINGREAL prioritize surface protection to maintain the integrity of the metal sheets. Components such as chrome-plated rollers, polyurethane rollers, feeders, and blowers play a vital role in protecting the sheet surface. These protective components effectively prevent scratches and damage during cutting and handling, ensuring a high-quality surface finish.