How is ibr roof sheet making machine used in South Africa?

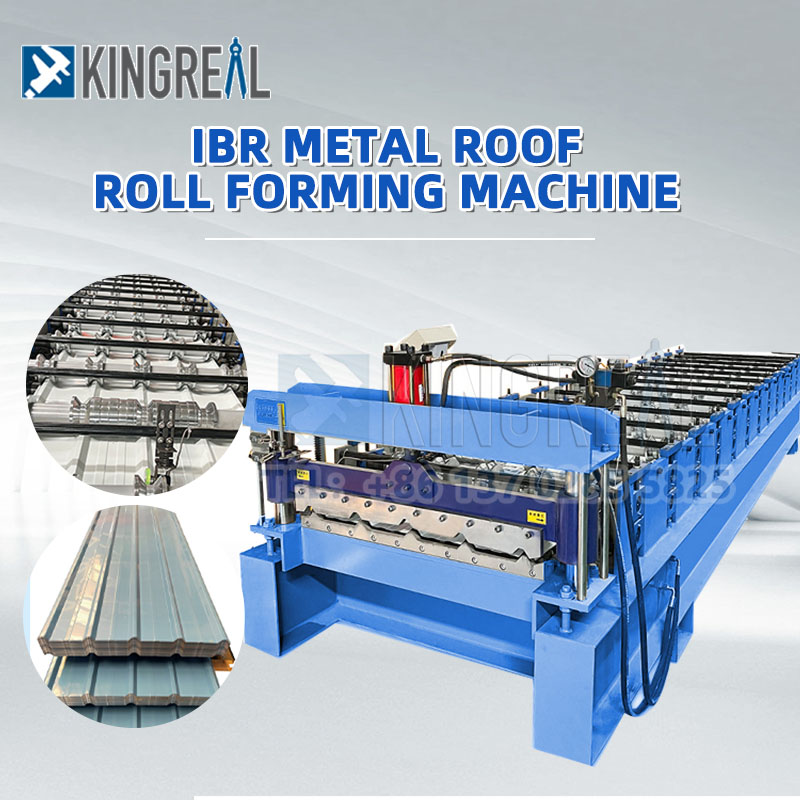

2025-07-15 12:00| IBR roof sheet making machine is a kind of equipment specially used for producing IBR roof sheets, which has important market value and application prospects. This ibr metal roof sheet making machine is designed to improve production efficiency, reduce costs and meet the diversified needs of modern buildings. With the rapid development of the construction industry in South Africa, ibr roof sheet making machine is more and more widely used in the market and has become an indispensable production equipment for construction companies and developers. |  |

1. Function of IBR Roof Sheet Making Machine

1.1 Working principle

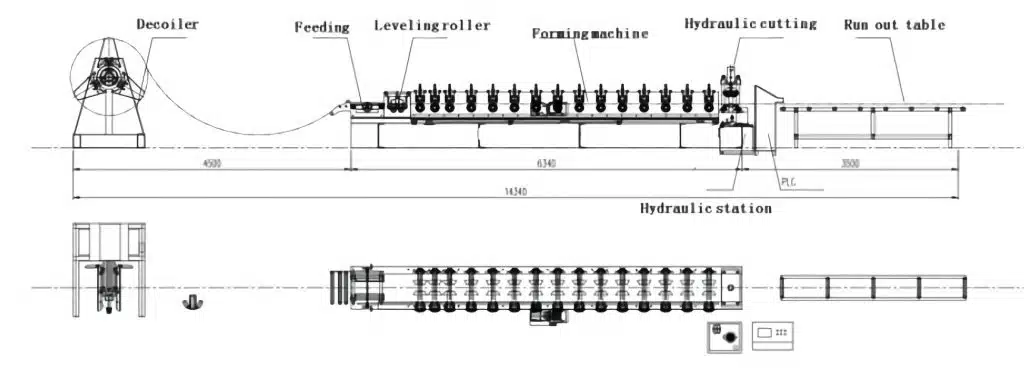

The working principle of IBR roof sheet making machine is relatively simple but efficient. Its core is to transform steel coils into roof sheets with specific shapes and specifications through a series of roller forming steps. The main components of the ibr metal roof sheet making machine include:

1

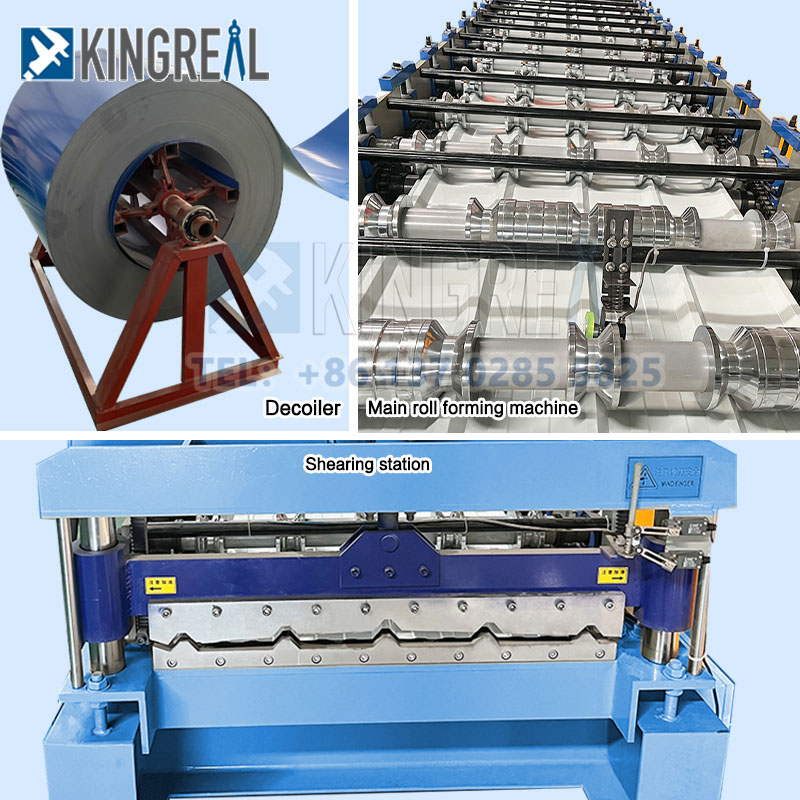

Decoiler

used to unwind the steel coils and prepare them for the forming process.

2

Main roll forming machine

steel is gradually formed into IBR roof sheets through multiple rollers.

3

Cutting device

cuts the formed roof sheets according to the set length.

4

Control system

responsible for the automatic control of the entire production process to ensure the coordinated operation of each link.

1.2 Production process

The steps of the production process are usually as follows: Uncoiling: Put the coil into the decoiler, and automatically uncoil it to prepare for forming. Forming: The steel coil passes through multiple rollers of the main roll forming machine to gradually form the shape of the IBR roof panel. Cutting: After reaching the set length, the roof panel is cut by the cutting device. Discharging: The cut roof panel is automatically sent out to complete the production process. |  |

2. Reasons for Demand for IBR Roof Sheet Making Machines in South African Market

2.1 Growth in infrastructure construction In recent years, South Africa's infrastructure projects have increased significantly, driving the demand for IBR roof tiles. The government has increased infrastructure investment and promoted the rapid development of housing and commercial buildings. IBR roof tiles have become a popular choice in construction projects due to their economy and durability.

Application of IBR roof tiles in construction IBR roof tiles are widely used in a variety of occasions such as industrial plants, warehouses, commercial buildings and residences. Its waterproof, heat-insulating and wind-resistant properties make it perform well in South Africa's climatic conditions and can effectively protect the building structure.

2.2 Economic and environmental protection IBR roof tiles are cost-effective. Compared with traditional building materials, IBR roof tiles have low production and installation costs, which can effectively reduce the overall cost of construction projects. In addition, the materials used in IBR roof tiles are recyclable, meet modern environmental protection requirements, and promote sustainable development.

Impact on the environment and sustainable development The production process of ibr roof sheet making machine is relatively environmentally friendly and can reduce material waste. Through efficient production processes, the production of IBR roof tiles not only meets market demand, but also contributes to environmental protection. |  |

3. Advantages of IBR Metal Roof Sheet Making Machine

3.1 Efficient production The production speed ofibr roof sheet making machine is fast and the degree of automation is high, making the production process more efficient. Compared with traditional manual production, the use of ibr metal roof sheet making machines has greatly increased production capacity and can complete a large number of roof tiles in a short time. In addition, the maintenance and operation of the ibr roof sheet making machine are simple, allowing enterprises to reduce labor costs and improve overall operational efficiency. |  |

3.2 Flexibility and adaptability IBR metal roof sheet making machine has strong flexibility and can adapt to the needs of different construction projects. For example, the ibr roof sheet making machine can produce roof tiles of different sizes according to customer requirements to meet diverse market needs. This flexibility enables ibr metal roof sheet making machines to maintain their advantages in a highly competitive market. According to the different needs of customers, IBR metal roof sheet making machines can produce roof panels of various sizes, which is convenient for customers to choose in practical applications. This diverse product selection enhances customers' market competitiveness. |  |

4. Market Prospects of IBR Roof Sheet Making Machines

4.1 Market trend analysis

The future outlook of the South African construction industry is very optimistic. With the government's continued investment in infrastructure, the market demand for IBR roof tiles will further grow. As a key equipment for the production of such roof tiles, ibr metal roof sheet making machines have broad market prospects. It is expected that the market size of IBR roof tiles will continue to expand in the next few years, bringing more opportunities for manufacturers and suppliers.

4.2 Competitive advantages

In the building materials market, IBR roof tiles are competitive with other building materials due to their superior performance and economy. Although traditional roofing materials such as concrete and ceramic tiles have their advantages in some aspects, IBR roof tiles have shown obvious advantages in terms of cost, ease of installation and maintenance.

IBR roofing tiles’ position in the market

IBR roofing tiles’ position in the South African market has gradually risen, becoming an important material that cannot be ignored in the construction industry. With the continuous advancement of technology, the performance of ibr metal roof sheet making machines has also been continuously improved, further consolidating the market position of IBR roofing tiles.

IBR roof sheet making machines play a vital role in the modern construction industry. Its efficient production capacity, flexible product selection and good market prospects make it an important equipment in the South African construction market. With a deep understanding of ibr metal roof sheet making machines, customers can make better choices to meet their own production needs.

If you have any questions about ibr roof sheet making machines or need further information, please feel free to contact KINGREAL. KINGREAL professional team will provide you with quality service and support to help you develop your business. Choosing ibr metal roof sheet making machines will enable you to occupy a place in the competitive market and achieve greater success.