- Home

- >

News

This October, the Canton Fair was held as scheduled, attracting customers from all over the world to Guangzhou. KINGREAL factory, located just an hour's drive from the exhibition center, saw a significant increase in the number of customers it received. Customers from countries such as Israel, Singapore, Kuwait, and India visited the KINGREAL factory to learn about its various machines. In this article, KINGREAL will share some highlights from customer visits to the factory in October.

In modern warehouse management, pallet upright rack machines are crucial equipment, efficiently producing the profiles used to support pallet racking system. These pallet upright rack making machines primarily include Upright Rack Making Machine, Rack Box Beaming Machine, Pallet Rack Step Beam Machine, and Slotted Angle Making Machine, all of which provide the necessary support for racking systems.

With the rapid development of the logistics and warehousing industries, upright rack machines play an increasingly important role in modern manufacturing. Pallet storage rack machines are dedicated to the production of various types of upright racks, whose sizes and designs vary according to load-bearing capacity and style, including L-type (light load), C-type (medium load) and special C-type for heavy loads. In this article, KINGREAL will discuss in detail the main functions, structural components and advantages of upright rack machines in the industry to help you understand why choosing pallet storage rack machines is the key to improving production efficiency and product quality.

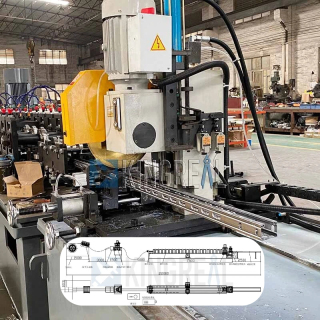

Warehouse Pallet Rack Machine, also known as pallet upright rack machine, warehouse pallet rack making machine, is a device for the production of different sizes and types of columns. It produces pallet racks that meet the needs of the shelf system through multiple workflows such as unwinding, leveling, punching, forming and cutting. These pillars support the shelving system, carrying a variety of goods and ensuring storage efficiency and safety in places such as warehouses, supermarkets and offices.