Drywall Profile Machine For Stud & Track

2025-11-06 18:06

"KINGREAL drywall profile machines are specifically designed for producing galvanized steel profiles for drywall applications. This highly efficient stud and track machine ensures precise manufacturing of studs and tracks, providing an ideal production solution for companies requiring large-scale production, high efficiency, and high-quality finished products. With the increasing demand for drywall materials in the construction industry, KINGREAL drywall profile machines are becoming the preferred choice for many companies.

This stud and track machine is manufactured using advanced technology, fully compliant with CE standards, and consists of multiple precision components, including a decoiler, roll forming machine, fly punching and shearing system, and output table. These components work together to achieve precise profile cutting, ensuring efficiency and accuracy in the production process. An advanced PLC system manages the entire production process, allowing users to remotely configure and monitor potential anomalies, further improving operational convenience and safety."

Customizable Drywall Profile Machine

KINGREAL drywall profile machine boasts exceptional adaptability, flexibly meeting diverse production needs:

↘The forming system can quickly adjust width, supporting the production of drywall profiles from 40mm to 150mm in width to accommodate varying market demands.

↘The roller's rapid adjustment function allows the stud and track machine to quickly switch between different drywall profile production, significantly improving production flexibility.

↘It can be integrated with an additional automatic packaging machine to achieve a fully automated process for packing, bundling, and stacking, reducing labor costs and increasing production efficiency.

↘Production speed is adjustable at any time, easily achieving drywall profile production rates up to 120 m/min.

↘Optional inkjet printers and lettering rollers enhance the competitiveness of drywall profiles in the market, making products more easily identifiable.

The production process begins with loading the metal coil into the decoiler, followed by rolling into the desired shape by the forming rollers, and then rapid punching and shearing to the required length via a fly punching and shearing system, ensuring efficiency and accuracy at every stage.

Description of Automatic Drywall Profile Machine for Stud & Track

KINGREAL drywall profile machines are technologically advanced and designed with users' actual needs in mind, ensuring efficient operation in various production environments. These stud and track machines not only boast high production capacity but also feature flexible operating systems that make the production of various types of drywall profiles easy and efficient.

In today's construction industry, with the increasing demand for drywall materials, builders and engineers have increasingly stringent requirements for drywall profiles. KINGREAL stud and track machines are specifically designed to meet these needs, efficiently producing standard drywall profiles as well as more complex structures, such as earthquake-resistant walls. The high production capacity of these drywall profile machines allows construction projects to proceed smoothly within tight schedules, ensuring timely project delivery.

KINGREAL automatic stud and track machines, with their advanced technology, high production capacity, and flexible operating systems, are the ideal choice to meet the needs of the modern construction industry. KINGREAL drywall profile machines provide customers with high-performance stud and track systems, facilitating the smooth progress of construction projects.

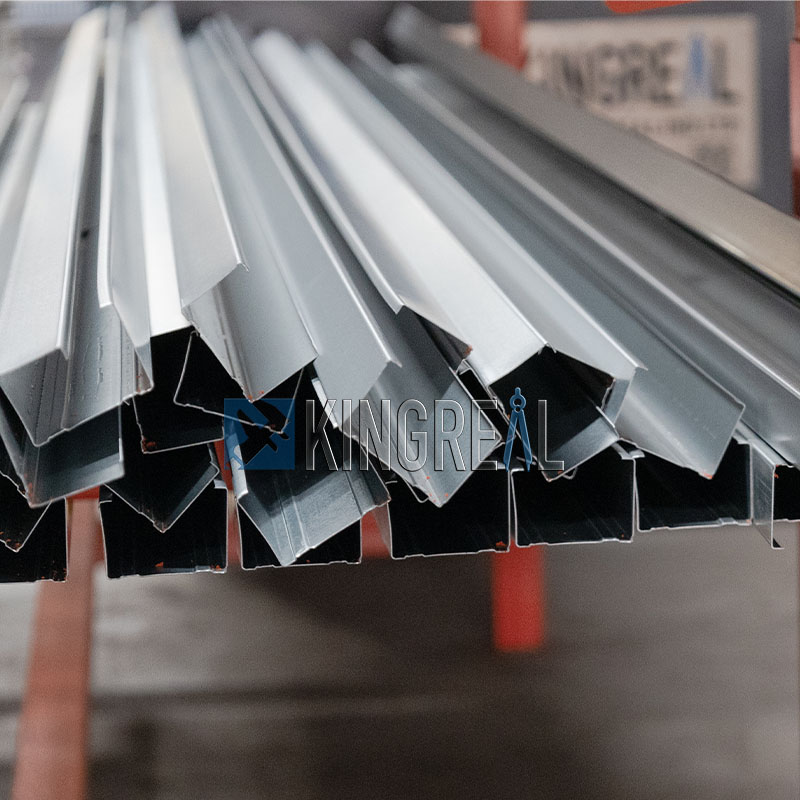

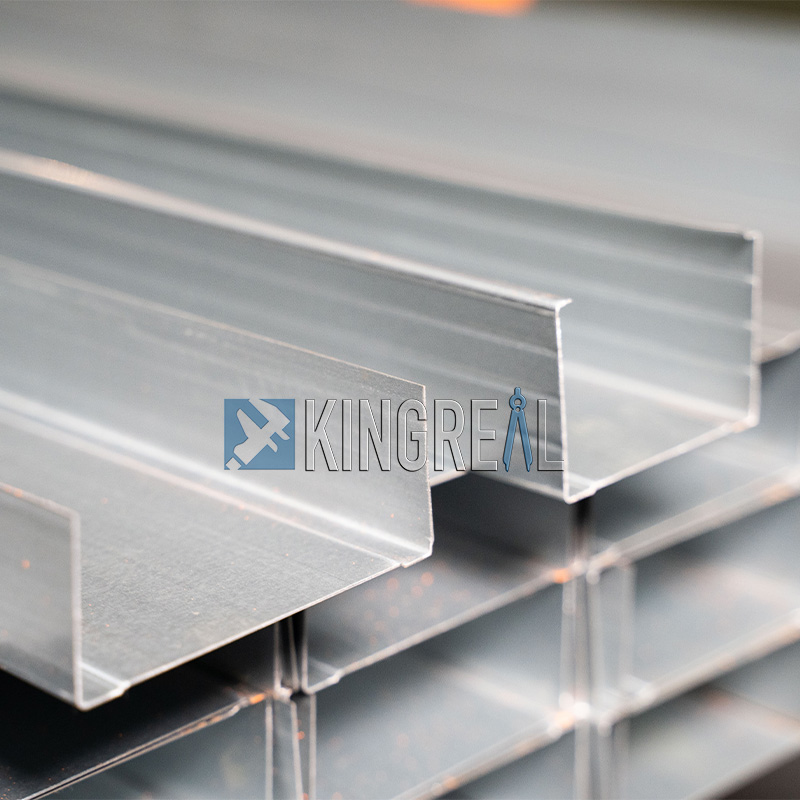

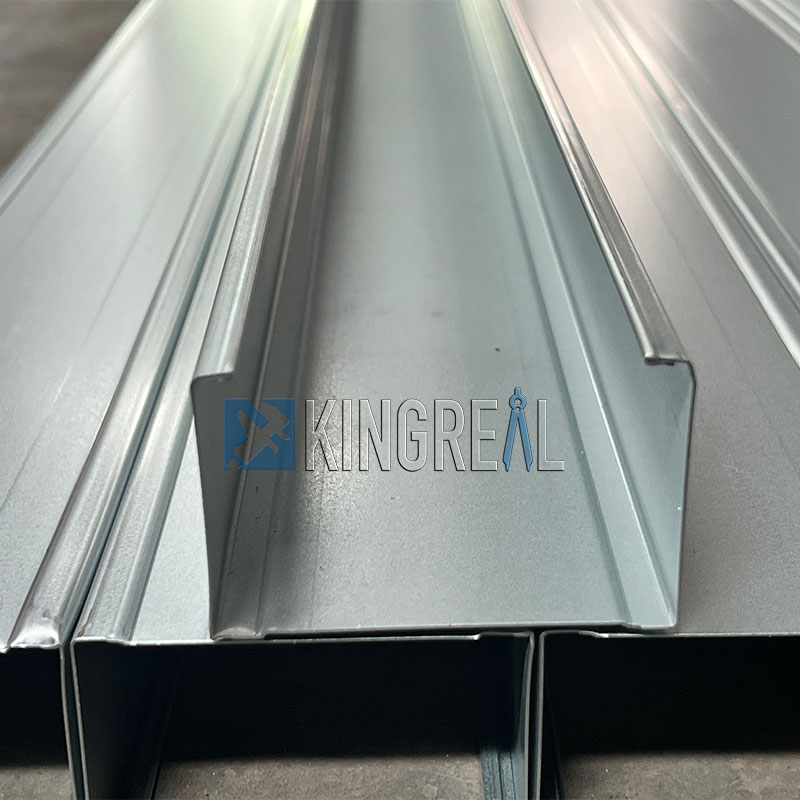

Stud & Track Manufactured With Drywall Profile Machine

KINGREAL drywall profile machines effectively create the two most widely used profiles on the market for drywall structures: studs and tracks. Studs are installed vertically and typically provide support in the main load-bearing structure of the wall, while tracks are installed above and below the studs to provide structural stability. Generally, the demand for studs is greater than that for tracks because studs are the main load-bearing components.

During manufacturing, the width of a stud is generally 73.5mm, while the width of a track is 75mm. Although there is a dimensional difference, this design ensures easier fit during installation. The dimensions of studs and tracks may vary depending on national regulations, but KINGREAL stud and track machines can be designed to meet the specific needs of each customer's country, ensuring full compliance with national building codes and industry standards.

Stud & Track Applications: Uses

KINGREAL drywall profile machine form the foundation for high-performance interior steel wall framing in construction projects worldwide. KINGREAL stud and track machines produce profiles that combine speed, reliability, and ease of use, ensuring simple, efficient, and high-quality installations every time. Whether it's standard partitions, non-load-bearing walls, or complex sound insulation and seismic structures, KINGREAL drywall profile machines can handle it all.

Advantages Of Stud & Track

Stud and track is increasingly favored by the construction industry due to its numerous advantages:

↘Versatility: Studs and tracks can be customized to meet different environmental needs, offering high adaptability.

↘Easy Installation: Compared to traditional building materials, drywall assembly time is shorter, resulting in higher construction efficiency.

↘Insulation and Soundproofing: When used in conjunction with insulation materials, it can significantly improve the environmental performance of buildings. Due to their lightweight, cost-effectiveness, and adaptability to modern design requirements, drywall profiles, including stud and track profiles, have become one of the most widely used solutions in building and finishing projects. They not only provide reliable structural support but also significantly improve construction flexibility and efficiency.

For more information about the drywall profile machine, please feel free to contact KINGREAL.