Light Steel Frame Machine:The Future of Industrial Production

2025-11-13 14:35"In the modern construction industry, the light steel frame machine has revolutionized traditional construction methods. Using galvanized steel as raw material, light gauge steel frame machine produces metal frames such as wall panels, floor trusses, and roof trusses through a cold-bending process, widely used in the construction of light steel structure houses. With the diversification and efficiency demands of the construction industry, the light gauge steel frame machine has brought high-quality, lightweight, and easy-to-install profiles, especially in areas with increasing demand for adding floors, renovations, and reinforcements to existing buildings, as well as in regions with material shortages or transportation difficulties.

In this article, KINGREAL will explore how the light steel frame machine is shaping the future of industrial production and its importance in modern construction."

Development of Light Gauge Steel Frame Machine

Traditional building materials such as concrete and wood have dominated for decades. However, with the rapid changes in the construction industry, the construction methods using these materials have become slow, chaotic, and costly, failing to meet the demands of modern construction for speed, precision, and sustainability. Therefore, the light gauge steel frame machine offers a completely new solution for the construction industry. Profiles produced using these light steel frame machines allow for construction four times faster than concrete construction, are 100% recyclable, and possess excellent weather resistance.

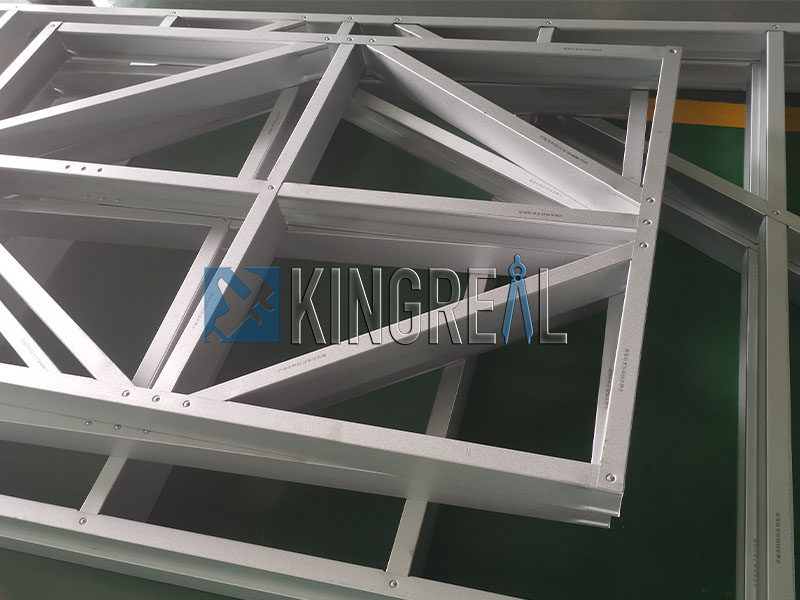

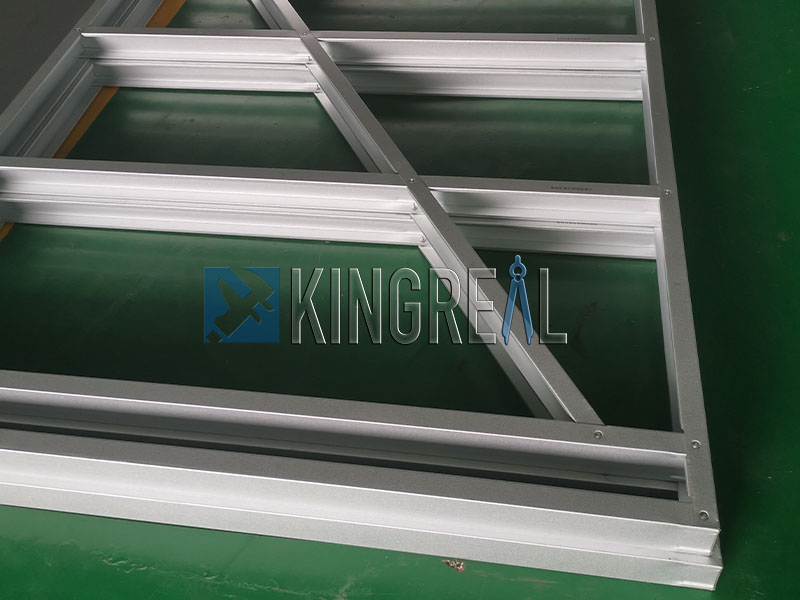

Precise and efficient production is achieved through software-driven light gauge steel frame machines. Modern steel frame systems replace traditional materials with precision-formed galvanized profiles, constructing a complete skeleton for the building. From walls to roof trusses, each component is pre-designed and precisely cut to the required dimensions by the light steel frame machine. Once delivered to the construction site, assembly is rapid, clean, and requires minimal manual labor. In most cases, a two-story light steel frame house can be completed in just a few weeks, followed by exterior cladding, insulation, and interior finishing.

Diverse Light Steel Frame Machine Solutions

KINGREAL light steel frame machines are designed with attention to detail, balancing practicality and aesthetics. KINGREAL light gauge steel frame machines can meet the needs of all light steel frame projects. Here are some standard punches that KINGREAL light steel frame machines can produce:

1. Lip Notch

Lip notches facilitate profile assembly, allowing them to interlock during installation. This function is automatically formed during production, greatly improving installation efficiency.

2. Swage

The Swage process is automated in specific areas of the profiles to ensure easy interlocking between them during assembly. This stamping process ensures the cladding or drywall is completely flush with the frame and enhances the final durability of the joint between the posts and panels.

3. Dimple

The Dimple function creates a small hole in the center of the flange for proper positioning of the connected profiles. This ensures the countersunk bolt heads are flush with the profile wall, allowing the drywall to fit smoothly onto the frame.

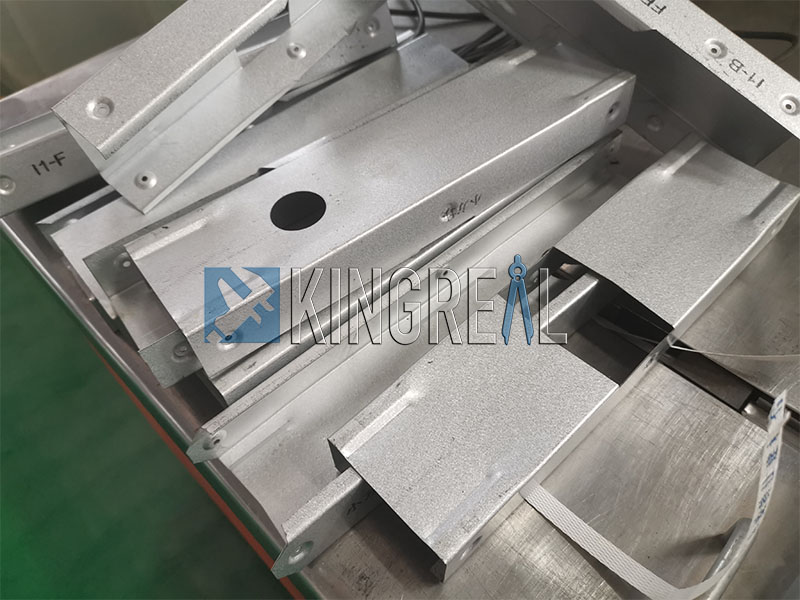

4. Service Hole

Service Holes are holes automatically added to the wall panels at locations specified during the design phase. These holes provide space for cable or conduit installation, simplifying subsequent construction.

5. Web Notch

Web Notch is an automatic slotting of the profiles to facilitate assembly when they interlock. This design is stamped into the bottom area of the profile during production, further improving assembly efficiency.

Furthermore, KINGREAL can design fully customized punching molds based on customers project needs. These punching molds can be easily integrated with the light gauge steel frame machine to meet specific project requirements.

Advantages of Light Steel Frame Machine in Industrial Applications

1. Full customized light steel frame machine

Light steel frame machine are designed using specialized software, enabling architects and engineers to create fully customized structures. One of the biggest advantages of light steel structures is their design flexibility. Customers can adjust wall thickness, height, span, and even integrate them into modern facade designs without sacrificing structural strength. This high degree of customization allows buildings to better adapt to different environments and customers needs.

2. High speed light gauge steel frame machine

The light steel frame machine boasts incredible production speeds, producing complete profiles in minutes. Small residential projects typically require only 1-2 days of light gauge steel frame machine processing to complete all production, with on-site assembly usually taking less than a week. Compared to concrete or brick structures that require months, light steel structures can reduce delivery time by up to 70%. Faster production speeds also mean faster project turnaround times, providing greater flexibility for modular and prefabricated builders.

3. Low maintenance costs for light steel frame machine

The profiles produced by the light gauge steel frame machine are characterized by low maintenance costs and a long service life. These steels will not rot, deform, or corrode, reducing long-term maintenance expenses and improving the economics of construction.

4. Environmental protection & sustainability for light steel frame machine

Modern construction increasingly emphasizes environmental protection and sustainability, and the galvanized steel used in the light gauge steel frame machine is not only recyclable but also generates relatively little waste during production. This makes light steel structures an ideal choice for sustainable development in the construction industry.

5. Adapting to diverse building needs

With the acceleration of urbanization, building needs are becoming increasingly diversified, and the light steel frame machine can efficiently meet these needs. Whether it's high-rise buildings, residential communities, or temporary facilities, light steel structures offer flexible solutions.

Contact KINGREAL for more information about the light gauge steel frame machine.