KINGREAL technological innovation --perforated metal machine

2025-05-09 12:00KINGREAL is a professional perforated metal machine manufacturer with more than two decades of industry experience. KINGREAL specializes in designing and manufacturing various types of sheet metal perforation machines, including metal ceiling perforation line, perforated metal machine with cutting, and sheet metal perforation machine with rewinding. Through cooperation with customers in Bangladesh, UAE, Turkey, Saudi Arabia, India, and North Korea, KINGREAL continues to be inspired to promote technological innovation to meet the growing needs of the market.

In this article, KINGREAL will discuss in depth KINGREAL technological innovation in the field of perforated metal machines, especially the breakthroughs in aperture and sheet metal perforation machine configuration, and show how KINGREAL improves the competitiveness and customer satisfaction of perforated metal machines through technological progress.

Technological Innovation in Sheet Metal Perforation Machine

1. Innovation in Aperture

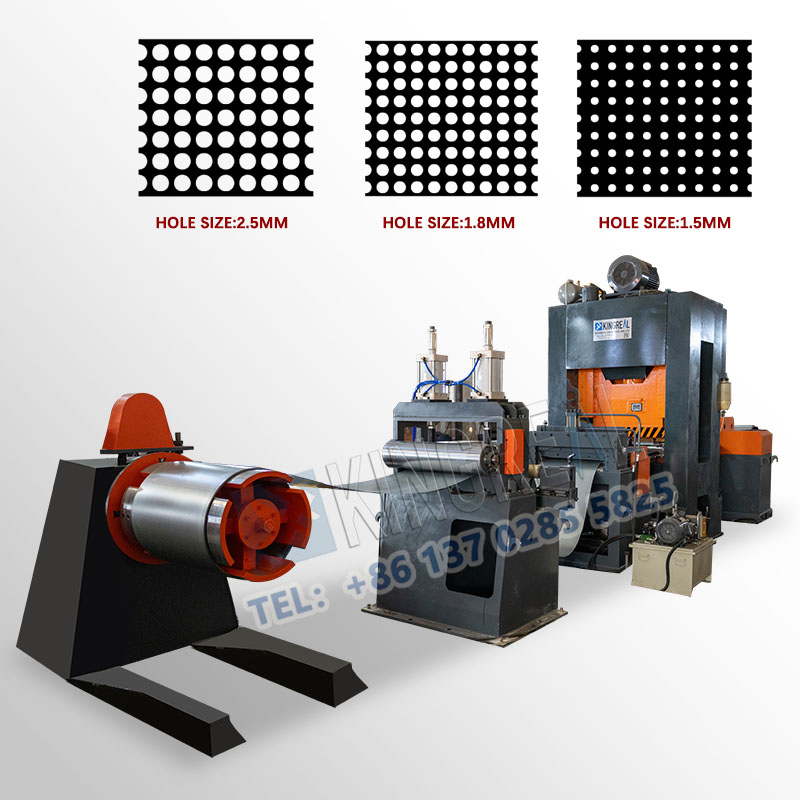

The core function of a perforated metal machine is to be able to punch holes efficiently and accurately on metal sheets. Traditional sheet metal perforation machines usually provide apertures of 1.8mm and 2.5mm. However, with the continuous development of industrial applications, the demand for micro apertures is increasing. This is because many industries (such as electronics, automotive, and construction) are increasingly inclined to use micro apertures to achieve higher performance and smaller components when designing products.

1.1 Market demand for micro-apertures

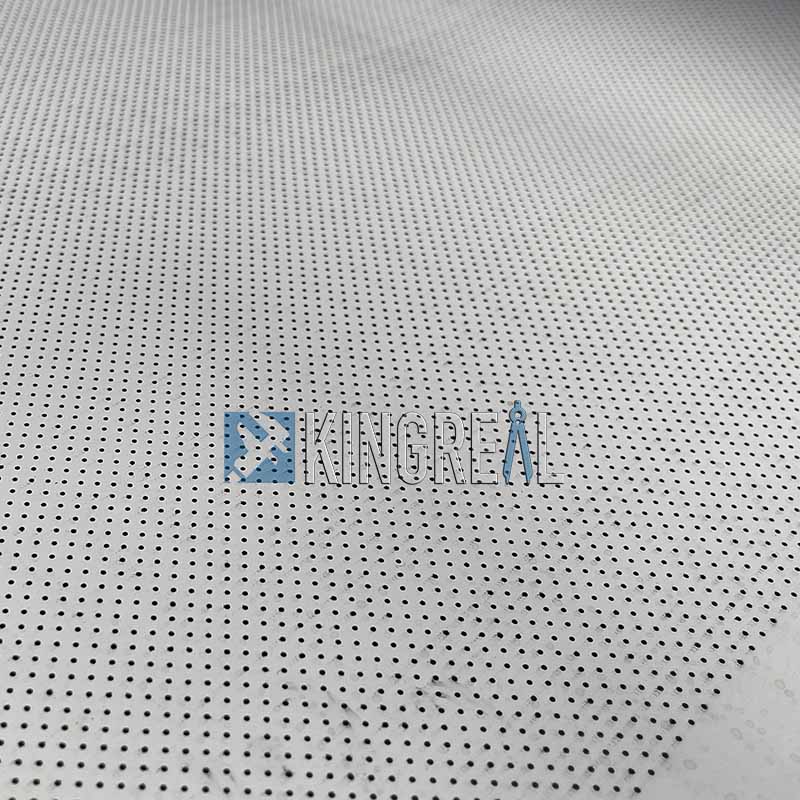

Micro-apertures are critical in a variety of application scenarios. For example, in electronic products, micro-apertures can help achieve higher heat dissipation performance and more compact component design. For the automotive industry, the use of micro-apertures can reduce vehicle weight and improve fuel efficiency without compromising safety and strength.

In order to meet this market demand, KINGREAL engineers conducted in-depth research and development. After many attempts, they successfully designed a perforated metal machine that can punch out micro-apertures for Moroccan and Greek customers. It can punch out 1mm and 1.5mm holes. This technological innovation not only enhances KINGREAL market competitiveness, but also provides new production possibilities for our customers.

1.2 Difficulty in punching die manufacturing

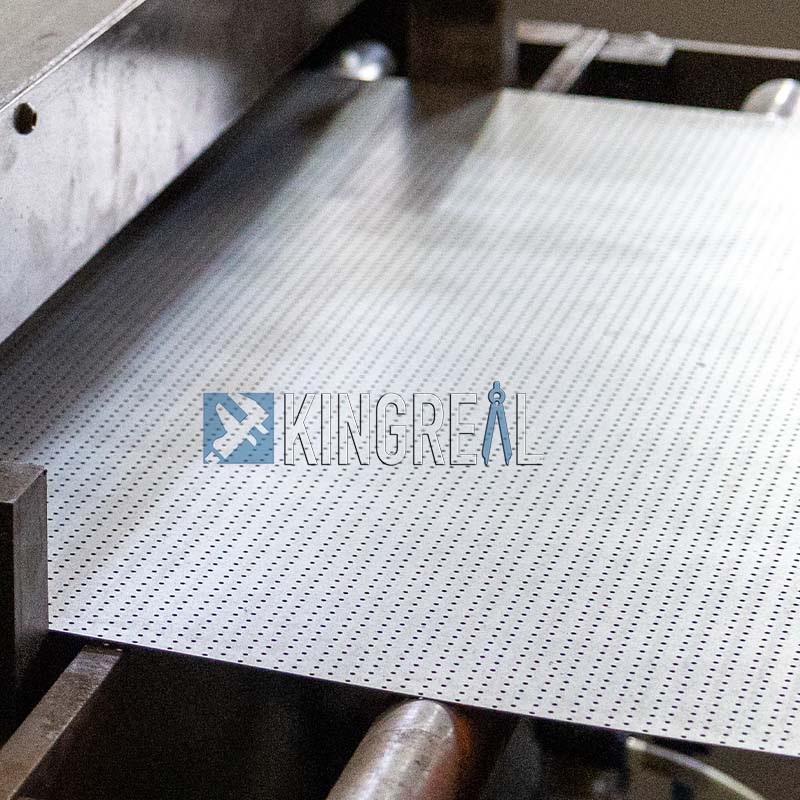

The manufacture of micro-aperture punching dies involves extremely high precision requirements. The difficulty in making the die is that the processing accuracy and strength of small-size holes must be guaranteed. Micro-aperture dies need to use high-quality materials to ensure that they will not wear or deform under high-frequency operation. In addition, the design of the die must also take into account the material properties during the punching process to avoid material tearing or deformation.

KINGREAL engineering team has extensive experience in this field. They have successfully overcome these technical difficulties by optimizing mold design and production processes, allowing our sheet metal perforation machines to efficiently and stably produce metal parts with micro-apertures.

2. Innovation in configuration

In addition to technical innovations in aperture, KINGREAL has also made significant improvements in the KINGREAL configuration of the perforated metal machine. According to the production needs of different customers, KINGREAL divides the perforated metal machine into a coil to coil perforation line and a sheet metal perforation machine with cutting. However, the production needs of many customers involve the alternating use of punching and cutting , punching and rewinding.

2.1 Design of flexible sheet metal perforation machine

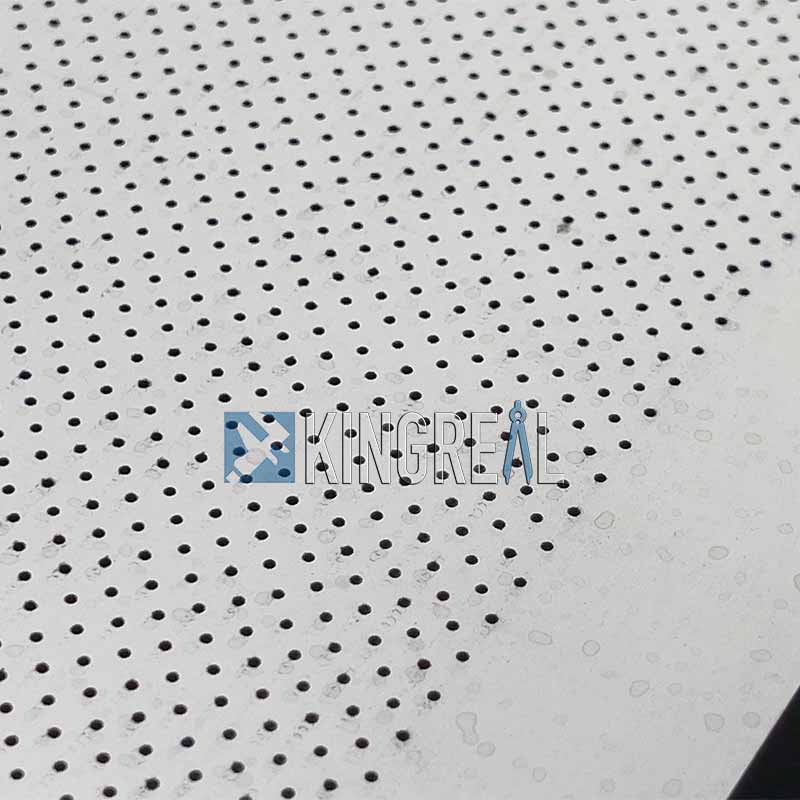

In order to meet this demand, KINGREAL designed a perforated metal machine for customers that can both wind or shear. This flexible design allows customers to easily switch between different production scenarios. Specifically, when customers need to shear, they only need to open the cutting station and close the recoiler; when they need to wind, they can do the opposite.

This design not only helps customers save sheet metal perforation machine procurement costs, but also reduces the floor space of the perforated metal machine and improves work efficiency. Customers do not need to buy two sheet metal perforation machines with different configurations, only one device is needed to meet multiple production needs.

2.2 Convenience of operation

In addition, another significant advantage of this configuration is the convenience of operation. Using one device for multiple functions, the operator only needs to understand one set of operating procedures to flexibly respond to different production tasks. This convenience not only improves production efficiency, but also reduces training costs, allowing new employees to get started faster.

KINGREAL International Cooperation and Technical Feedback

Through cooperation with customers in many countries, KINGREAL continues to obtain technical feedback and first-hand information on market demand. These experiences provide important references for KINGREAL technological innovation.

1. Cooperation with Morocco and Greece In cooperation with customers in Morocco and Greece, KINGREAL learned about the strong local demand for micro-apertures. They hope to produce more metal parts suitable for electronic products, which provides a practical basis for our micro-aperture perforated metal machine technology. After repeated testing and adjustments, we finally provided customers with an efficient and stable sheet metal perforation machine that met their production needs. | 2. Feedback in the Middle East Market In the Middle East markets such as the UAE and Turkey, KINGREAL perforated metal machines have also received good feedback. Local customers highly recognize the flexible configuration of the sheet metal perforation machines, because it enables them to quickly adjust production methods in different projects and improve production efficiency. |