What is metal roof ridge cap machine?

2025-06-30 12:00Introduction of Metal Roof Ridge Cap Machine

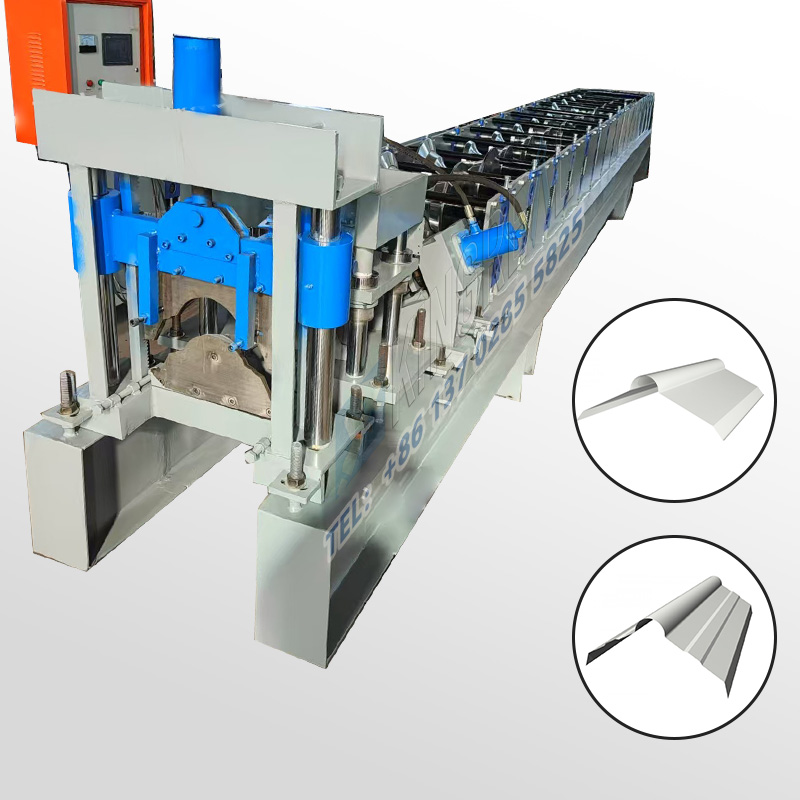

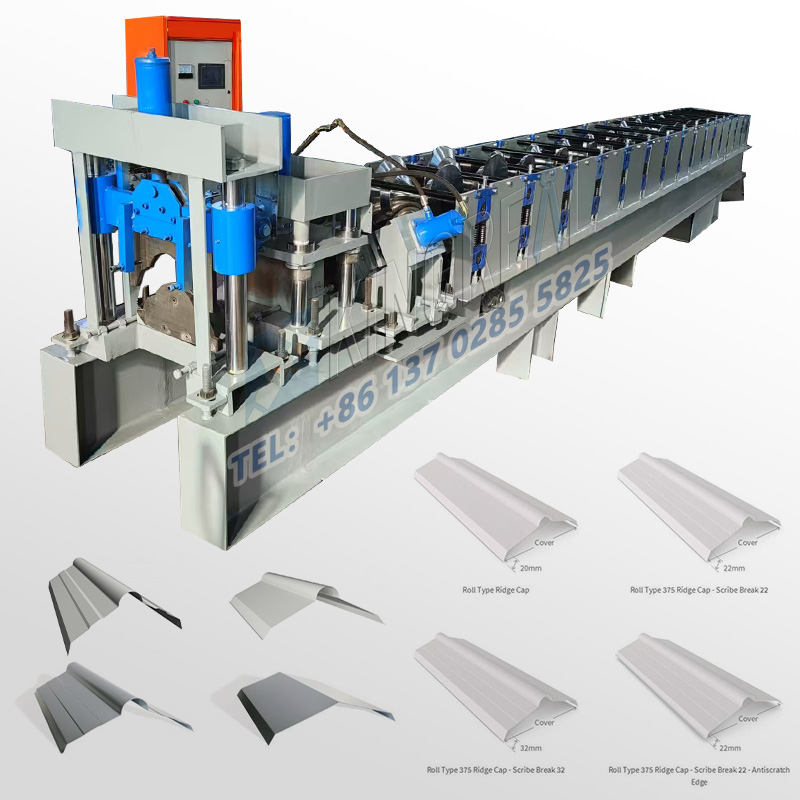

| Metal roof ridge cap machine is used to produce various types and sizes of ridge caps installed in the ridge line of the pitched roof, including angle ridge cap, square ridge cap, circular ridge cap and other common ridge cap types, all of which can be produced by KINGREAL ridge cap roll forming machines. The ridge cap is used to connect the vertices on both sides of the roof. It can provide your roof with a clean, maintenance-free, lightweight and completely weatherproof surface. It is cost-effective and a labor-saving and feasible solution to enhance the aesthetics of any building. Metal roof ridge is mainly used to keep the roof waterproof. If the ridge cap is not installed, rainwater will also flow down the chimney or the higher area of the roof tiles, and eventually flow into the house through the chimney through the roof. |  |

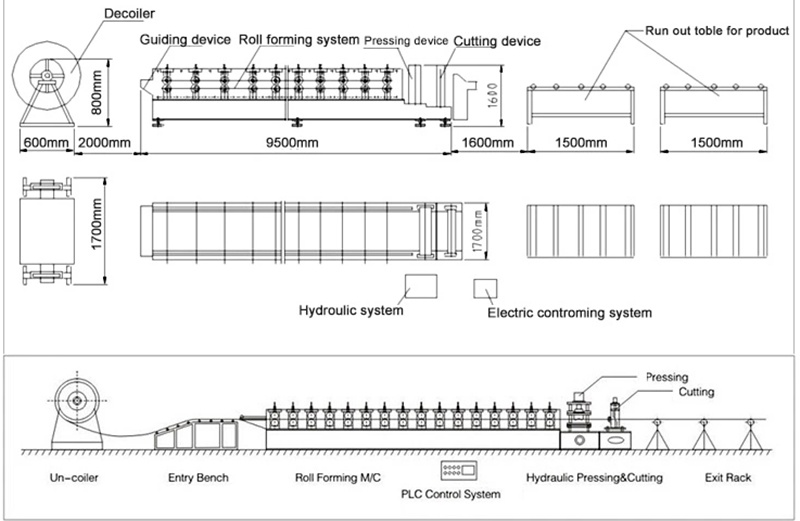

Working Process of Ridge Cap Roll Forming Machine

Decoiler ↓ Roll Forming Machine ↓ Cutting Station ↓ Output Table |  |

Parameters of Metal Roof Ridge Cap Machine

| Items | Standard model | High speed model |

| Total power | 5.5-7.5kw | 11-15Kw |

| Speed | 4-6m/min | 6-8m/min |

| Dimension(LxWxH) | (6-8)x(1.0-1.4)x1.4m | (6-8)x(1.0-1.4)x1.4m |

| Weight of machine | 3.5-5tons | 9-12tons |

| Roller station | 10-16 | 12-20 |

| Material thickness | 0.25-0.5mm(G300-G450) | 0.25-0.5mm(G300-G450) |

| Material width | 300;304;400;457mm | 300;304;400;457mm |

| Transmission system | Hydraulic motor | Servo motor with gear box |

| Cutting system | Hydraulic cylinder(front cutting) | Hydraulic cylinder(front cutting) |

| Control System | Automatic with PLC,HMI | Automatic with PLC,HMI |

Features of Ridge Cap Roll Forming Machine

-Adopt inverter, PLC, HMl for automatic roll forming and cutting;

-Automatically set the length through the touch screen;

-Rollers and blades are made of alloy steel and SKD11 steel with a hardness of 60-62HRC;

-Electrical and hydraulic components are made of well-known domestic and foreign brands;

-Powerful power, solid body frame, stable operation

-The hydraulic system is equipped with a cooling system, which allows the metal roof ridge cap machine to run continuously for 20 to 22 hours a day.

Special Process of Metal Roof Ridge Cap Machine

1. Roll-forming process for ridge cap roll forming machine The metal roof ridge cap machine uses an advanced roll-forming process to process flat metal sheets or coils into the required ridge cap profile. This process usually involves multiple rolling stations, and through precise mechanical operations, the metal sheets are gradually bent and formed to form a specific ridge cap shape. According to different customer requirements, the shape and size of the ridge cap will vary, so KINGREAL has equipped the ridge cap roll forming machine with a set of custom-designed rollers and molds. This flexible design allows the machine to adapt to the needs of a variety of roofing systems, thereby meeting the personalized needs of different customers. 2. Cutting process for metal roof ridge cap machine After the ridge cap is formed, the cutting process is the next important step. KINGREAL has equipped this metal roof ridge cap machine with an efficient cutting system that can trim the formed ridge cap section to the precise length required. This cutting system is not only efficient, but also highly intelligent, and can automatically alarm and pre-cut before the order is completed. In this way, the error in the production process can be effectively controlled to ensure that the size of each ridge cap section meets the customer's requirements. |  |

Advantages of Ridge Cap Roll Forming Machine

1. Efficient and stable mass production

The metal roof ridge cap machine is capable of efficient and stable mass production of ridge caps. Whether it is small batch or large-scale production, the ridge cap roll forming machine can ensure the consistency and high quality of all manufactured parts. Through optimized production processes and high-precision mechanical control, manufacturers can complete large orders in the shortest time, greatly improving production efficiency.

2. Support customized production

The requirements of each construction project may be different, and the size and shape of the ridge caps vary greatly. KINGREAL metal roof ridge cap machine has good customization capabilities and can produce ridge caps of different sizes and shapes according to specific roofing requirements. This flexibility provides customers with more choices.

3. Simplify the production process

Using the ridge cap roll forming machine, manufacturers can effectively simplify the production process and reduce labor costs. Through the automated forming and cutting process, the need for manual intervention is reduced, thereby reducing operational risks and improving production stability. Moreover, the ridge cap roll forming machine’s intelligent control system can monitor the production status in real time to ensure the continuity and efficiency of production.

4. Precise quality control

In the construction industry, the weather resistance and durability of the ridge cap are crucial. KINGREAL metal roof ridge cap machines provide precise control to ensure that each ridge cap meets strict weather resistance and durability standards. By adopting high-quality materials and advanced production processes, the machine is able to produce ridge caps that meet international standards to meet the needs of the market.

5. Multiple metal material compatibility

The ridge cap roll forming machine is designed with the diverse metal material needs in the market in mind and is compatible with a variety of metal materials, including steel, aluminum and other metals. This compatibility allows KINGREAL metal roof ridge cap machines to handle a variety of specific materials required by customers in different projects. If customers have special metal material production and processing needs, KINGREAL also welcomes consultation to provide the best solution.

Application of Ridge Cap Roll Forming Machine

| The ridge cap is a protective and decorative component covering the ridge or ridge of the roof, playing a vital role in preventing water penetration and protecting the structural integrity of the roof. The choice of metal ridge cap profiles will affect the functionality and aesthetics of the roofing system. The choice of the type and size of the ridge tile is mainly free to choose according to the applicable scenario. KINGREAL can provide corresponding metal roof ridge cap machines for various types of roof ridge caps to help customers complete efficient production. |  |

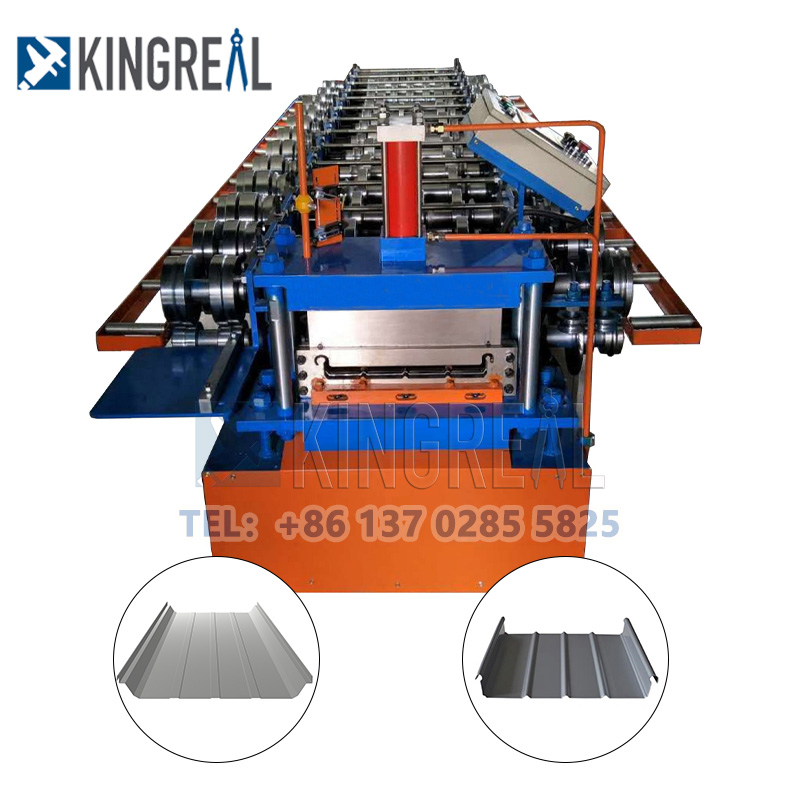

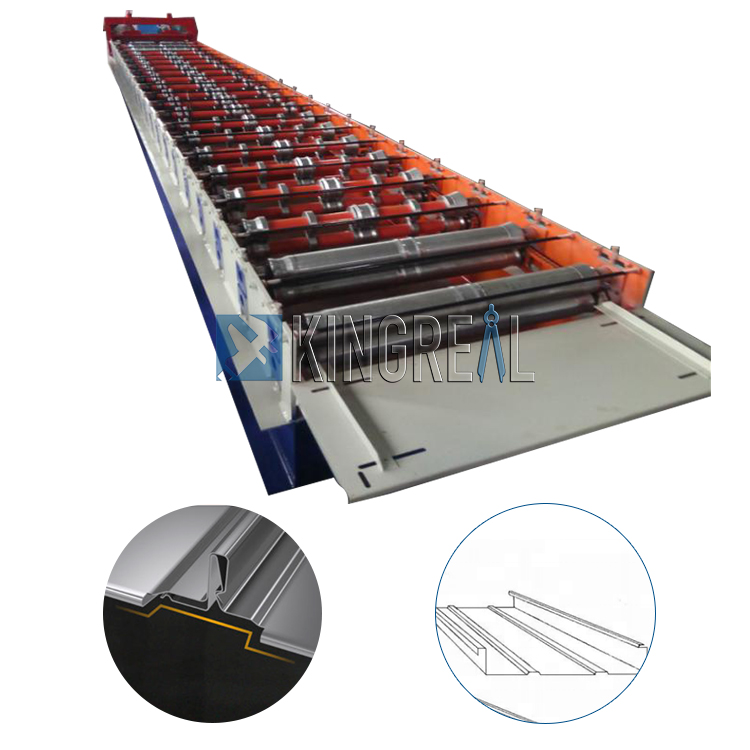

Related Metal Roofing Machines

Addition to ridge cap roll forming machine, KINGREAL also can provide various types of metal roofing machines, including ibr roof sheet making machine, double layer roofing sheet machine, glazed tile roll forming machine, trapezoidal sheet roll forming machine, corrugated roofing tile machine, standing seam roof panel machine,snap lock roof panel machine,etc.