Metal Slitting Lines in HVAC Industry

2025-11-18 17:01"Modern construction and industrial systems depend much on the HVAC sector. Many parts of HVAC systems depend on premium metal processing, notably those for heating and cooling. Cutting vast coils of metal (like as galvanized steel or aluminum) into thin strips for further manufacturing into the intended final items, metal slitting machines are vital tools. The several benefits metal slitting machines provide in the HVAC sector will be discussed in depth in this essay."

1. The Importance of Metal Slitting Machines in HVAC Industry

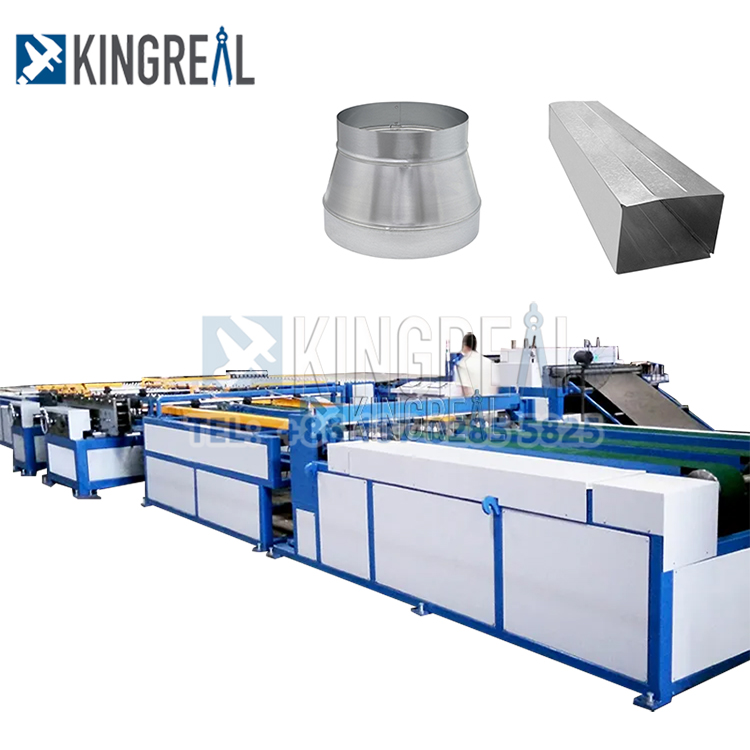

Metal slitting machines are indispensable equipment in the HVAC manufacturing process. In HVAC systems, the production of many finished products requires metal slitting machines to cut coils of material to suitable widths. These narrow strips are then cut into components of several forms, including rectangular ducts, round pipes, and other air distribution parts.

In addition to guaranteeing cutting accuracy, metal slitting lines raise production efficiency. Producing at extremely great speeds, a high-efficiency metal slitting machine guarantees large-volume processing in a brief amount. Metal slitting machines can fit demands whether for tiny-batch customisation or large-scale manufacturing requirements. Manufacturers can precisely manage the quality of every product with this metal slitting line, therefore guaranteeing that every part satisfies demanding criteria before it is offered to the market.

2. Precision and Efficiency of Coil Processing

One of the biggest advantages of metal slitting machines in the HVAC industry is their extremely high cutting precision. During manufacturing, HVAC manufacturers typically need to cut large coils of metal (such as galvanized steel or aluminum) into multiple narrow strips of varying widths to facilitate subsequent processing. This precise cutting capability is crucial for producing rectangular ducts, circular pipes, and other air distribution components. By using metal slitting machines, manufacturers can not only ensure that the width of each strip meets stringent tolerance requirements but also improve production efficiency and effectively reduce material waste.

Firstly, metal slitting lines have high-speed cutting capabilities, reaching production speeds of up to 230 m/min. This high efficiency allows HVAC manufacturers to complete large-volume cutting tasks in a shorter time.

Secondly, the advanced design of the metal slitting line minimizes material waste. When employing more expensive coated materials, decreasing material waste becomes particularly crucial. By means of accurate cutting, metal slitting machines enable producers to use every inch of material, hence avoiding waste generation throughout manufacturing.

Furthermore, metal slitting line enable precise parameter settings via a data control system, hence maximizing every detail of the cutting process, hence improving material use. Manufacturers can actually change the cutting width and thickness in real time depending on production needs.

Additionally, in HVAC systems, even the slightest error can obstruct airflow and affect the efficiency of the entire system. Metal slitting lines, through precise cutting, produce highly consistent components, ensuring the overall performance of the HVAC system.

3. Cost-Effectiveness of Using a Metal Slitting Machine

Metal slitting lines allows manufacturers to rapidly expand production capacity while minimizing capital expenditure.

KINGREAL metal slitting machines are equipped with advanced control systems and fully automated operation, greatly improving ease of operation and efficiency. Compared to traditional equipment, modern metal slitting lines not only enable large-scale standardized production but also allow for flexible adjustments to meet the production needs of narrow strips of varying widths. In large-scale production, metal slitting machines achieve efficient automatic feeding and cutting, reducing manual intervention and improving the overall efficiency of the production line. In small-batch custom production, the flexibility of metal slitting machines lets producers rapidly modify production settings to fulfill orders of several needs.

4. Adapting to Evolving HVAC Standards

As HVAC industry standards continue to evolve, especially with a strong focus on energy efficiency and airflow optimization, metal slitting lines play a crucial role in improving product quality and aligning with new standards. Metal slitting machines offer manufacturers significant flexibility, enabling them to quickly adjust production lines to create more compact and efficient duct systems, supporting adaptation to industry changes.

Modern HVAC design increasingly emphasizes energy efficiency, with smaller duct diameters and superior airflow performance requiring manufacturers to continuously optimize product designs. Metal slitting machines are key equipment for achieving these goals. They can quickly cut narrow strips suitable for new designs, helping manufacturers create equipment that meets the latest design standards.

The flexibility of metal slitting machines is also reflected in their ability to process different materials and thicknesses. When manufacturing airflow-optimized ducts, the use of various materials needs to be matched with the cutting capabilities of the equipment. Whether it's traditional galvanized steel or thinner aluminum, metal slitting lines can handle it with ease. This diversity allows manufacturers to choose from a wider range of materials to meet customer and market demands.

In the context of the increasingly international HVAC industry, various environmental regulations and standards are constantly evolving. The high efficiency and precision of metal slitting machines enable manufacturers to respond quickly and adapt to the regulatory requirements of different countries and regions.

5. KINGREAL Provides Complete HVAC System Solutions

KINGREAL not only provides high-quality metal slitting lines but also a range of volume control damper machines, forming complete ventilation system solutions. Including ●fire smoke damper machine, fire damper blade machine, tdc flange machine, tdf flange machine, and HVAC duct making machine●, these volume control damper machines produce different profiles that together constitute a complete HVAC system.

The advantages of choosing KINGREAL metal slitting lines and volume control damper machines are as follows:

First, customers receive a complete set of machines, ensuring seamless integration between equipment and avoiding the hassles of working with multiple suppliers.

Second, if problems arise during equipment use, KINGREAL will be responsible for subsequent troubleshooting, repair, and spare parts supply, ensuring a rapid return to normalcy for the user's production line.

Finally, KINGREAL has extensive experience in ventilation system solutions and can provide customized equipment manufacturing solutions and recommendations based on the customer's actual project needs and the local climate, helping customers achieve optimal production efficiency.

If you would like to learn more about KINGREAL metal slitting machines and other volume control damper machines, please visit the KINGREAL official website or contact the KINGREAL team directly. KINGREAL will be happy to provide you with professional consultation and support.