What is C Truss Making Machine?

2025-10-14 12:00The c truss making machine is a specialized machine designed specifically for the construction industry, primarily used to produce c trusses. The arrival of this c truss roll forming machine has greatly enhanced the accuracy and efficiency of partition wall production, therefore helping the building sector to more closely match market demand. Important stability and support in building projects come from c trusses. Their usage is increasing especially in contemporary design.

What is C Truss Making Machine?

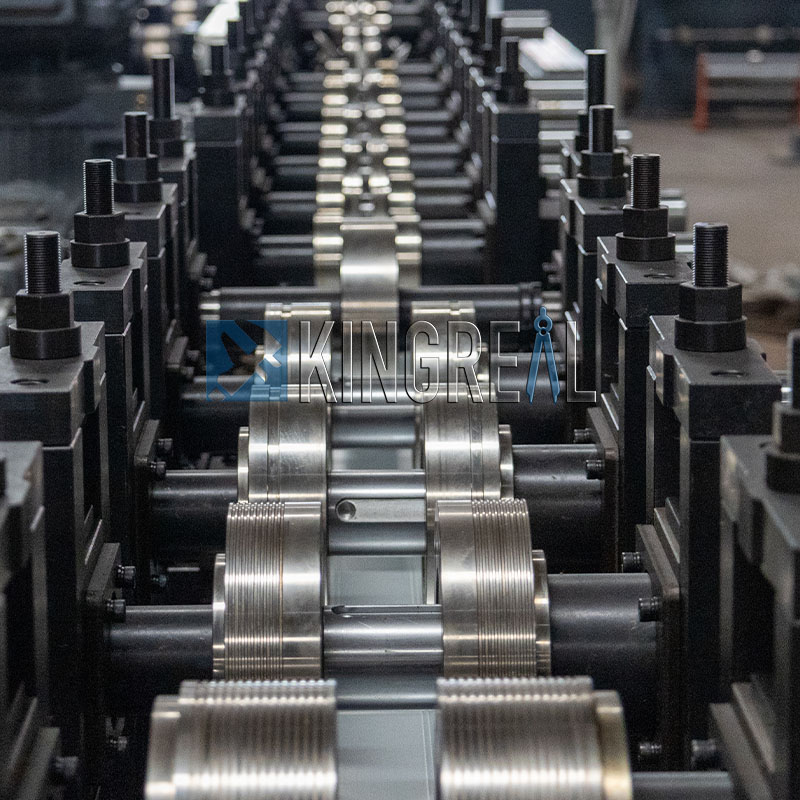

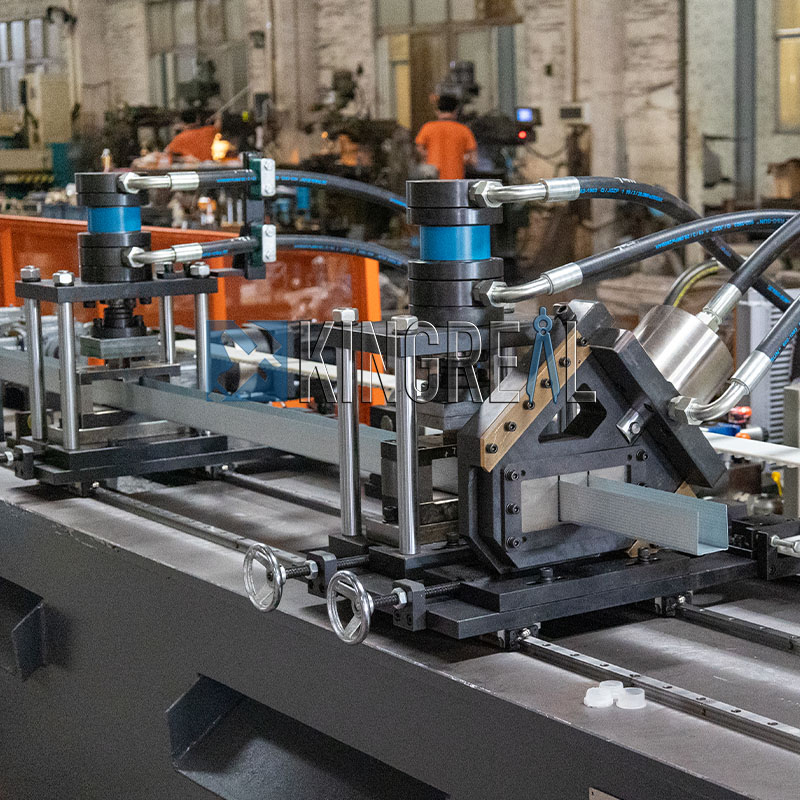

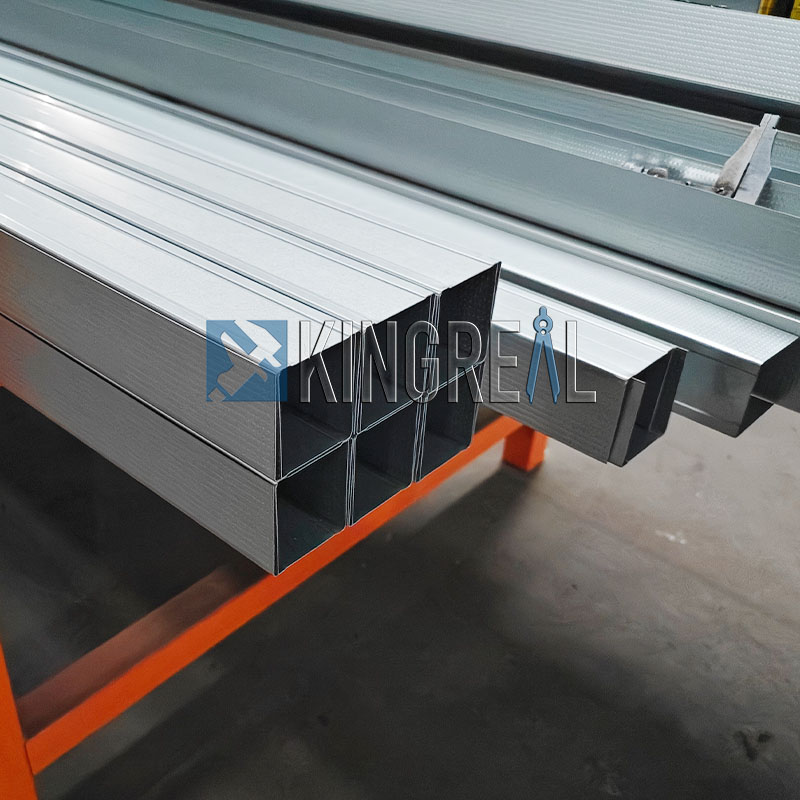

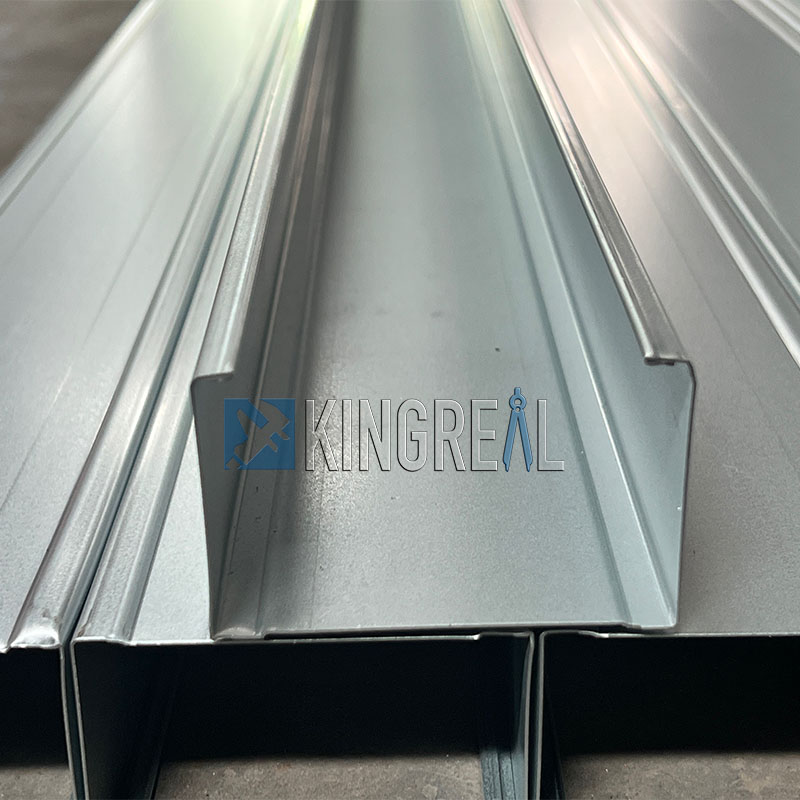

A c truss making machine is a specialized roll forming machine used to make c trusses. This c truss roll forming machine typically uses galvanized sheet metal as its raw material, bending and forming the metal coil into the desired c-shaped profile using a continuous process. The steel coil is fed into the c truss making machine for uncoiling beginning with the process. Smooth unwinding of the metal coil is guaranteed by the decoiler, therefore ready for next forming. Then the coil goes through a battery of precise rollers that progressively curves it into the intended c-shaped profile. Cutting the metal to the needed length and creating any needed holes on a punching station.

Common uses for c trusses in the construction sector are structural support for partition wall systems. Lightweight, great strength, and simple installation make the c truss generated by the c truss making machine rather popular. The addition of this device by KINGREAL allows customers to create significant amounts of c truss precisely and effectively to meet the demands of the building sector.

Features of C Truss

The c truss roll forming machine is primarily used in the construction industry. The c truss it produces primarily serves as wall frames, providing support for exterior and interior walls in a variety of commercial and residential buildings. The c truss produced by this c truss making machine offers the following advantages:

-Lightweight: The c truss's relatively light weight makes transportation and installation easier, reducing labor costs.

-High Strength: Made from high-strength galvanized steel, the c truss exhibits excellent load-bearing capacity, meeting the requirements of modern construction.

-Easy Installation: The c truss' design allows for quick installation during construction, reducing construction time.

-Versatility: The c truss not only provides support within partition systems but also provides sound insulation, moisture resistance, and fire resistance, further enhancing the overall performance of a building.

As a result, the c truss roll forming machine has gained widespread popularity in the market and has become the preferred equipment of many construction companies.

Different C Truss Making Machine Manufacturing Options

KINGREAL specializes in providing customized c truss making machine solutions based on customer needs. These solutions not only take into account the customer's specific drawings but also incorporate the policy requirements and climatic conditions of the customer's country, ensuring the c truss roll forming machine design meets actual production needs.

1. C truss making machine equipped with auto packaging unit

To maximize efficiency and automation throughout the entire production process, KINGREAL has equipped the c truss roll forming machine with an auto packaging machine. The packaging machine bundles and stacks the profiles, reducing labor costs while ensuring product quality and efficiency. This feature is particularly important for customers with large-scale production.

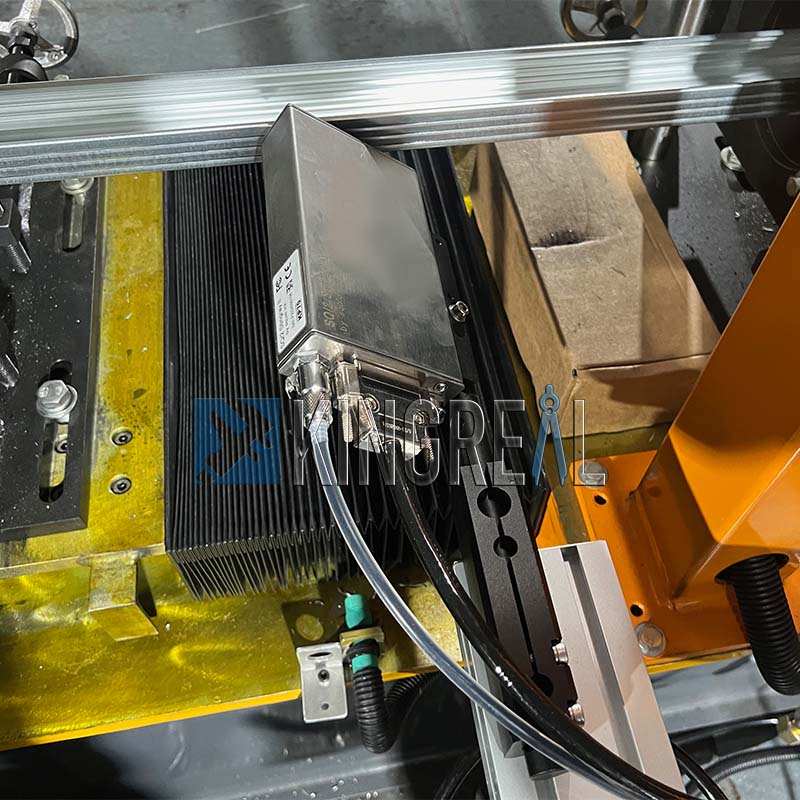

2. C truss making machine equipped with an inkjet device

KINGREAL has also equipped the c truss roll forming machine with an inkjet device. During the forming process, the c truss making machine can print the customer's logo or other desired text on the finished product. This not only enhances the competitiveness of the finished product but also facilitates brand promotion.

3. Light duty & heavy duty c truss making machine

KINGREAL provides both lightweight and robust machinery to better match consumers with different manufacturing volumes and needs. While the heavy-duty c truss roll forming machine can handle metal coils with a thickness of 0.35–0.9mm at a production speed of 50–60 m/minute, the light duty c truss making machine processing metal coils with a thickness of 0.8–1.2 mm at a manufacturing rate of 60–80 m/min is possible. KINGREAL has created a high-speed c truss roll forming machine capable of running at 120 m/min for customers looking for even greater efficiency.

4. Customized c truss making machine solutions

Designed to satisfy the particular demands of every customer, KINGREAL also provides tailored c truss roll forming machine solutions. Whether it be c truss making machine size, manufacturing capacity, or the addition of additional functions, KINGREAL can customize the c truss making machine to the particular needs of the customer to make sure every c truss making machine meets their requirements. C truss roll forming machine is just right for their manufacturing setting.

Advantages of C Truss Making Machine

The main advantages of using a c truss making machine include:

-Efficient Production: The automated production process significantly improves production efficiency, enabling the production of large quantities of products in a short period of time.

-High Precision: The c truss roll forming machine's advanced design and precise control ensure that each c truss is of consistent size and shape, meeting the strict standards of the construction industry.

-Easy Operation: The c truss making machine's user-friendly interface allows workers to easily operate it after simple training, reducing labor costs.

-Sturdy Frame: Constructed of high-strength materials, the c truss roll forming machine offers excellent durability and can operate stably in high-intensity working environments.

-High Maintainability: The c truss making machine provided by KINGREAL is easy to maintain. Customers can ensure long-term stable operation through regular inspections and maintenance.

In contemporary construction manufacturing, the c truss roll forming machine is absolutely necessary. KINGREAL c truss making machine, with its effective manufacturing capacity and accuracy, reliability, and efficiency demand for c truss roll forming machine in the building industry, will help. Many building firms now see flexible customization choices as the best option. Through continuous innovation and technological advancement, KINGREAL will continue to be committed to providing customers with better quality c truss making machines and comprehensive services, helping customers to remain invincible in the highly competitive market. If you have further needs or questions about c truss roll forming machines, please feel free to contact KINGREAL.