Why is double layer roofing sheet machine so important?

2025-06-07 12:00

In the modern construction industry, metal roof tiles are increasingly used, and almost every building needs roof tiles to protect its structure while providing an aesthetically pleasing appearance. Roof tiles are not only effective in waterproofing and heat insulation, but also enhance the overall beauty of the building. Therefore, roof tile production equipment, metal roofing machines, have become particularly important. Their main function is to efficiently produce various types of roof tiles to meet the market demand for different roof tiles.

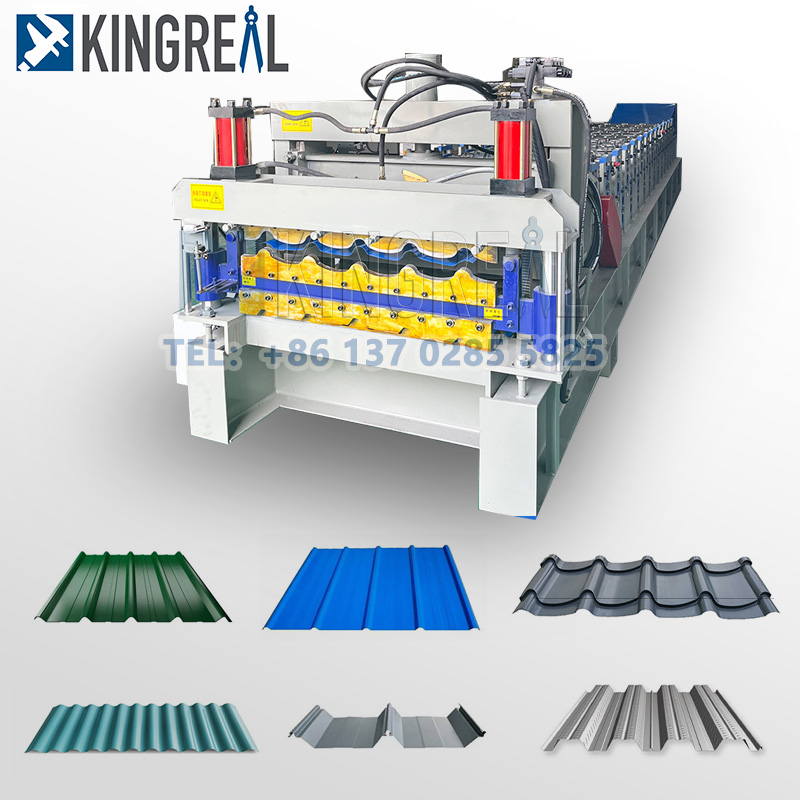

With the continuous development of the construction industry, the market demand for roof tiles has become more and more diversified. Many merchants selling finished roof tiles are not satisfied with a single type of product, but hope to be able to provide a variety of different types of roof tiles to meet the personalized needs of customers. Against this background, double layer roll forming machines came into being and became an ideal solution for producing diversified roof tiles.

1. Background and Importance of Double Layer Roofing Sheet Machines

1.1 Diversity of market demand Due to the different designs and customer needs of each construction project, the market's requirements for the types and styles of roof tiles are increasing. Traditional single-layer roof tile machines can often only produce one type of tile, which limits the production flexibility of merchants. The emergence of double layer roll forming machines enables merchants to produce two different types of roof tiles on one device, greatly improving production efficiency and flexibility.

1.2 Improvement of production efficiency The double layer roofing sheet machine can not only flexibly adjust the production line according to market demand, but also switch different types of tile production in a short time. This efficient production method enables merchants to respond quickly when facing diversified market demands, thereby improving market competitiveness. |  |

2. Advantages of Double Layer Roll Forming Machines

2.1 Available metal materials The double layer roofing sheet machine can handle a variety of metal materials, including common galvanized steel, aluminized steel, pre-coated galvanized steel, pre-coated aluminized steel, aluminum alloy, etc. This flexibility allows customers to choose suitable materials for production according to project requirements to meet the design requirements of different buildings. If customers have special material requirements, they can also consult with KINGREAL to obtain customized solutions.

2.2 Thickness of processed metal materials The double layer roll forming machine can usually handle metal materials with a thickness of 0.3mm to 0.8mm. However, the specific thickness range will be adjusted according to the customer's drawings and actual production needs. Therefore, this parameter is for reference only, and customers should confirm with suppliers in actual use to ensure that the double layer roofing sheet machine can meet specific production requirements.

2.3 Free combination of two types of roof tiles The biggest advantage of the double layer roll forming machine is that it can freely combine two different types of roof tiles according to demand. This means that merchants can produce two different styles of tiles on one double layer roofing sheet machine, avoiding the high cost of purchasing two devices. This flexibility not only saves money, but also reduces the complexity of equipment maintenance and operation. |  |

3. Importance of Double Layer Roll Forming Machines in Practical Applications

3.1 Adapt to market changes With the continuous changes and development of the construction industry, the market demand for roof tiles is also evolving. Double layer roofing sheet machines enable manufacturers to quickly adapt to these changes and adjust production strategies in time to meet the latest needs of customers. This flexibility enables merchants to remain invincible in the highly competitive market.

3.2 Reduce production costs With the double layer roll forming machine, merchants can complete the production of multiple products on one device, significantly reducing equipment investment and operating costs. Compared with purchasing multiple single-function roof tile machines, the double layer roofing sheet machine has a higher return on investment and can pay back in a shorter time.

3.3 Improve product quality The double layer roll forming machine is equipped with an advanced control system that can ensure high precision and consistency in the production process. This efficient production method not only improves production efficiency, but also ensures the quality of each roof tile, reducing rework and losses caused by quality problems. |  |

4. Market Prospects of Double Layer Roofing Sheet Machines

4.1

Continued growth in the construction industry

With the continued growth of the global construction industry, especially in emerging markets such as South Africa, the demand for roof tiles will continue to increase. With its high efficiency and flexibility, double layer roll forming machines will surely occupy an important position in the future market.

4.2

Promotion of green buildings

With the increase in environmental awareness, green buildings have gradually become a development trend in the construction industry. Double layer roll forming machines can be produced using renewable materials, which meets the environmental protection requirements of modern buildings. This advantage makes double layer roofing sheet machines more attractive in future market competition.

4.3

Technological innovation and market expansion

With the continuous advancement of science and technology, the technology of double layer roll forming machines is also constantly updated. Intelligent and automated production processes will further improve production efficiency and product quality. At the same time, as the market demand for diversified products increases, the market prospects of double layer roofing sheet machines will be broader.

If you have any questions about the double layer roll forming machine or need further information, please feel free to contact KINGREAL. KINGREAL professional team will provide you with high-quality products and services to help your business development. Choosing a double layer roofing sheet machine, you will be able to occupy a place in the future construction market and achieve greater success.