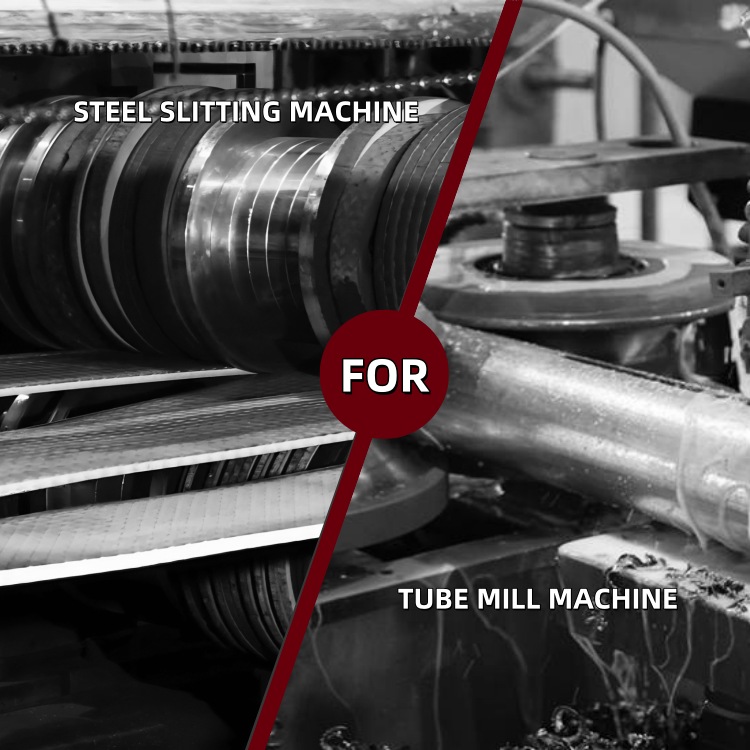

Steel Slitting Line For Tube Mill Machine

2025-10-16 12:00Steel slitting lines and tube mill machines are both essential equipment in modern industry. Their widespread demand in the steel processing sector leads to a close relationship between them. This article will provide a detailed introduction to the working principles, features, and collaborative relationship between steel slitting line and tube mill machine, helping you better understand their importance in industrial production.

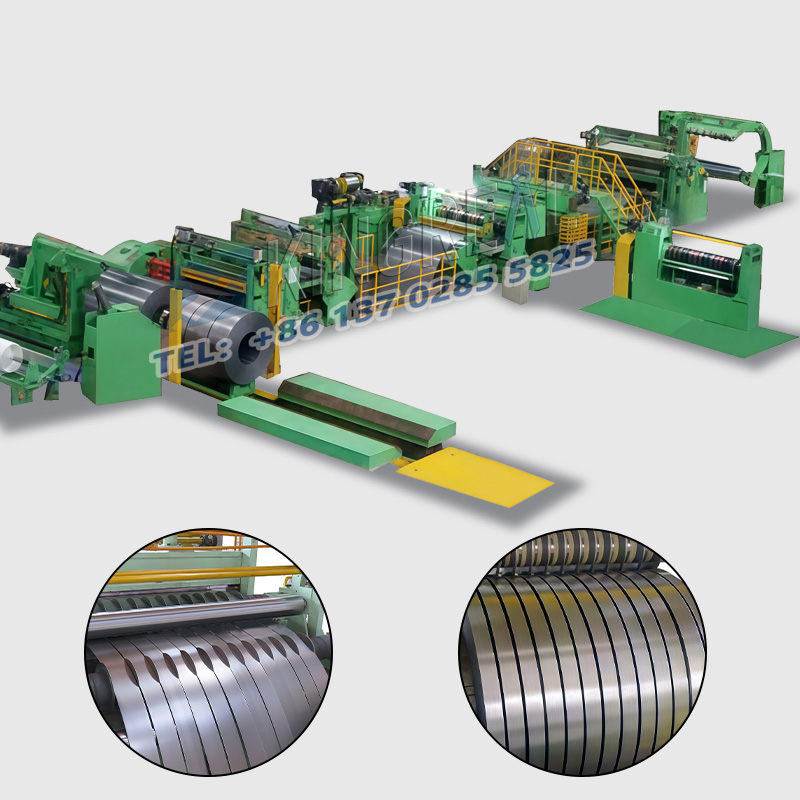

Introduction to Steel Slitting Machine

Steel slitting lines are used to slit large metal coils into narrow strips of customer-specific widths. They are widely used in processing a variety of materials, including aluminum, steel, stainless steel, copper, and PPGI. Steel slitting lines use a series of precise mechanical devices to separate wide metal coils into multiple narrow strips for subsequent processing.

●Features of KINGREAL STEEL Slitting Machine: -Multi-Material Processing Capability: KINGREAL steel slitting lines can process a variety of metal materials, including aluminum, steel, stainless steel, and copper, to meet the needs of diverse customers. -Highly Efficient Production Capacity: This steel slitting line can simultaneously slit up to 40 narrow strips, significantly improving production efficiency. -Fast Production Speed: The steel slitting line can reach a maximum speed of 230m/min, saving customers time and costs. -Wide Thickness Compatibility: The steel slitting line can process metal coils with thicknesses ranging from 0.2 to 16 mm, demonstrating its wide adaptability. These features provide high-quality raw materials for the subsequent tube mill machine, ensuring an efficient and stable production process. |  |

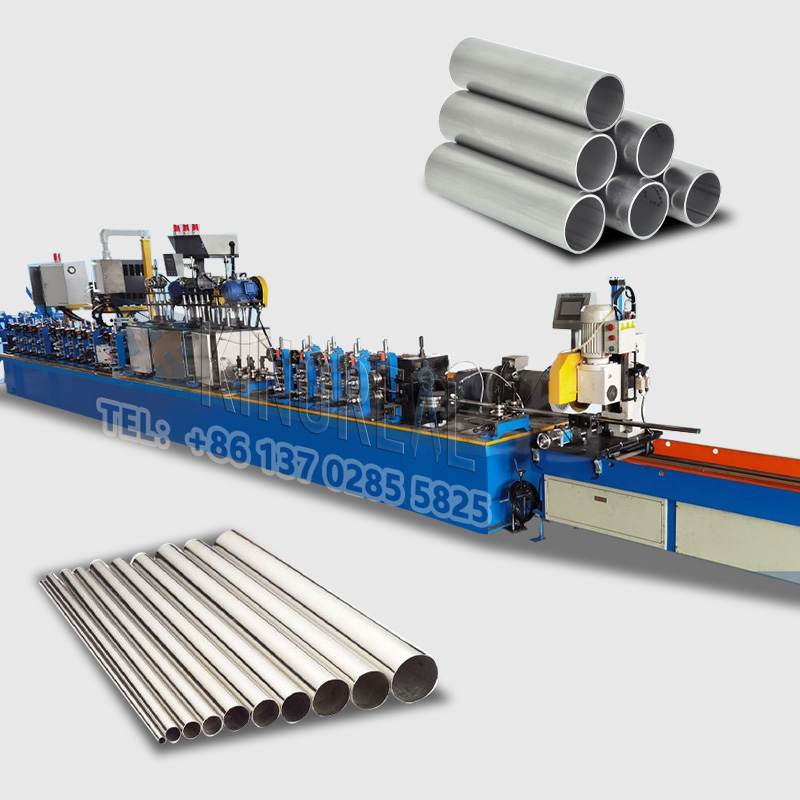

Introduction to Tube Mill Machine

Tube mill machines process narrow metal strips into square or round tubes. They are widely used in a variety of fields, including aerospace, medical, automotive, construction, and chemical engineering. Steel tubes produced by tube mill machines are even used in some dance performances.

●Features of KINGREAL Tube Mill Machine: -High Level of Automation: The tube mill machine requires only three people to operate, responsible for shearing, butt welding, high-frequency welding, and packaging, significantly reducing labor costs. -Sizing: During this process, the tube mill machine converts round tubes into square tubes or adjusts round tubes to a more round shape, ensuring that the final product meets customer specifications. -Double-blade scraping technology: After high-frequency welding, a double-blade scraping device is used to remove excess material and smooth the weld seam to ensure weld quality. -Grinding process: The grinding step is performed before water cooling to prevent cracking and provide insulation. -Flying saw cold cutting: Compared with hot cutting, flying saw cold cutting is safer, more efficient, and saves energy. -Flexible production specifications: By changing the mold, the tube mill machine can produce pipes of different specifications and shapes to meet the needs of different markets. The complex process flow of the tube mill machine ensures high-quality end products and meets the steel pipe needs of various industries. |  |

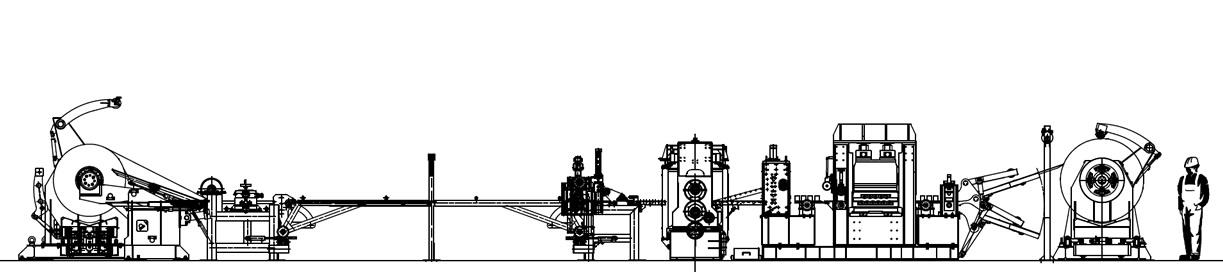

Relationship Between Steel Slitting Machine and Tube Mill Machine

The steel slitting line and the tube mill machine have a very close relationship. The narrow strips produced by the steel slitting line are the direct raw material for the tube mill machine. The following is a detailed collaborative process:

-Metal Coil Preparation: First, the metal coil is processed by the steel slitting line's main components, including the hydraulic decoiler, pre-slitting devices, and precision slitting devices.

-Strip Production and Recoiling: After processing by the steel slitting line, the metal coil is slit into strips of customer-specific specifications and then recoiled, ready for use in the tube mill machine.

-Strip Uncoiling: These metal strips are placed in the tube mill machine's decoiler for uncoiling, preparing them for the tube making process.

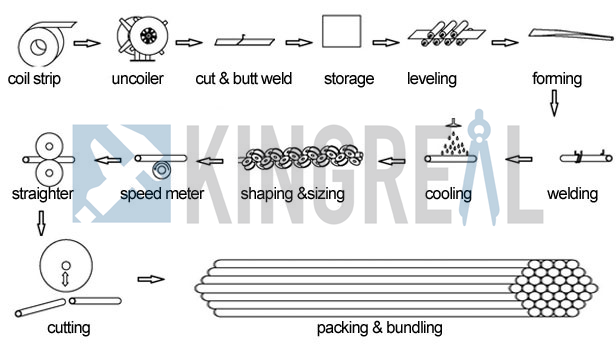

-Tube Manufacturing Process: Within the tube mill machine, narrow strips pass through a series of precision components, including the Steel Strip Leveler, Shear and End Welder, Accumulator, Forming Section, High-Frequency Welding Device, Sizing Section, Flying Saw, and Packaging Machine, before being transformed into the customer's desired square or round tube.

-Welding and Cooling: During the welding process, the tube mill machine heats and melts the edges of the strips at high temperatures, forming a high-strength weld seam. After cooling, the seam is deburred, longitudinally high-frequency welded, and finally cut into the desired length of steel tube.

Through this series of processing steps, the steel slitting lines and tube mill machines work together to form an efficient production chain, ensuring the quality and efficiency of steel tube production.

As indispensable equipment in modern industry, the close relationship between the steel slitting line and tube mill machines not only improves production efficiency but also ensures product quality. Thanks to the efficient slitting capabilities of steel slitting lines, tube mill machines are able to produce high-quality raw materials, playing a vital role in various industries. Whether in construction, automotive, medical, or other sectors, the collaboration between steel slitting line and tube mill machines is an indispensable part of modern manufacturing. With the continuous advancement of technology, the application areas of these two types of equipment will expand in the future, bringing more possibilities and benefits to industrial production. For more information on tube mill machine and steel slitting lines, please feel free to contact KINGREAL!