Coil Processing Equipment Solution

KINGREAL offers a comprehensive range of coil processing equipment solutions, from sheet metal leveling machine for smoothing metal surfaces, to metal cut to length line for cutting sheet metal to desired lengths, to metal slitting machines for slitting metal coils into narrow strips of desired widths. Finally, KINGREAL has also developed a steel coil packaging line for use with a metal slitting machine, providing a complete set of efficient and complete solutions for coil processing.

- KINGREAL

- Information

- Download

KINGREAL offers a comprehensive range of coil processing equipment solutions, from sheet metal leveling machine for smoothing metal surfaces, to metal cut to length line for cutting sheet metal to desired lengths, to metal slitting machines for slitting metal coils into narrow strips of desired widths. Finally, KINGREAL has also developed a steel coil packaging line for use with a metal slitting machine, providing a complete set of efficient and complete solutions for coil processing.

KINGREAL coil processing equipment supports processing a wide range of materials, from hot-rolled,cold-rolled,carbon,steel, stainless steel and non-ferrous metals. KINGREAL customizes coil processing equipment based on customers' operational objectives, ensuring precision and efficiency at every stage of metal processing, meeting diverse applications and complex requirements.

▎Video About Metal Slitting Machine

▎Introduction to Metal Slitting Machine

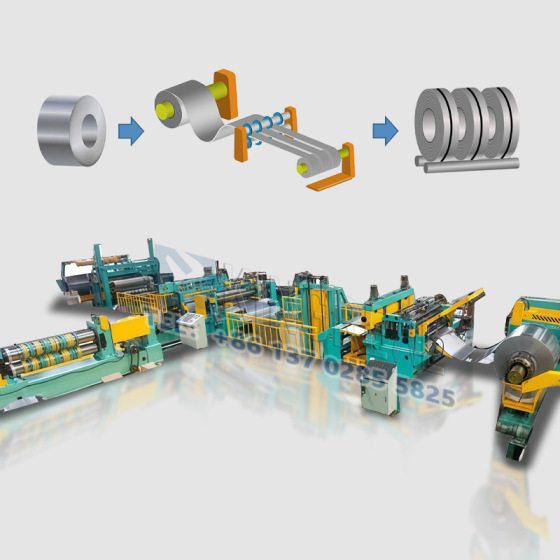

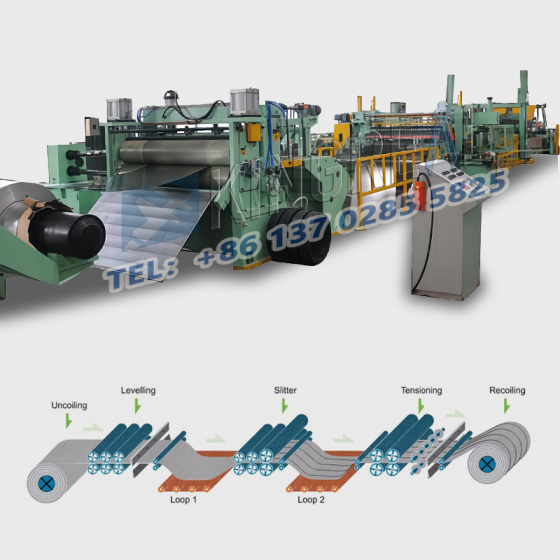

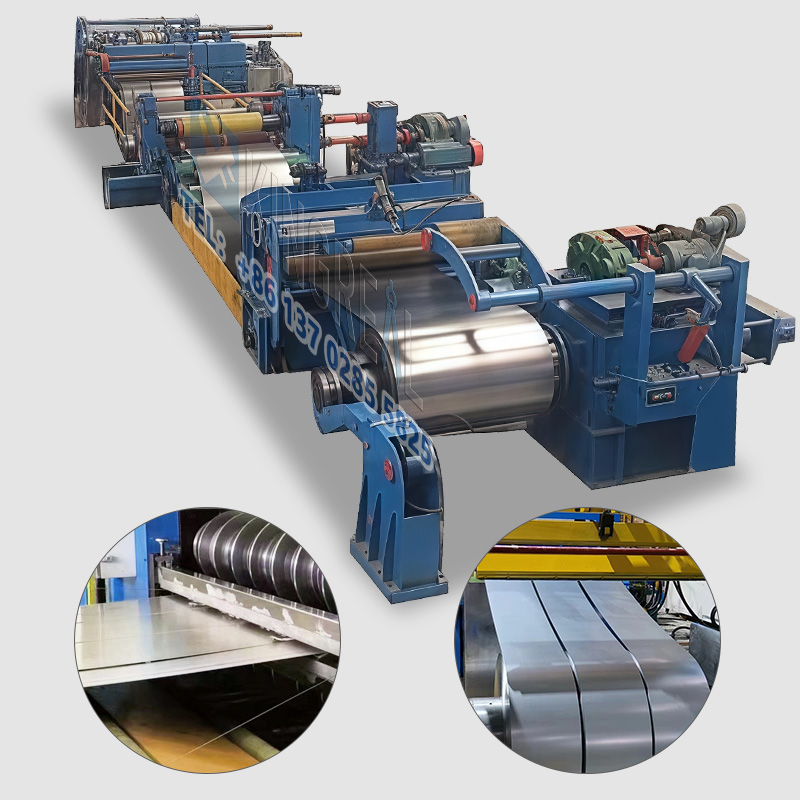

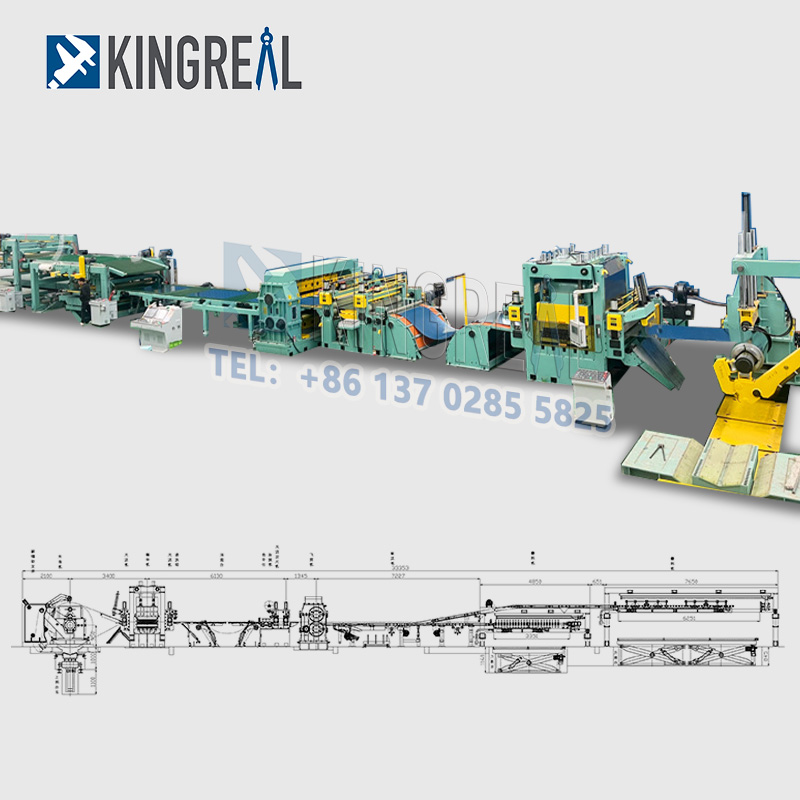

Metal slitting machines cut metal coils lengthwise and rewind the slit strips into coils. This metal slitting machine is suitable for processing a variety of metal materials, including cold-rolled and hot-rolled carbon steel, silicon steel, and stainless steel. A metal slitting machine typically consists of a loading carriage, a decoiler, a traction leveler, a slitting machine, a scrap rewinder, a tensioning mechanism, a recoiler, and a discharge device.

In the metal slitting machine, the blades on the blade shaft rotate under the influence of a motor, using the sharp edges of the blades to cut the metal sheet lengthwise. The distance between the upper and lower blade shafts can be adjusted to accommodate metal coils of varying widths, ensuring precise and stable cutting. A control system manages the machine's start, stop, and speed, enabling automated management.

▍Advantages of KINGREAL Metal Slitting Machine

1)High Slitting Capacity: Metal slitting machines can process multiple strips simultaneously in a single operation, achieving higher output. The metal slitting machine can slit up to 40 narrow strips simultaneously, significantly improving production efficiency.

2)Fast Production: Utilizing an efficient motor drive system and precision blade design, the metal slitting machine’s production speed is significantly increased, reaching up to 230 m/min, or even higher, meeting customers' needs for large-scale production.

3)Customized Design: KINGREAL offers customized metal slitting machine solutions tailored to specific customer needs. These include light duty slitting machine, medium duty slitting machine, and heavy duty slitting machines designed for varying coil thicknesses. KINGREAL also offer stainless steel slitting machine, silicon steel slitting machine, copper slitting machine, hot rolled slitting machine, cold rolled slitting machine, and PPGI slitting machines designed for various metal materials. KINGREAL also offer dual slitter head slitting machines and belt tension metal slitting machines designed to meet precision requirements.

▎Video About Steel Coil Packaging Line

▎Introduction to Steel Coil Packaging Line

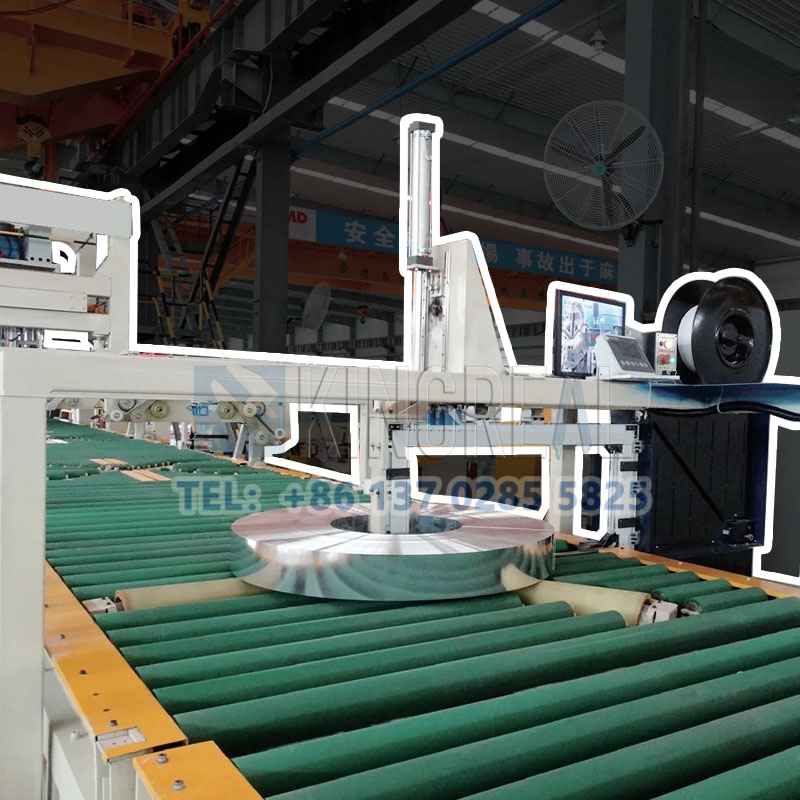

Steel coil packaging lines are a key component of coil processing equipment solutions and typically consist of a coil strapping machine, a coil tilter station, and a vertical coil packaging line. Steel coil packaging lines can be seamlessly integrated with metal slitting machines, significantly improving automation levels. With the steel coil packaging line, the entire line only requires two to three workers, saving over 40% in manpower compared to the five people required for a conventional metal slitting line (three operators + two balers). Furthermore, the automated steel coil packaging line effectively reduces operator error, improving reliability and safety.

The steel coil packaging line provides comprehensive protection for narrow strips, preventing damage during transportation and storage caused by improper packaging, ensuring that products arrive in pristine condition at the customer's factory.

▎Advantages of KINGREAL Steel Coil Packaging Line

1)Seamless Integration: The steel coil packaging line seamlessly integrates with the metal slitting machine. KINGREAL designed linkage system initiates the pre-packaging process 30 seconds before rewinding is complete. It automatically measures the roll diameter (with an accuracy of ±1mm) and calculates the required packaging material length. The moment rewinding stops, the wrapping head precisely positions itself at the roll seam and begins wrapping. The entire process requires no human intervention, and the entire process, from slitting to packaging, takes just 90 seconds.

2)Efficient Production: KINGREAL offers customized steel coil packaging line manufacturing solutions tailored to customer production needs. The narrow strips are baled along the steel coil packaging line, the stripped steel is vertically flipped by a turning machine and transported to the baling station via a conveyor roller. The conveyor roller is equipped with a high-precision weighing device, and label printing and labeling are completed at this station. After the steel is radially bundled at the baling station, it is accurately transported to the transfer station. It can increase the production line output by up to 30%.

▎Video About Metal Cut to Length Line

▎Introduction to Metal Cut to Length Line

Metal cut to length lines are used to shear metal coils into flat sheets of desired length through a series of steps (decoiler, flattening, and cut-to-length) and then stack them. A metal cut to length line typically includes a loading trolley, decoiler, leveler, feeder, shearing machine, conveyor, and stacker. The metal cut to length line's primary operating principle is to use cutting tools to transversely cut metal coils, achieving precise cuts.

▎Advantages of KINGREAL Metal Cut to Length Line

1)Wide Processing Range: The metal cut to length line can cut coils ranging in thickness from 0.2 to 25 mm. This wide processing range allows it to adapt to diverse production needs and satisfy diverse applications across various industries. Whether it's fine cutting of thin plates or heavy-duty processing of thick plates, KINGREAL metal cut to length lines can efficiently complete both tasks.

2)Customized Metal Cut to Length Lines: Customizable metal cut to length lines are available. KINGREAL design metal cut to length lines with varying parameters and performance based on specific customer production needs. For example, KINGREAL offers light duty cut to length lines, medium duty cut to length lines, and heavy duty cut to length lines based on coil thickness. KINGREAL also offers fly shearing cut to length line, swing shearing cut to length line, rotary shearing cut to length line, and fixed shearing cut to length line based on different shearing methods. KINGREAL also offers stainless steel cut to length line, steel cut to length line based on different materials. KINGREAL also offers metal cut to length lines equipped with dual levelers, dual stacking tables, and laminating devices to meet specific customer production needs.

3)High Cutting Precision: KINGREAL metal cut to length lines ensure high cut-to-length accuracy and high sheet flatness, enabling neat stacking. This cutting accuracy is achieved not only through advanced equipment technology but also through KINGREAL rigorous control over the production process.

▎Video About Sheet Metal Leveling Machine

▎Introduction to Sheet Metal Leveling Machine

Sheet metal leveling machines are a key component of coil processing equipment, their primary function being to smooth uneven metal materials. After the material to be smoothed enters the sheet metal leveling machine through the inlet, it undergoes multiple positive and negative bends on upper and lower rows of straightening rollers, gradually reducing the material's original curvature and degree of bending, ultimately achieving reliable flatness. Furthermore, the sheet metal leveling machine effectively eliminates internal stress in the material, laying the foundation for subsequent processing.

Sheet metal leveling machine consist of several key components, including a sturdy frame, upper and lower roller systems, intermediate/support rollers, precision adjustment mechanisms, a drive system, guides, and a control system. Generally speaking, the smaller the pitch and diameter of the leveling rollers, the better the leveling effect. Increasing the number of leveling rollers also increases the number of alternating bends, thereby improving leveling quality.

▍Advantages of KINGREAL Sheet Metal Leveling Machine

1)Multi-Material Compatibility: Whether it's ceiling panels, precision components, copper parts, perforated metal, metal rods, or metal strips, KINGREAL sheet metal leveling machines can efficiently handle them.

2)Customized Configuration: Based on the customer's specific leveling requirements, including the thickness of the metal material, KINGREAL can design a sheet metal leveling machine with a different number of leveling rollers. Furthermore, the sheet metal leveling machine can be equipped with a variety of configurations, including compacting rollers, induction-enhanced rollers, and upper roller propulsion. Customers can choose the appropriate configuration to optimize leveling results.

3)High Flattening Precision: After flattening, the flatness can reach 0.01mm, ensuring the ideal flatness of the output metal sheets for subsequent processing.