How does a gutter making machine work?

2025-06-16 12:00| KINGREAL specializes in the manufacture of gutter making machines and is a professional gutter roll forming machine manufacturer and seller. The gutter roll forming machines provided by KINGREAL to customers are custom-made machines, made of the highest quality materials, and designed to provide years of reliable service. If you want to know more about gutter making machines, this article is for you! I hope that through this article, you can learn some useful information related to gutter roll forming machines. |  |

Working Steps of Gutter Making Machines

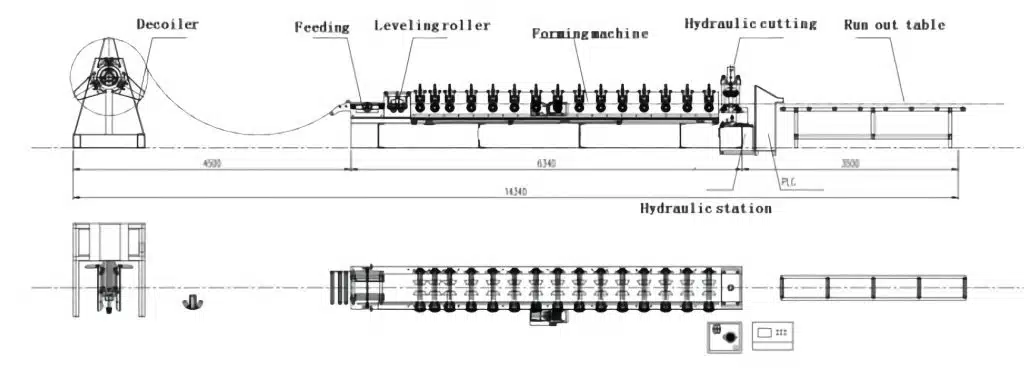

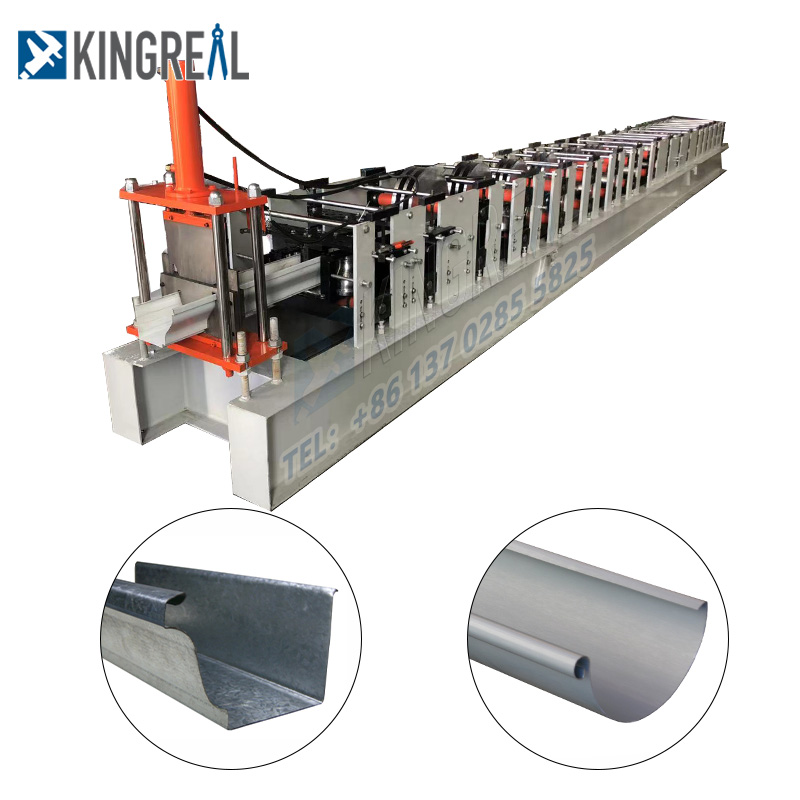

| The working principle of the gutter making machine is to load a roll of material (such as metal sheet or aluminum sheet) onto the decoiler of the gutter roll forming machine. After the decoiler unwinds the metal coil, it will feed the material into the roll forming machine, which forms the gutter under light pressure through a series of rollers. After reaching the required length, a device called a shearing station is used to make precise and clean cuts to the finished product. |  |

Detailed Steps to Operate the Gutter Making Machine

1. Simulation and operation of safety devices

During the installation stage of the gutter roll forming machine, it needs to be placed on a work platform that has been calibrated with a level to ensure that the main body of the gutter making machine remains vertical to the ground to avoid resonance or accuracy deviation caused by unstable foundation. Subsequently, the emergency stop button, photoelectric sensor, mechanical interlocking device and other safety components should be systematically tested, and their response speed and reliability should be verified through simulated trigger tests.

Finally, the voltage fluctuation range, grounding resistance value and cable insulation level of the power supply system should be checked according to the gutter roll forming machine nameplate parameters, and professional testing instruments should be used to confirm that the three-phase balance and interface waterproof performance meet the standards.

2. Material preparation stage

You need to load the appropriate metal coil (aluminum, steel or copper) into the machine and ensure that it is firmly positioned. In the material preparation stage, select aluminum, steel or copper metal coils according to the processing requirements. Place the steel coil on the decoiler for unwinding, and accurately load the steel strip into the feed port of the gutter making machine.

Double fixation by the clamping device and the positioning guide ensures that the material axis is completely consistent with the processing direction.

3. Normal operation of the gutter roll forming machine

Normal operation of the gutter making machine: When starting the gutter roll forming machine, please turn on the power and ensure that all components are operating normally. Ensure that the metal coil gradually passes through the gutter making machine during the advancement process to shape the gutter contour.

When starting the gutter roll forming machine, press the power switch to turn on the equipment and observe whether the indicator lights and instrument parameters on the control panel are normal. After the system self-check is completed, the metal coil is slowly guided to the feed port and gradually fed into the forming area through the guide wheel system. During the advancement process, it is necessary to maintain a uniform speed so that the coil goes through leveling, rolling forming, biting and other processes in turn, and gradually forms into the preset three-dimensional contour of the gutter.

During the operation, it is necessary to continue to pay attention to the operating status of each transmission component, and adjust the roller gap and traction speed in time to ensure that the material is flat and without deviation.

4. Cutting and receiving

When the gutter is processed to the required length, the intelligent cutting system of the gutter making machine will automatically start, and high-precision signal positioning will be used to achieve precise cutting to ensure that the end surface is flat and burr-free. Of course, if you want to improve the automation level of the gutter roll forming machine, you can also choose an intelligent stacking device.

Advantages of Gutter Roll Forming Machine

(1)Expertise and experience for gutter making machine: The KINGREAL team has been taught to manufacture the newest model of the gutter roll forming machine, thereby giving consumers customized solutions for different kinds of homes. (2)To satisfy the varied demands and tastes of our clients, KINGREAL gutter roll forming machine are sometimes designed for compatibility with a large spectrum of metal materials including aluminum, steel, and copper. (3)Customized gutter making machine: KINGREAL gutter making machine are custom made from the finished product plans supplied by our clients to guarantee that the gutter shape and size exactly fit the customer's home. (4)Accessories for gutter making machine: KINGREAL can also offer customers some extras to improve the functioning of their flawless gutter systems. |  |

Key Features to Consider When Choosing a Gutter Making Machine

1

Material Suitability

Different materials including aluminum, copper, or steel match with various gutter making machine. The materials you expect to use most often should be taken into account while choosing a gutter roll forming machine. For instance, if you mostly deal in copper, purchasing an aluminum-intended gutter making machine would not be logical. Hence, one of your highest priorities should be to verify the material compatibility of the gutter making machine.

2

Weight and Portability

While some gutter making machine is fixed and mounted in a workshop or factory, others are made to be portable and practical for on-site gutter manufacturing. You might favor one over the other depending on your particular working conditions and demands.

3

Form of Output

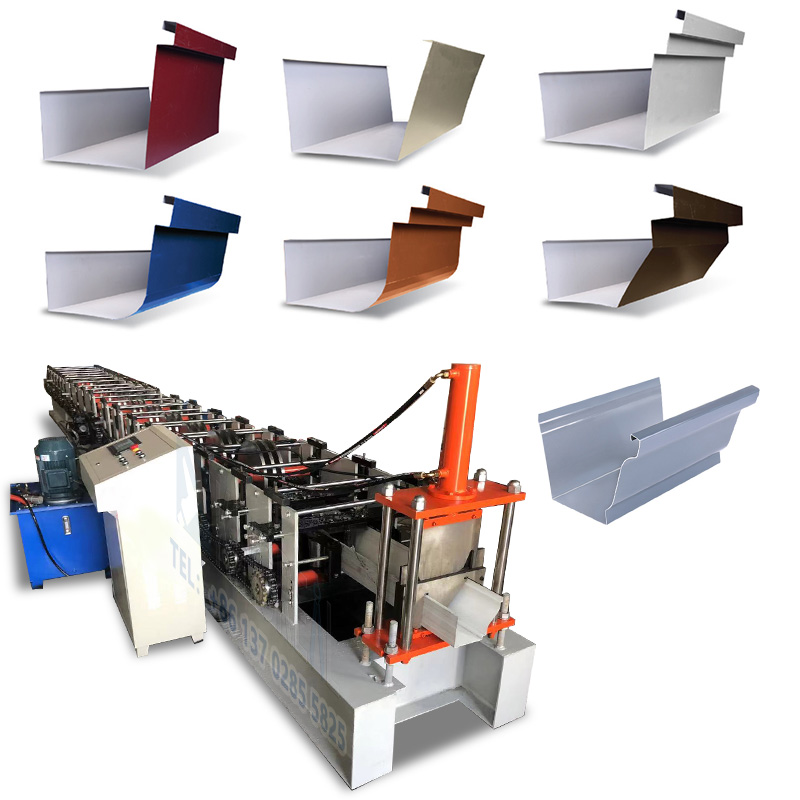

As previously stated, various shapes of gutters—K-shaped, half-round, or box-shaped—can be made on various gutter roll forming machine. Make sure the gutter making machine you pick can generate the completed form suitable for your or your clients' needs. This is particularly vital for companies that provide several gutter types.

4

Reputation of the manufacturer

Finally but not least, one must take into account the reputation of the producer. Usually, trustworthy and highly regarded companies guarantee product quality and longevity. It is better to pick a respectable brand that might be somewhat more expensive but guarantees durability and good customer service rather than saving upfront costs by selecting a lesser known brand that could lead to higher costs later owing to poor quality or lack of technical help and supplies.

Often Asked Questions About Gutter Construction Machines

What is a Gutter Roll Forming Machine?

Important components that direct rainwater away from the foundation and off the roof of a structure, gutters are manufactured with equipment called as gutter making machine.

Which gutter making machine is available?

Each built to create a particular kind of gutter, there are many different types of gutter making machine. Most often are K-type gutter roll forming machines, half-round gutter roll forming machines, fascia gutter making machines, and box gutter making machines.

How to maintain a gutter roll forming machine?

Keeping a gutter roll forming machine depends on regular cleaning and lubrication. Furthermore, always adhere to suggested safety guidelines while operating/maintaining the gutter making machine