Silicon Steel Slitting Line

Silicon steel slitting lines are specifically designed for the precise longitudinal cutting of wide, curved or non-curved silicon steel materials, and are widely used in industries such as automotive, silicon steel processing, and transformer manufacturing.

- KINGREAL

- China

- Information

- Download

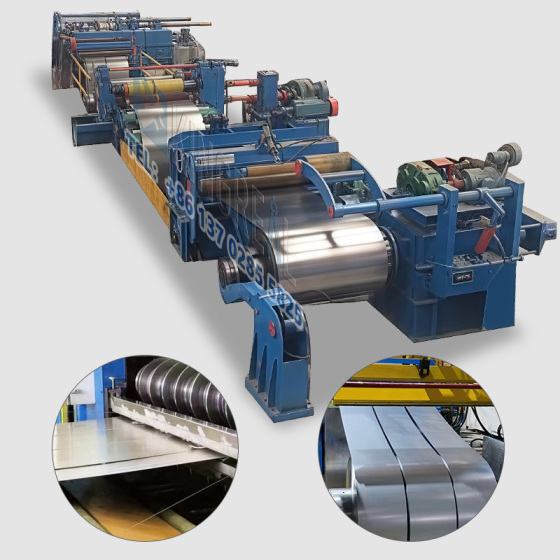

Description of Silicon Steel Slitting Line

The silicon steel slitting line is specifically designed for the precise longitudinal cutting of wide silicon steel materials. It effectively cuts curved or non-curved silicon steel materials into strips of the required width and winds them into coils. This silicon steel slitting machine is particularly suitable for processing silicon steel with a thickness between 0.15 and 0.50 mm and is widely used in industries such as automotive, silicon steel processing, and transformer manufacturing.

The silicon steel slitting machine is designed to meet demanding industrial requirements, featuring a high surface finish, robust construction, and long service life. Its adjustable speed and high cutting accuracy continue to be favored by customers.

Parameter of Silicon Steel Slitting Line

Item | Value |

Steel thickness | 0.15 to 0.5mm |

Decoiling expansion range | Φ480 to Φ520mm |

Max. sheet | 1250mm |

Coil weight | 5 to 8 ton |

Slitting shaft | Φ125mm |

Blade outer diameter | Φ250mm |

Slitting strip | 20 to 1250mm |

Slitting speed | 50 to 120m∕min |

Burr | ≤0.02mm |

Straightness | ≤0.2mm/2m |

tolerance | ±0.1mm |

Slitting blade | 12 sets |

Power consumption | 55kW |

Line dimension | 12.6m × 6.5m × 2m |

Gross weight | about 20 ton |

Power supply | 380V .AC. 50Hz |

KINGREAL Ultra-High Precision Silicon Steel Slitting Machine

Faced with the extremely high hardness and brittleness of silicon steel, the design and manufacturing process of silicon steel slitting lines must address the challenges of severe tool wear and high equipment precision requirements. Constantly innovating, the KINGREAL team finally produced a high-performance silicon steel slitting machine able of consistently and effectively generating small strips with great precision. This silicon steel slitting line was optimized according to the following standards during design and manufacturing to ensure the superior performance of each machine:

1. Material Requirements

With specific magnetic permeability and low-loss properties, the silicon steel slitting machine processed material must meet customer-required technological specifications or national standards. Maintaining processing quality depends on a surface devoid of visible dings, oxidations, oil stains, and scrapes.

2. Dimensional Accuracy

The silicon steel strips processed by silicon steel slitting line must meet the customer's precise requirements for width, thickness, and length. Dimensional deviations should be controlled within a reasonable range to ensure that the product fully meets design standards.

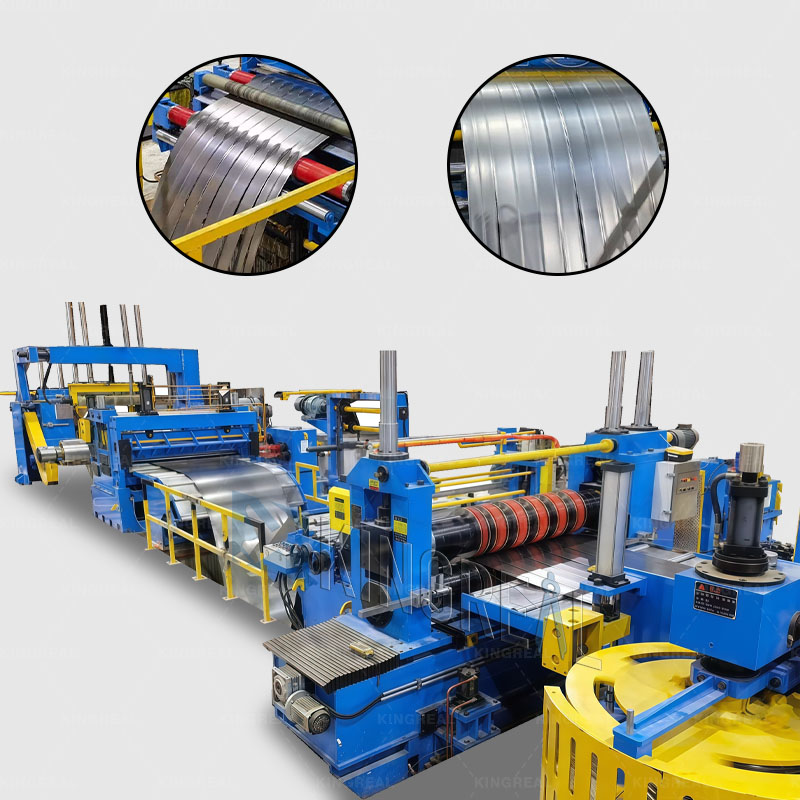

3. Surface Quality

The silicon steel strip's surface should be free from imperfections like scratches, dings, oxidation, or oil stains; hence, flat and smooth. Since the magnetic permeability and loss behavior of the material are directly affected by surface quality, it has to be rigorously monitored during processing.

4. Edge Straightness

The edges of the silicon steel strip must be straight, free from obvious defects such as curling, burrs, or cracks. Edge straightness has a significant impact on subsequent processing and forming of the silicon steel strip, therefore it must be strictly controlled during processing.

How Does KINGREAL Ensure Silicon Steel Slitting Line Precision?

1. Design stage of silicon steel slitting line

●Reasonable structural design for silicon steel slitting machine

To guarantee it can endure great strain and pressure during slitting, KINGREAL employs a strong frame architecture usually built of high-strength steel for the silicon steel slitting machine body. By box-type frame or gantry structure design, the rigidity and stability of the silicon steel slitting line are increased, hence minimizing the effects of vibration on processing accuracy. Additionally guaranteeing processing stability, KINGREAL arranges the several silicon steel slitting line parts to minimize vibration and sway. For instance, lowering the center of gravity and increasing the silicon steel slitting machine's resistance to interference by positioning heavy parts such as reducers and motors at the bottom of the equipment.

●Precise component machining for silicon steel slitting line

High-precision machining using CNC equipment ensures that sizes and surface quality satisfy the micron level during the manufacturing of important parts like the cutter shaft, cutter holder, and guide rollers. Additionally, silicon steel slitting machine parts are subject to thorough quality testing to guarantee they all satisfy design specifications, therefore avoiding the installation of inadequate components.

●Using high-quality materials for silicon steel slitting line

KINGREAL pays particular attention to material selection when manufacturing key components for silicon steel slitting machines. For instance, to increase hardness and wear resistance, the cutter shaft uses alloy steel of excellent quality and receives heat treatment; guide rollers are made of aluminum alloy or stainless steel to guarantee good surface finish and corrosion resistance. Highly wear-resistant materials are employed for commonly worn parts such as blades and rubber pressure rollers, and these are regularly swapped to guarantee the consistent and stable operation of the silicon steel slitting line.

2. Manufacturing and assembly stage for silicon steel slitting line

●Strict quality control for silicon steel slitting machine

KINGREAL has set up a tight quality management system under which every process is monitored and examined to make sure the processing quality of components satisfies design specifications. Especially during assembly, high-precision tools and processes are used to ensure that each component is installed accurately and securely. For machine connections, torque wrenches are used to tighten bolts, and laser alignment instruments are used to adjust the transmission system to ensure smooth and reliable power transmission.

●Precise debugging and calibration for silicon steel slitting machine

After assembly, KINGREAL performs precise debugging and calibration to ensure that the parallelism of the cutter shaft, the blade clearance, and the performance of the tension control system, among other performance indicators, meet design requirements. Precision measuring tools such as micrometers and feeler gauges are used to verify the slitting material, and the silicon steel slitting line is optimized and adjusted promptly based on the measurement results.

●Quality acceptance and testing for silicon steel slitting machine

Before the silicon steel slitting line leaves the factory, KINGREAL conducts comprehensive quality acceptance and testing on the silicon steel slitting machine to ensure that the product performance indicators fully meet relevant standards and customer requirements. Simulated testing under actual production conditions, such as long-term continuous operation and slitting tests with different materials, ensures the stability and reliability of the silicon steel slitting machine, allowing customers to confidently put it into production.

KINGREAL Diverse Design Solutions for Silicon Steel Slitting Machines

To meet the specific needs of different customers, KINGREAL offers diverse silicon steel slitting line design solutions. KINGREAL design team refines silicon steel slitting machine parameters based on customer project requirements and technical specifications of different countries and regions, including processing materials, material thickness, width, weight, number and specifications of narrow strips, to ensure that each silicon steel slitting machine can accurately meet the customer's production needs. In addition, KINGREAL also provides customized silicon steel slitting line configuration solutions based on special customer requirements, such as equipping the silicon steel slitting machine with coil packaging line, laminating device, or protective shield, ensuring high silicon steel slitting line integration and a more efficient production process.

With the development of electric vehicles and new energy technologies, the demand for silicon steel slitting lines in these emerging industries is increasing. The high-quality narrow strips produced by silicon steel slitting machines can be widely used in many fields, such as home appliance manufacturing, small and medium-sized electromechanical products, new energy vehicles, and large-scale electromechanical products. Specifically, non-oriented silicon steel narrow strips are typically used in large electromechanical equipment and household appliances, while oriented silicon steel narrow strips are mainly used in products such as transformers that require high magnetic permeability materials. These applications demonstrate the diversity and adaptability of silicon steel slitting line designs.

FAQ About Silicon Steel Slitting Line

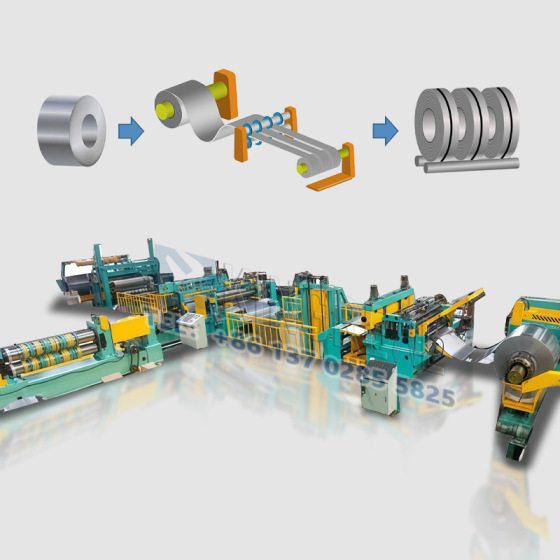

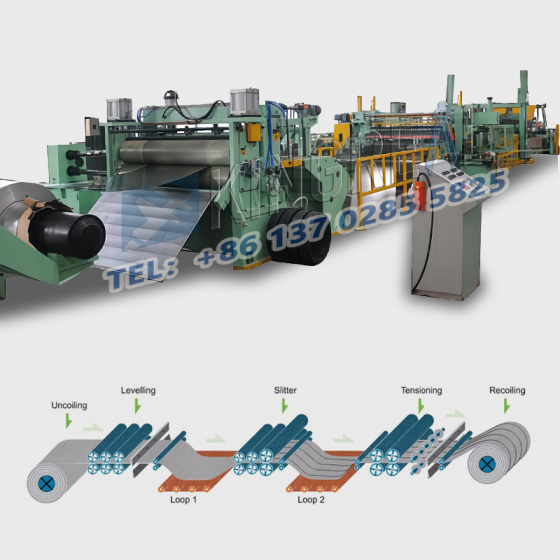

1.How does a silicon steel slitting line work?

A silicon steel slitting machine uncoils a metal coil, slices it into narrower strips using rotary knives, and recoils the strips for further processing or shipping.

2.Do you sell only standard silicon steel slitting lines?

No, KINGREAL silicon steel slitting machines are built according to customers specifications,using top brand name components.

3.What information do I need to provide if I want to order a customized silicon steel slitting line?

Materials, thickness, coil weight, inner and outer diameter of the coil, capacity of the decoiler and recoiler, application of the slitting strips, or any project details that will help us provide the silicon steel slitting machine best suited to your needs.

4.Do your silicon steel slitting lines comply with European CE standards and ISO certification?

Yes, KINGREAL silicon steel slitting machines fully complies with all relevant CE marking and ISO certifications, ensuring top-notch quality, safety, and reliability.

5.What is the lifespan of slitting blades?

The lifespan of slitting blades is influenced by production volume, operating conditions, and material properties. Variations in blade composition and application typically affect longevity.