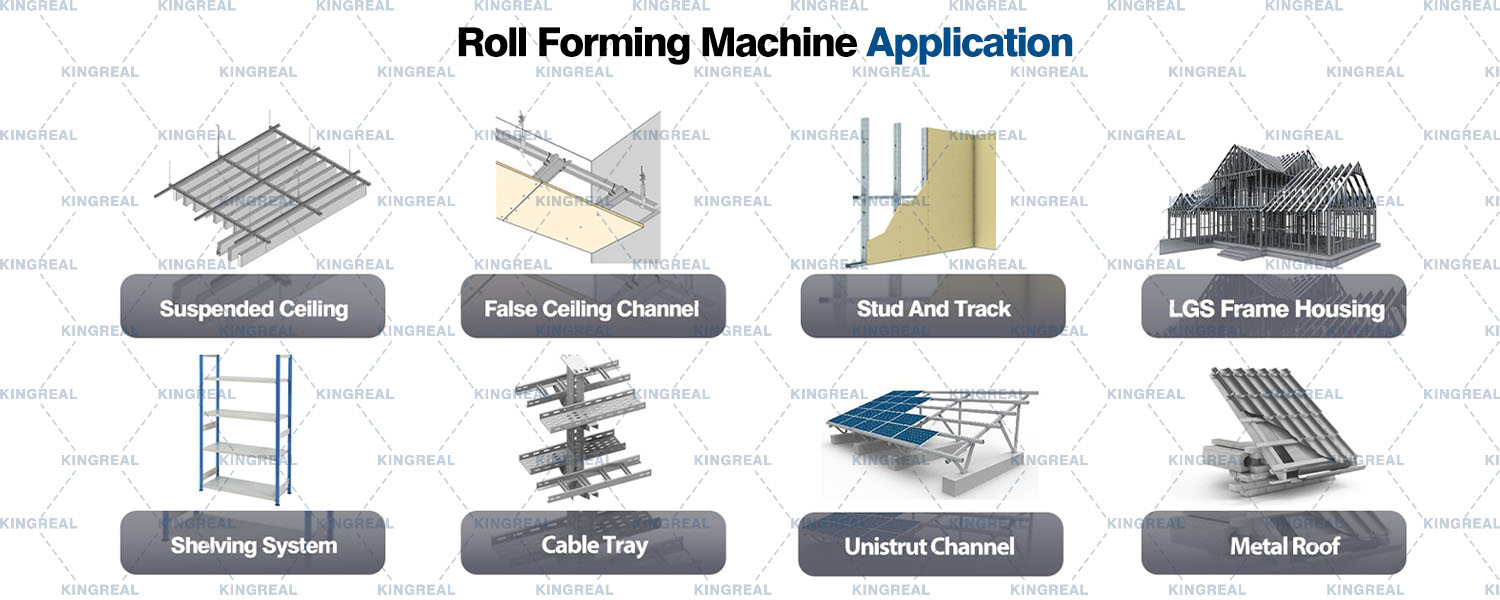

Application of Roll Forming Machines

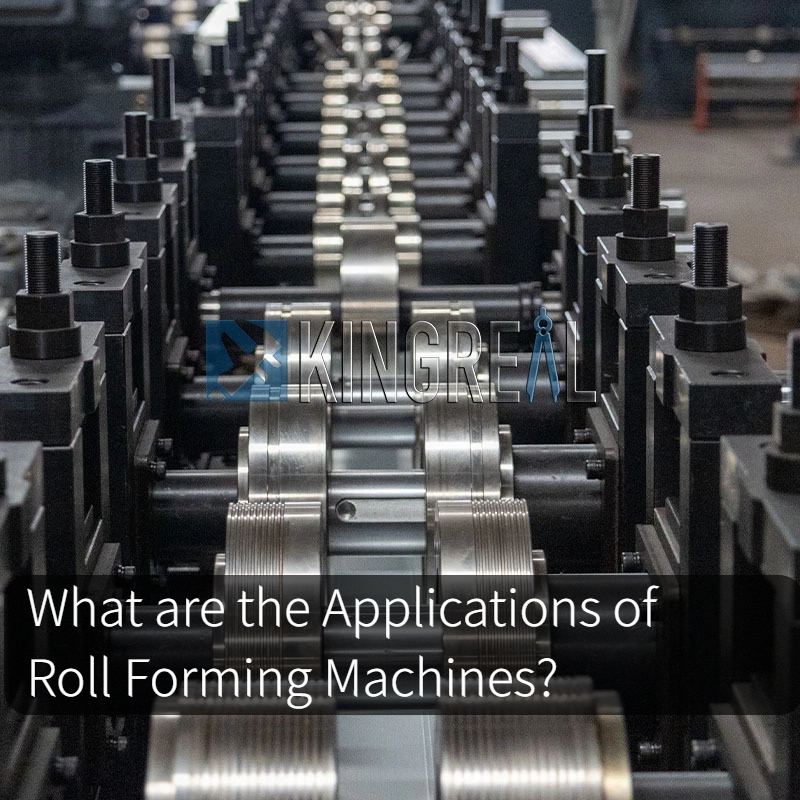

2025-10-02 12:00Roll forming machines play an indispensable role in modern manufacturing. As a professional roll forming machine manufacturer, KINGREAL is committed to providing a wide range of roll forming machines to meet the needs of various industries. Whether it's for suspended ceilings, housing, walls, photovoltaics, or shelving, KINGREAL has corresponding roll forming machine solutions. This article will detail the specific applications of KINGREAL roll forming machines in various fields.

● Roll Forming Machine in Suspended Ceiling System

Suspended ceilings come in a variety of types and sizes, but without exception, almost all are produced using roll forming machines. KINGREAL offers a variety of roll forming machines tailored to each customer's specific production needs, including baffle ceiling machine, open cell ceiling machine, and linear strip ceiling machine. These roll forming machines can produce different types of suspended ceilings tailored to customer needs and are widely used in various venues, including hotels, train stations, restaurants, and homes.

In addition, for gypsum ceiling installation, KINGREAL also offers hat channel machine, main channel making machine, and drywall wall angle profile machine, producing profiles that effectively support and stabilize gypsum ceilings. These roll forming machines play a vital role in suspended ceiling systems, ensuring the safety and aesthetics of the ceiling.

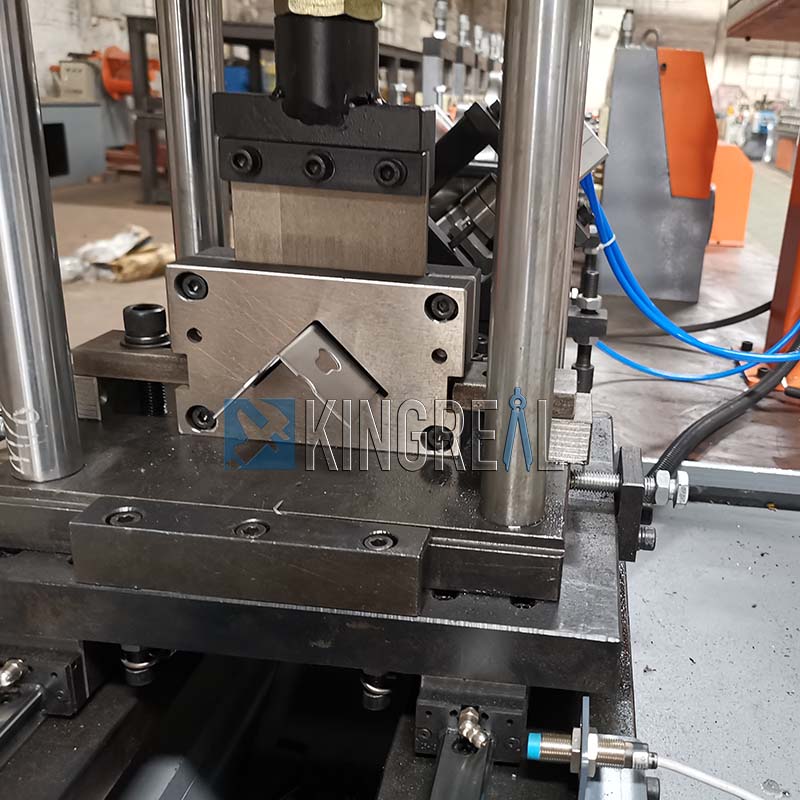

● Roll Forming Machine in Drywall System

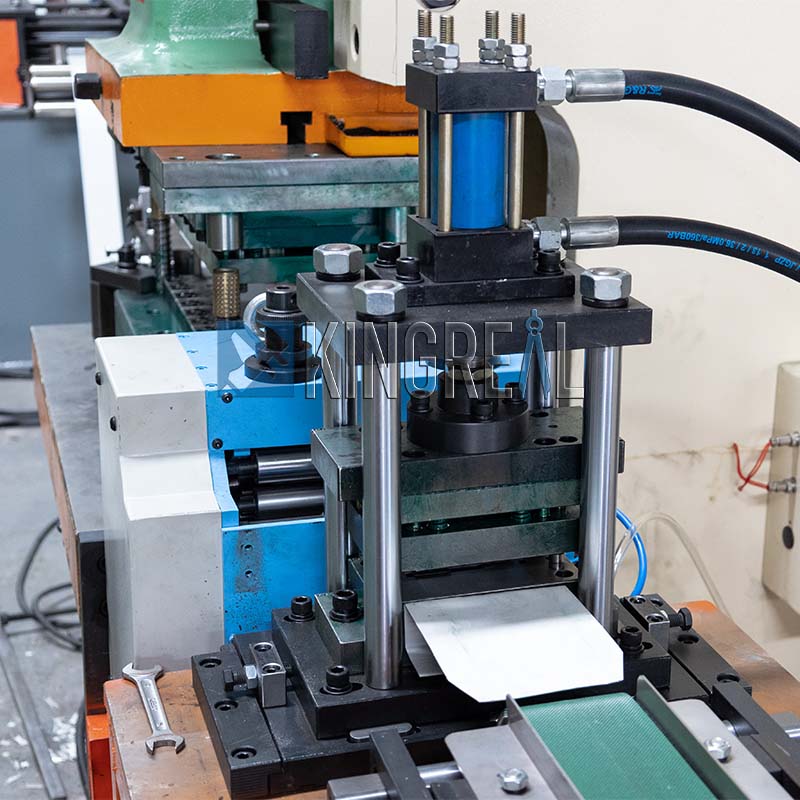

Drywall profile machines are crucial in drywall systems. KINGREAL drywall profile machine can produce studs and tracks of varying sizes, specifically for partition wall system installation. Drywall profile machines must produce components with precision and quality assurance to ensure they meet load standards, thereby ensuring the safety and stability of the wall.

Both studs and tracks in partition wall systems are produced using high-precision drywall profile machines, which not only improves production efficiency but also reduces labor costs. Thanks to KINGREAL high-quality drywall profile machines, customers can expect high-quality studs and tracks, ensuring a smooth and seamless installation process for every partition wall system.

● Roll Forming Machine in LGS Housing System

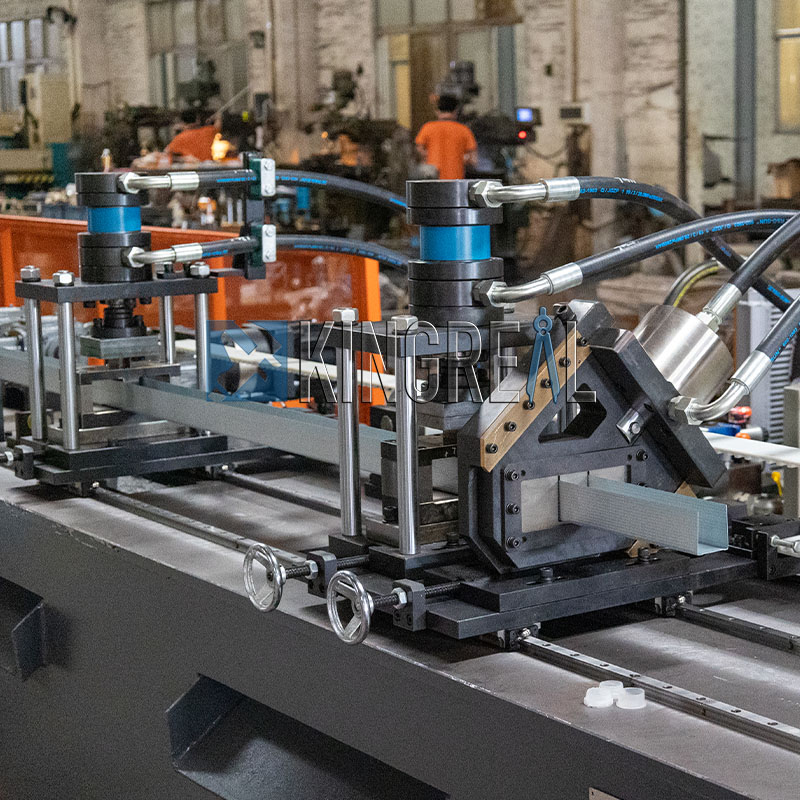

Roll forming machines are also widely used in housing construction. Light gauge steel frame machines use galvanized steel strip as raw material, cold-bending it to produce metal frames for construction. This metal frame is both strong and corrosion-resistant, making it suitable for a variety of building environments.

To facilitate the production of profiles directly at the construction site, KINGREAL also offers mobile light gauge steel frame machines. This light gauge steel frame machine, housed in a small truck, carries a light gauge steel frame machine and rolls of material, allowing it to be delivered directly to the construction site for production. This innovative solution significantly improves construction efficiency, allowing customers to quickly meet production needs on-site.

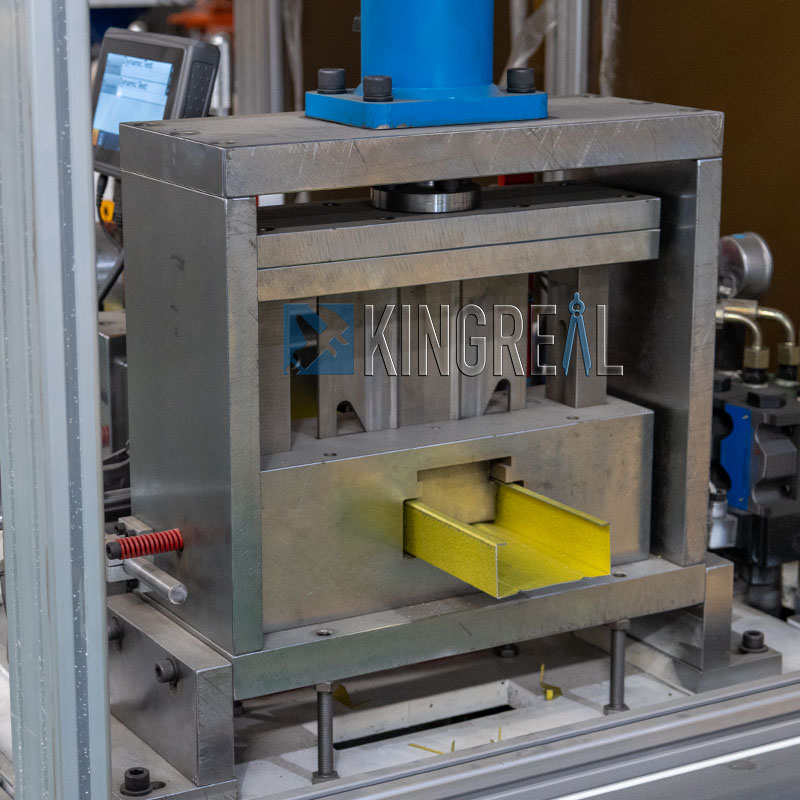

● Roll Forming Machine in Pallet Racking System

In pallet racking systems, components such as shelf panels, upright, box beams, and step beams are produced using roll forming machines. KINGREAL specializes in providing customers with equipment such as storage shelf panel machine, pallet upright rack machine, box beam making machine, step beam making machine, and slotted angle rack machine. The profiles produced by these roll forming machines can be assembled together to form complete racking systems, meeting both light and heavy-duty racking needs.

Using KINGREAL warehouse pallet rack machines, customers can achieve high-strength racking structures, ensuring stability and safety during load bearing and use. The flexibility and versatility of these roll forming machines provide customers with more options when designing and implementing racking systems.

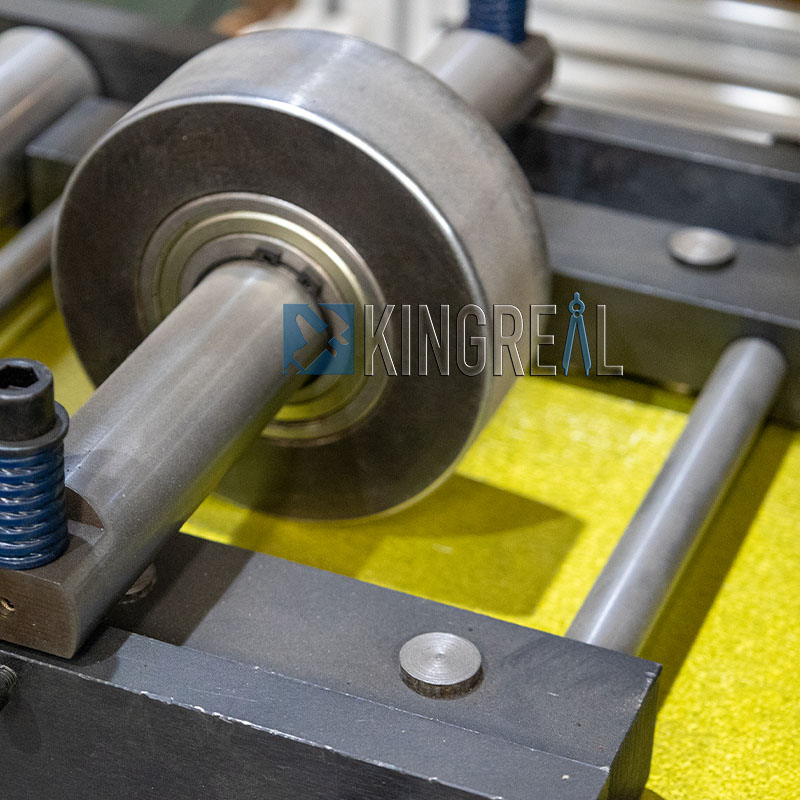

● Roll Forming Machine in Cable Tray System

For cable tray systems, KINGREAL offers a variety of cable tray making machines, including Cable Tray Cover Machines, Ladder Cable Tray Machines, Trough Cable Tray Machines, Solid Bottom Tray Machines, and Din Rail Channel Machines. Customers can select the most suitable cable tray type based on their specific needs.

The finished products produced by these cable tray making machines possess superior mechanical stability, capable of withstanding high loads, external factors such as foot traffic, dirt, and dust, ensuring effective protection of cables during use. By using these cable tray making machines, customers can obtain high-quality cable trays, enhancing the safety and durability of cable systems.

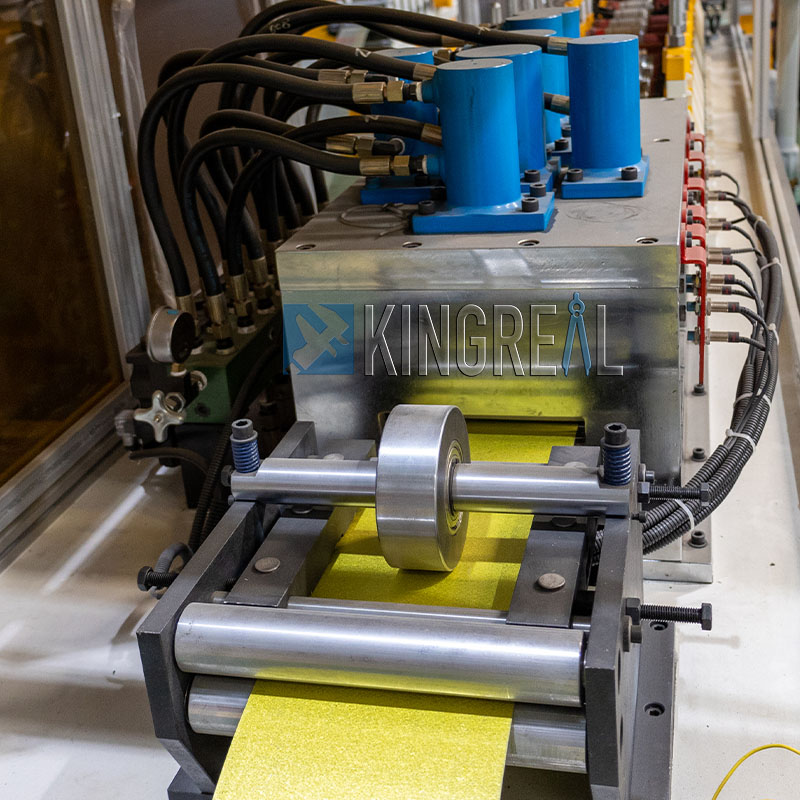

● Roll Forming Machine in Photovoltaic System

In photovoltaic systems, the use of solar channel roll forming machine is crucial. PV mountings are not only an essential component of a photovoltaic power plant but also support the operation of photovoltaic modules. The choice of mountings directly impacts the power generation efficiency, safety, and return on investment of a photovoltaic system.

KINGREAL solar channel roll forming machines can produce solar channels with various hole patterns and can be customized according to customer drawings. This flexibility allows customers to obtain high-precision, high-quality profiles tailored to their specific needs, thereby enhancing the overall performance and safety of the photovoltaic system.

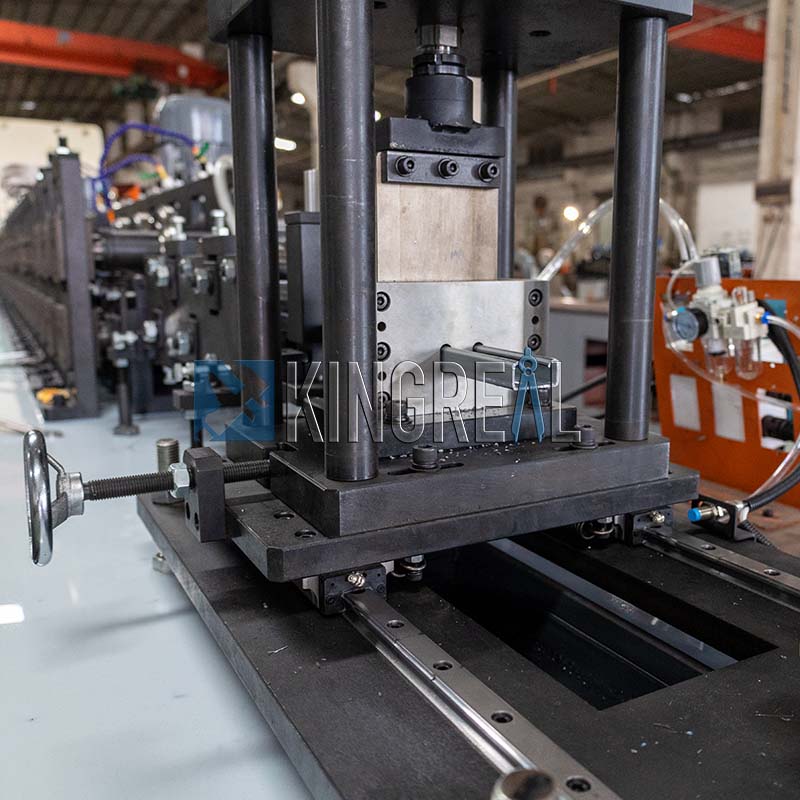

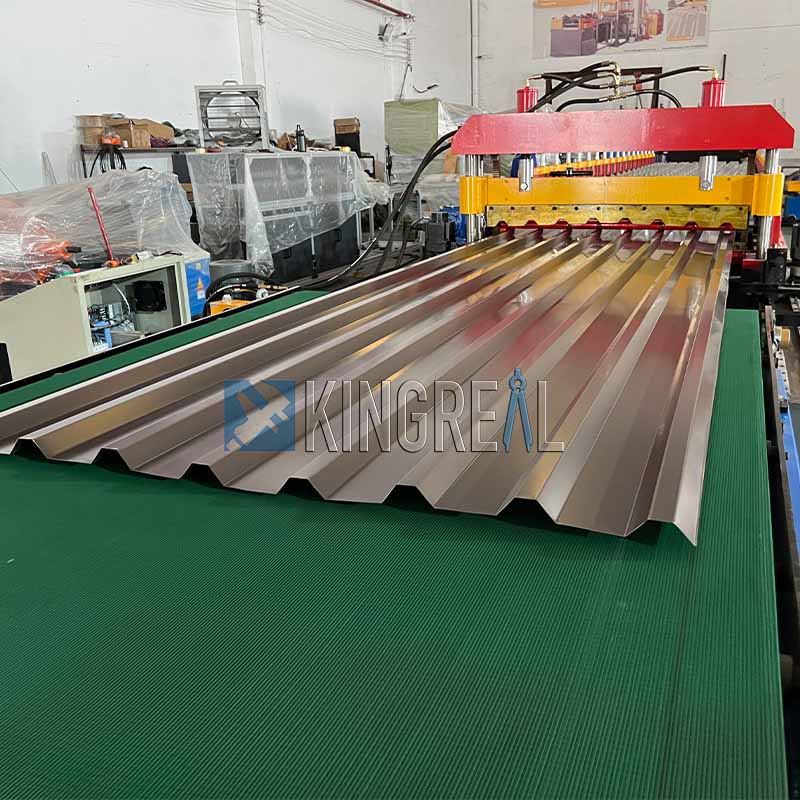

● Roll Forming Machine in Metal Roofing System

The production of metal roofs also relies on roll-forming machines. KINGREAL metal roof sheet making machines can produce various types of metal roof tiles, including ibr roof tile, glazed roof tile, metal roof ridge cap, and snap lock roof panel. The meticulously designed production process for these metal roof tiles ensures the strength and aesthetics of each tile.

Through close collaboration with customers, KINGREAL metal roof sheet making machines are able to provide metal tiles of varying sizes and types based on their specific production needs. This ensures that customers receive high-quality materials when constructing roofs, enhancing the durability and appearance of their buildings.

Overall, the application of roll forming machines is crucial across various industries. Leveraging its extensive experience and advanced technology, KINGREAL offers customers a diverse range of roll forming machine manufacturing solutions. These roll forming machines not only improve production efficiency but also ensure product quality and safety.

If you'd like to learn more about the capabilities of a roll forming machine, why not browse KINGREAL product line today? Alternatively, give KINGREAL dedicated team a call to discuss your needs—KINGREAL will be happy to assist.