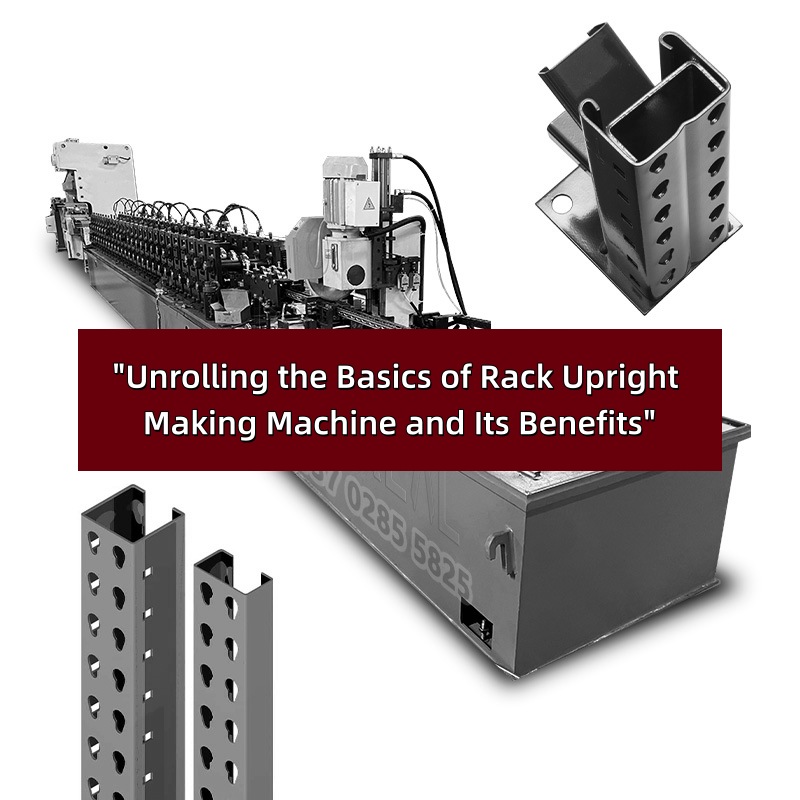

Unrolling the Basics of Rack Upright Making Machine and Its Benefits

2025-10-06 12:00Rack upright making machine uses galvanized or cold-rolled steel as raw material and form upright profiles into specific shapes and sizes through a series of steps. The forming process includes a decoiler, leveling machine, punching machine, main roll forming machine, cutting station, and discharge table. The upright rack roll forming machine operates by transforming metal coils into finished uprights through a series of precise steps. These uprights are widely used in racking systems to support various storage needs. A frequency converter controls motor speed, and a PLC system automatically controls length and quantity, enabling continuous, automated production.

KINGREAL rack upright making machines are specifically designed to produce a variety of uprights, including both light and heavy-duty ones. KINGREAL also offers shelf panel roll forming machine, box beam roll forming machine, step beam making machine, and slotted angle making machine, all of which are integral to pallet racking systems.

Workflow of Rack Upright Making Machine

Manual decoiler→leveling—>Mechanical Press Machine with Punch DIE→roll forming machine→shape cutting→output table

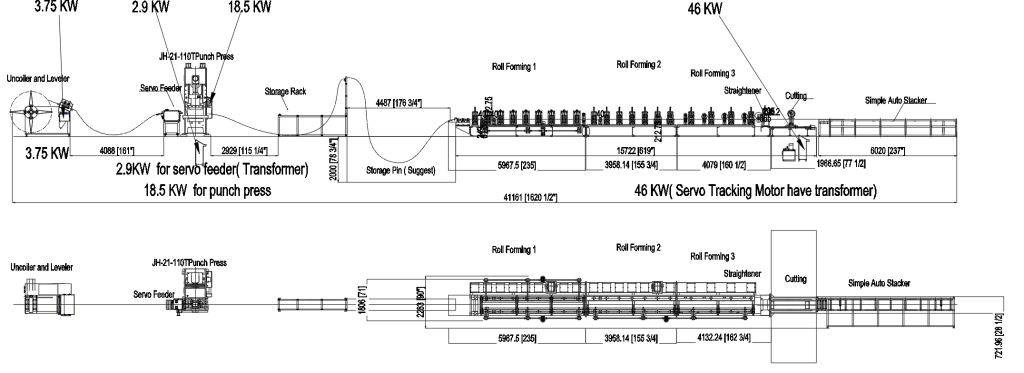

Parameters of Rack Upright Making Machine

| Suitable Raw Material | |

| Material | Galvanized |

| Thickness | 0.8-2.5mm |

| Coil width | According to products size |

| Yield Strength | 250-400Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | About 19 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 20m/min |

| Forming rollers material | Cr12 mould steel, with quenched treatment |

| Cutter material | Cr12 mould steel, with quenched treatment |

| Controlling system | Combined with: PLC, Touch Screen, Inverter, Encoder, etc |

| Electric Power requirement | Main motor power: 18.5kw Hydraulic unit motor power: 11kw |

| Electric voltage | According to customer’s requirement |

Features of Upright Rack Roll Forming Machine

1. Highly efficient rack upright making machine

The upright rack roll forming machine utilizes advanced CNC technology and an automated control system, enabling it to quickly and accurately form and cut uprights according to pre-set procedures and parameters. This high efficiency not only improves production efficiency but also significantly reduces labor costs, helping companies achieve a higher level of production automation. In actual production, the upright rack roll forming machine operates according to pre-set procedures and parameters. Through the PLC system, operators can easily set and adjust machine operating parameters such as forming speed, cutting length, and production quantity.

2. Highly precise upright rack roll forming machine

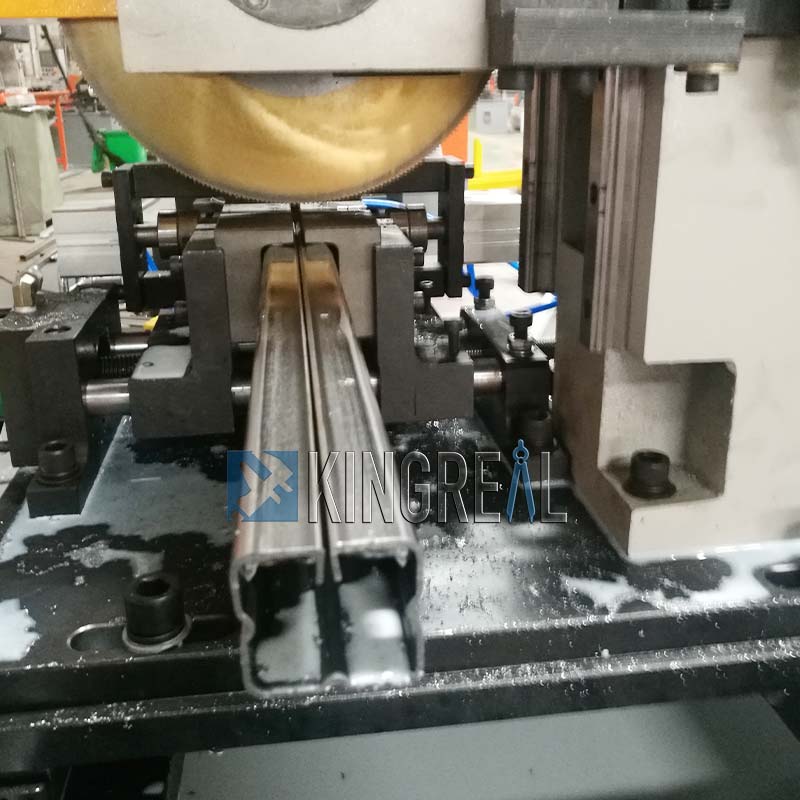

KINGREAL rack upright making machine ensures that each upright profile meets customer specifications for size and shape. High-precision forming rollers and cutting systems ensure product consistency and stability, meeting the demand for high-quality uprights in the racking industry.

KINGREAL upright rack roll forming machines are equipped with high-quality forming rollers and cutting systems. The precision-machined forming rollers ensure uniform pressure on the metal during the forming process, resulting in ideal forming results. The cutting system utilizes high-precision cutting tools, ensuring smooth cuts and minimizing burrs. This not only improves the finished product's appearance but also reduces the complexity of subsequent processing.

3. Highly stable rack upright making machine

KINGREAL upright rack roll forming machine utilizes high-strength materials and a robust structural design, ensuring stable performance even during long periods of continuous operation. During the rack upright making machine design process, KINGREAL engineers carefully considered the upright rack roll forming machine's robust foundation and rational layout, ensuring that all components function properly under intense operation.

Furthermore, the rack upright making machine's mechanical components undergo rigorous testing and screening to ensure they maintain optimal performance even in extreme environments such as high temperature and high humidity. This high stability not only improves production efficiency but also reduces the frequency of maintenance and repairs.

4. Highly flexible rack upright making machine

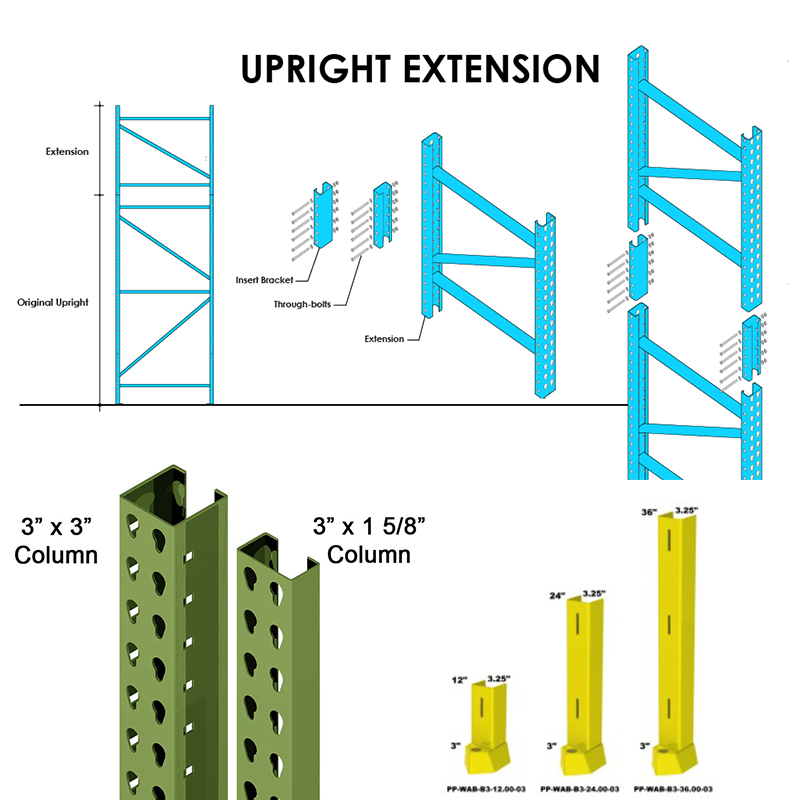

The upright rack roll forming machine's control system allows the operator to quickly adjust parameter settings to meet varying production needs without requiring lengthy machine downtime. For example, if a customer requires a upright of a different size, the operator simply enters the new dimension parameters on the touchscreen, and the upright rack roll forming machine instantly switches to the new production mode. Whether it's lightweight or heavy-duty columns, KINGREAL rack upright making machines can be customized to meet specific customer needs.

Applications of Upright Rack Roll Forming Machine

Uprights produced by upright rack roll forming machines are widely used in various fields, particularly in the warehousing and logistics industries. And KINGREAL upright rack roll forming machines can produce upright profiles in various shapes and sizes, such as rectangular, round, and special shapes, according to customer-specific requirements, to meet the needs of various shelf structures and designs.

KINGREAL Rack Upright Making Machine Design and Innovation

KINGREAL is continuously committed to technological innovation and product upgrades to meet market demands and the diverse needs of KINGREAL customers. KINGREAL engineers continuously refine the design and functionality of upright rack roll forming machines through market research and customer visits.

1. Customized rack upright making machine solutions

KINGREAL excels at providing customized upright rack roll forming machine solutions based on customer drawings and actual production needs. Whether it's light-duty or heavy-duty uprights, KINGREAL can customize a rack upright making machine to meet your specific requirements. Through these customized upright rack roll forming machine solutions, KINGREAL not only improves customers' production efficiency but also helps them gain a greater competitive advantage in the market.

2. Automation technology for rack upright making machine

In terms of automation technology, KINGREAL actively introduces advanced control systems, striving to provide customers with intelligently controlled and highly automated upright rack roll forming machines. The PLC control system and touchscreen interface allow operators to easily monitor and adjust the rack upright making machine's operating status.

3. Ongoing customer support for rack upright making machine

KINGREAL offers comprehensive after-sales technical support and maintenance services. After installing the upright rack roll forming machine for customers, KINGREAL team will continue to monitor its operation to ensure smooth production.

If you're interested in a rack upright making machine, please feel free to contact KINGREAL!