Difference Between Slitting And Cutting Machine

2025-10-31 11:25"In the metalworking industry, coil slitting machines and cut to length lines are two indispensable coil processing equipment. They each play different roles and meet different processing needs. This article will delve into the definitions, key differences, respective advantages, and innovations of coil slitting machines and cut to length lines to help you better understand the functions and applications of these two types of equipment."

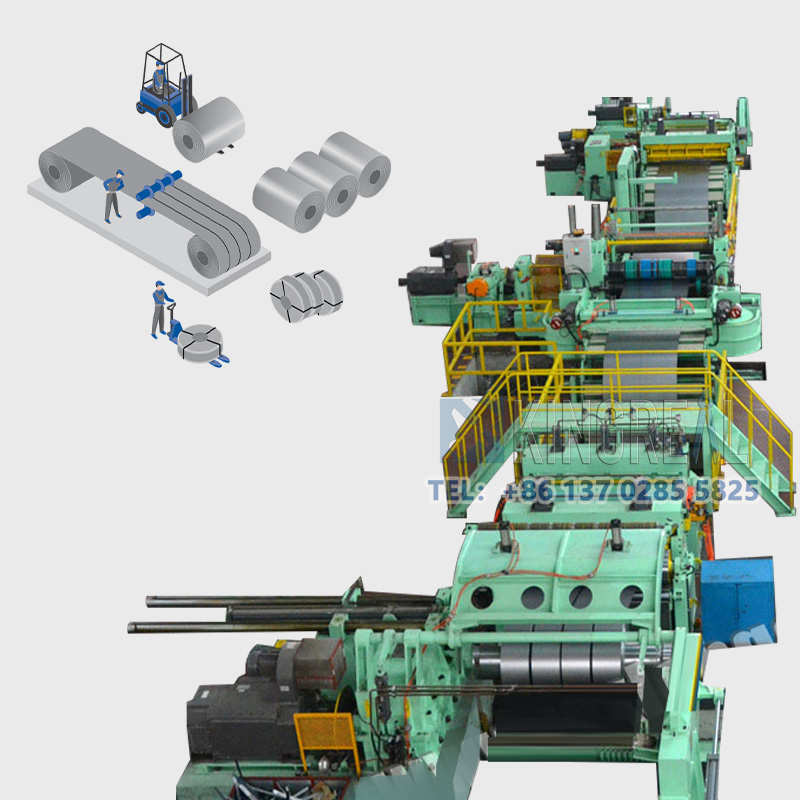

What is a Coil Slitting Machine?

A coil slitting machine is a device that cuts wide metal coils into narrow strips. Usually consisting of several essential elements, the slitting process is the longitudinal cutting of the metal coil normally including a decoiler, a slitter, and a recoiler. Material is fed into the slitter, where revolving knives perfectly cut the coil into the necessary narrow strips during slitting. These small strips are coiled for more handling once cut.

Especially in fields where material must be ready for further processing like roll forming, stamping, or tube construction, coil slitting machines are very common in many businesses. High-precision cutting by coil slitting machine guarantees correct material cutting to the necessary width, hence much boosting manufacturing effectiveness.

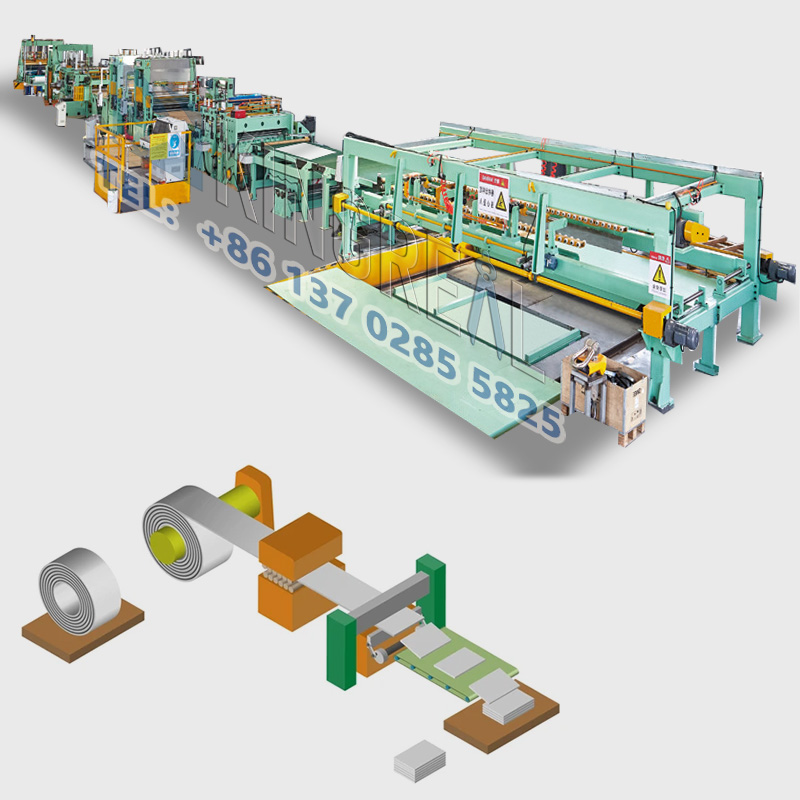

What is a Cut to Length Line?

A cut to length line is a device used to cut metal materials into specific lengths or shapes. Its working process typically involves unrolling the material, flattening it, and then cutting it to the required length. Depending on the material and the required precision, cut to length lines can be equipped with different shearing systems, such as fly shearing, rotary shearing, swing shearing, and fixed shearing.

Especially in construction, automotive manufacture, and appliance production, cut to length lines abound in several sectors. Cut to length lines cut to make sure the material's measurements exactly correspond with its desired application help to produce high-quality finished goods meeting market demands.

Key Differences Between Coil Slitting Machine and Cut to Length Line

While both coil slitting machines and cut to length lines are metalworking equipment, they differ significantly in several aspects:

Aspect | Coil Slitting Machine | Cut to Length Line |

| Purpose | Reduce roll width on longitudinal axis | Cut to shape/length in cross-direction or custom profiles |

Direction of cutting | Lengthwise along roll | Crosswise or multi-axis |

End products | Narrow rolls ready for further roll-feed use | Sheets, custom shapes, parts |

Rewinding | Yes – always rewinds strips into rolls | Typically no rewinding—finished parts removed after cut |

| Speed | Up to 230m/min | Up to 80m/min |

Advantages of Coil Slitting Machine and Cut to Length Line

Advantages of Coil Slitting Machine:

1)High-Speed Processing: Enables processing wide rolls into narrow strips at high speeds, improving production efficiency.

2)Precise Slitting: Ensures materials are slit precisely, minimizing material waste.

3)Versatile Processing: Handles various materials and thicknesses, adapting to different production needs.

Advantages of Cut to Length Line:

1)Precision Cutting: Capable of precisely cutting materials to specific lengths, meeting high-precision requirements.

2)Flexibility: Can cut sheet metal into specific shapes, adapting to different processing needs.

3)Wide Applicability: Can flexibly cut various materials, including aluminum, iron, stainless steel, etc., meeting the needs of multiple industries.

Innovation in Coil Slitting Machine and Cut to Length Line

With technological advancements, coil slitting machines and cut to length lines are constantly innovating to adapt to market demands. For example:

Innovations of Coil Slitting Machine:

-Light Duty Slitting Machine: Capable of handling 0.2-3mm thin sheet materials, suitable for lightweight products.

-Medium Duty Slitting Machine: Designed specifically for handling 3-6mm medium-thick plates, meeting a wider range of applications.

-Heavy Duty Slitting Machine: Capable of handling 6-16mm thick sheet materials, suitable for heavy-duty processing needs.

Customized Designs: A variety of customized coil slitting machines are available, such as belt tension slitting machine and dual slitter head slitting machine.

Innovation of Cut to Length Line :

-Light Duty Cut to Length Line: Suitable for handling 0.3-3mm lightweight materials, flexibly addressing different cutting requirements.

-Medium Duty Cut to Length Line: Capable of handling materials from 0.3-6mm thick, meeting the processing needs of medium to heavy plates.

-Heavy Duty Cut to Length Line: Designed for 6-20mm thick plates, suitable for heavy-duty processing.

-Equipped with Value-Added Equipment: Equipping the cut to length line with double levelers, double stackers, and laminating devices enhances its overall performance and processing efficiency.

This article demonstrates the significant differences between coil slitting machines and cut to length lines in terms of function, application, and advantages. While cut to length lines concentrate on material cutting, coil slitting machines cut broad rolls into small strips appropriate for productive settings. often used across many sectors into particular lengths and forms.Knowing these variations will guide your equipment selection based on knowledge. KINGREAL can supply you with the greatest options whether you decide on an effective coil slitting machine or a perfect cut to length line. Continue to follow KINGREAL articles for more practical information!

This series of articles is produced by KINGREAL, a manufacturer of coil processing equipment with over 20 years of experience, dedicated to providing high-quality machines and satisfactory service to customers worldwide. KINGREAL offer a wide range of customized, designed, and manufactured high-quality coil slitting machine and cut to length line solutions for companies in the sheet metal, construction, and manufacturing industries, ensuring that KINGREAL customers' production needs are met.