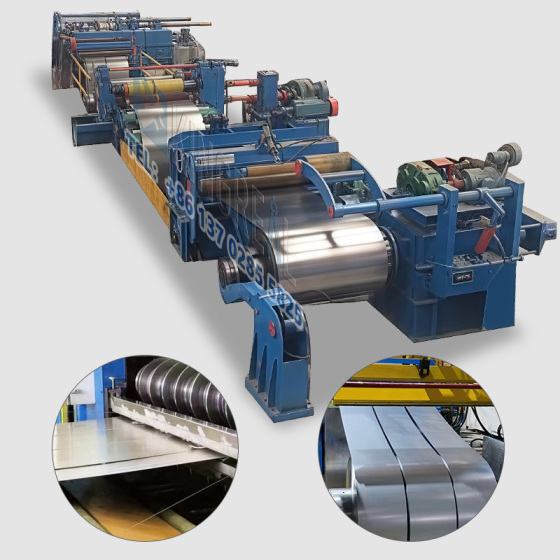

(0.3-3)×1600MM Coil Slitting Machine

KINGREAL (0.3-3)×1600MM Coil Slitting Machine used to slitting the metal sheet coil into specified widths and finally rewinding, which can process different materials including stainless steel, galvanized steel, cold rolled sheet and hot rolled sheet, and the applicable thickness range is 0.3-3MM.

- KINGREAL

- China

- 120 Days

- 9999

- Information

- Download

Video About Coil Slitting Machine

(0.3-3)×1600MM Coil Slitting Machine Description

KINGREAL (0.3-3)×1600MM Coil Slitting Machine used to slitting the metal sheet coil into specified widths and finally rewinding, which can process different materials including stainless steel, galvanized steel, cold rolled sheet and hot rolled sheet, and the applicable thickness range is 0.3-3MM, common coil width is 1600MM, KINGREAL supports customized design of metal slitting machine.

KINGREAL can offer steel coil slitting machines with a variety of features and designs to meet the various manufacturing needs of its clients. Coil Slitting Machine can separated into thin plate coil slitting machines, medium plate coil slitting lines, and heavy gauge steel slitting machines based on material thickness; narrow strip slitting machines, double knife slitting head slitting machines, and 220/min high-speed slitting machines are divided based on production demand.

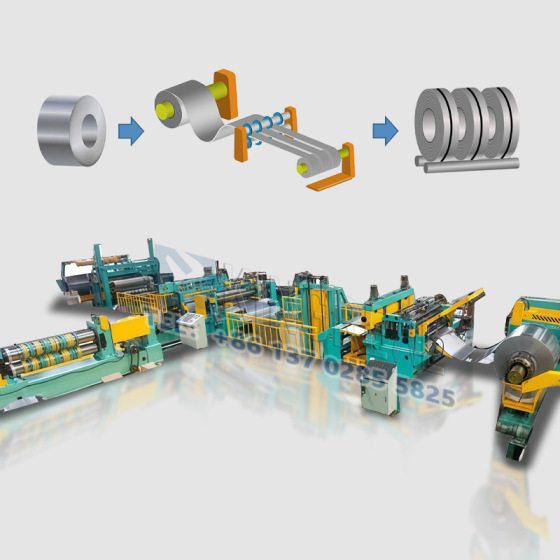

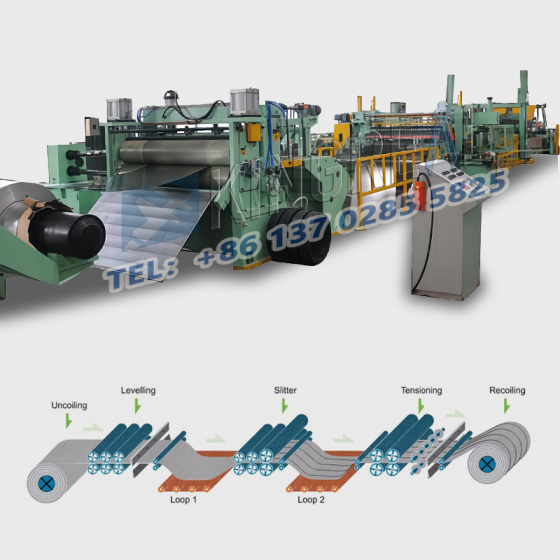

Working Process Of Coil Slitting Machine

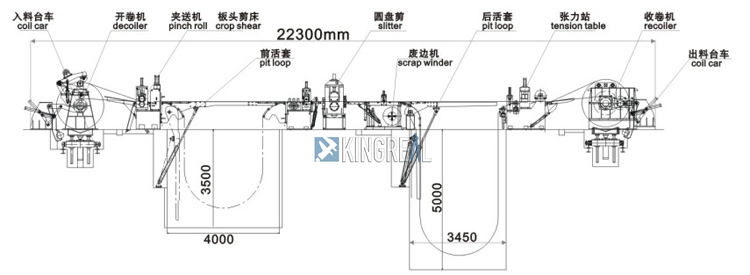

Trolley for coil loading → Hydraulic decoiler →2 rolls feeding and 3 rolls leveling → Loop bridge → High precision shearing machine → Side scrap recoiling →Pre-seperator and damping tension machine → Rewinding

Technical Specification

1. Processed Material Parameters

Raw material | Stainless steel, galvanized steel, cold rolled sheet and hot rolled sheet, etc. |

Coil thickness | 0.3-3.0mm |

Coil Width | 500-1600mm |

Coil weight | 25T |

Coil outer diameter | ≤Φ2000mm |

Coil inner diamete | Φ508mm、Φ610mm |

2. Coil Slitting Procution Line Parameters

Slitting Spee | 0~200m/min |

Strip through speed | 0~15m/mi |

Power | 380V/50Hz/3Phase |

Control | AC frequency conversion control |

Minimum slitting width | 50mm |

Width tolerance | ≤±0.05mm |

Line dimensio | About Length=30m, Width=12m |

Feature About Coil Slitting Machine

① Cantilever Decoiler

1. Function of Cantilever Decoiler: It carries steel coils, tightens and expands their inner diameter, uncoils and discharges them, or recycles them.

It is made up of a frame, spindle, expanding and contracting reel, unwinding and pressing device, auxiliary support, brake device, and power portion. It supports the coil plate and gives the steel strip tension.

2. Building

a) Main frame: composed of steel, A3 steel plate, and #45 steel forging bearing seat that is not deformed after welding and annealing;

b) Use a slider-type push-pull expansion reel form to raise and shrink the reel. It has four curved plates made of No. 45 steel, wire-cutting slider pairs, and an expansion diameter of ~<470mm–520mm (plus a rubber sleeve to reach ~\610mm). The reel's effective working length is 1650mm, and the overall mandrel makes sure that the reel up and down when the concentricity.

②High Speed Slitter Machine

Strip coils can be sliced longitudinally into different widths using a slitter machine. By varying the combined spacer, the sheared product's breadth can be freely adjusted. When adjusting the knife shaft, the upper shaft is adjusted like a worm gear while the lower shaft remains fixed.

The distance between the upper and lower shafts can be precisely controlled by the synchronized adjustment of the knife shaft spacing mode. The upper and lower knife shafts are fitted with a protective sleeve for the knife at the shaft end, and they use nuts for axial fastening. The primary device uses a motorized seat frame that may be opened and closed (motor-driven), making blade replacement easy.

③Pre-separation, Tensioner, Guide roller

1. Structure and purpose: After slitting, separate the strips to make it easier to close and avoid stacking when going through the tensioner. Two sets of dividing disks are present. To facilitate replacement and cleaning, the separating disk's shaft can be easily removed from the operating side.

2. The purpose of the guide roller, which is a seamless steel tube with a PU rubber covering and a Τ450mm dynamic balancing treatment, is to guide the belt into the winder.

3. Pallet device: consisting of drive system and frame. The purpose of the hydraulic drive structure used in pallet device lifting is to move the board toward the winder.

Why Choose KINGREAL?

★Rich Manufacturing Experience In Coil Slitting Production Line

KINGREAL is a seasoned manufacturer with over 20 years of production and sales expertise, with a focus on coil slitting machines. The company has successfully sold its machines to countries all over the world, such as the United Arab Emirates, Vietnam, Turkey, Russia, and India. widely recognized by customers.

★Professional Teamwork

KINGREAL has its own internal teams for production, sales, and technical support. KINGREAL are qualified to manage every stage of the procedure, including production, sales, and shipping.

★After Sales Service

To ensure the metal slitting machine is installed and used correctly, KINGREAL provides after-sales installation services both offline and online. While offline resources comprise KINGREAL sending professionals to the customer's local factory to provide on-site installation help, online resources include video lessons and extensive online engineering guidance.

KINGREAL Successful Projects

KINGREAL is committed to providing customers with a variety of metal slitting machine manufacturing solutions to meet the specific needs of different industries and customers. So far, KINGREAL's heavy duty metal slitting machines, high-speed metal slitting lines, steel slitting machines, metal slitting machines with lamination, double-slitter head metal slitting machines and other coil slitting machines have been successfully shipped to many countries, including Russia, India, Saudi Arabia, Turkey and the United Arab Emirates.