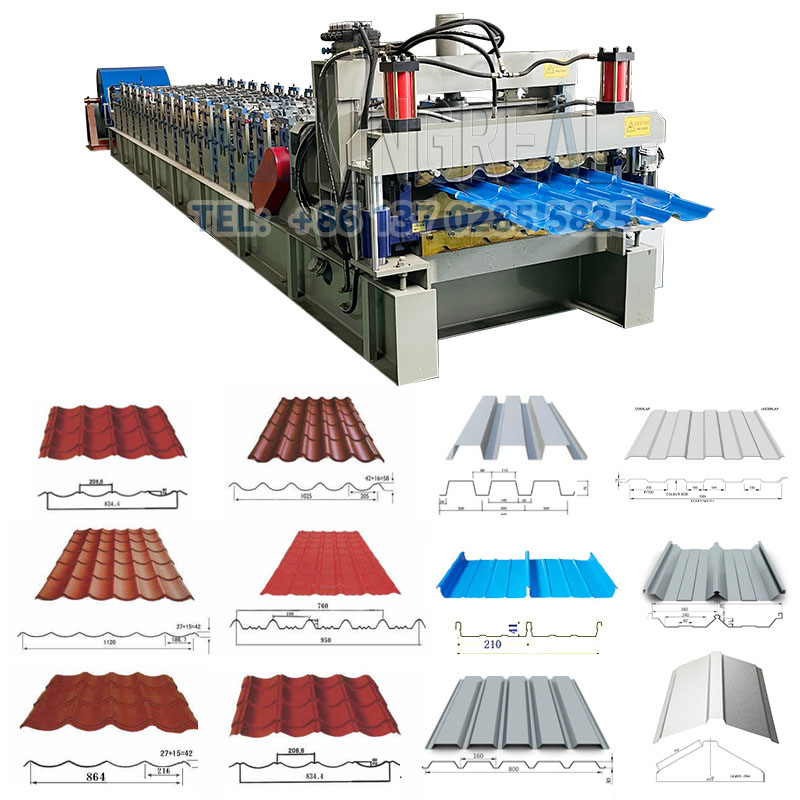

New design:glazed tile roll forming machine

2025-06-11 12:00| The performance and efficiency of production equipment have grown especially crucial in the building sector today as market demand grows and technology advances constantly develop. KINGREAL has made extensive technical improvements and parameter changes on the glazed tile roll forming machine to better satisfy consumer needs. The goals of this series of upgrades are to increase production efficiency, guarantee product accuracy, and offer consumers more effective and dependable glazed tile making machine solutions. |  |

Overview of Glazed Tile Roll Forming Machine

In the construction sector, glazed tile making machine is a piece of equipment especially used for creating glazed tiles, often employed for roofing, wall, and other decorative applications. Mostly comprised of a feeding platform, a shearing apparatus, a hydraulic station, a computer control system, and a primary roll forming machine, the glazed tile making machine is Small size, light weight, and easy transportation characterize the glazed tile roll forming machine. Its one-machine-multipurpose design, meanwhile, enables tiles of different specifications depending on several demands.

The advantages of the glazed tile making machine are not only reflected in its structural design, but also in its performance. First of all, the glazed tile roll forming machine uses less power, which can effectively save energy consumption and reduce production costs. In addition, the design of the glazed tile making machine also reduces dependence on manual labor, reduces labor intensity and improves production efficiency. Glazed tiles themselves have various colors, good gloss, corrosion resistance, acid and alkali resistance and other characteristics, which meet the market's dual needs for beauty and functionality. |  |

Workflow of Glazed Tile Making Machine

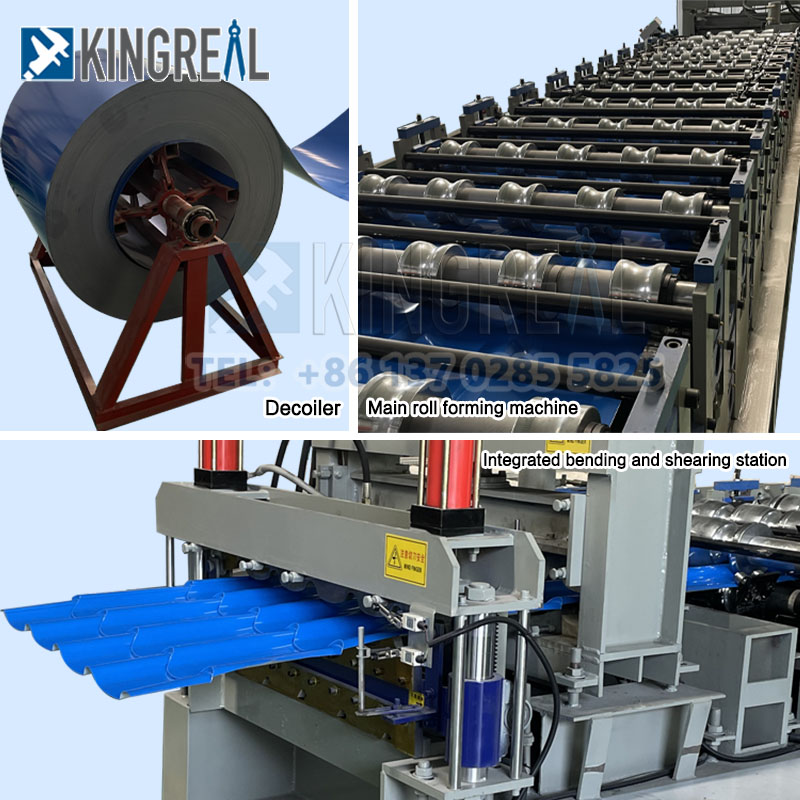

Feeding platform (optional): used to transport raw materials to the equipment. ↓ Decoiler (passive/automatic): Unwind the coil and prepare to enter the forming process. ↓ Front shearing (optional): Shear the material as needed. ↓ Feeding and guide table: Ensure that the material is accurately fed into the forming system. ↓ Film covering (optional): Add a protective film to the product to prevent scratches. ↓ Roll forming machine: Through multiple rolling processes, the material is transformed into the shape of glazed tiles. ↓ Post-cut to length (hydraulic): Cut the finished product to the specified length according to demand. ↓ Output manual support/stacker (optional): Transport the finished product out of the equipment.

This process is not only efficient, but also improves production accuracy through automation to ensure the quality of each glazed tile. |  |

Specific Features of Glazed Tile Roll Forming Machine

1

Feeding device

KINGREAL glazed tile making machine is equipped with an adjustable feeding device. The platform width can be adjusted by hand-wheel. The built-in bearing effectively protects the edge of the steel plate and ensures smooth material feeding.

2

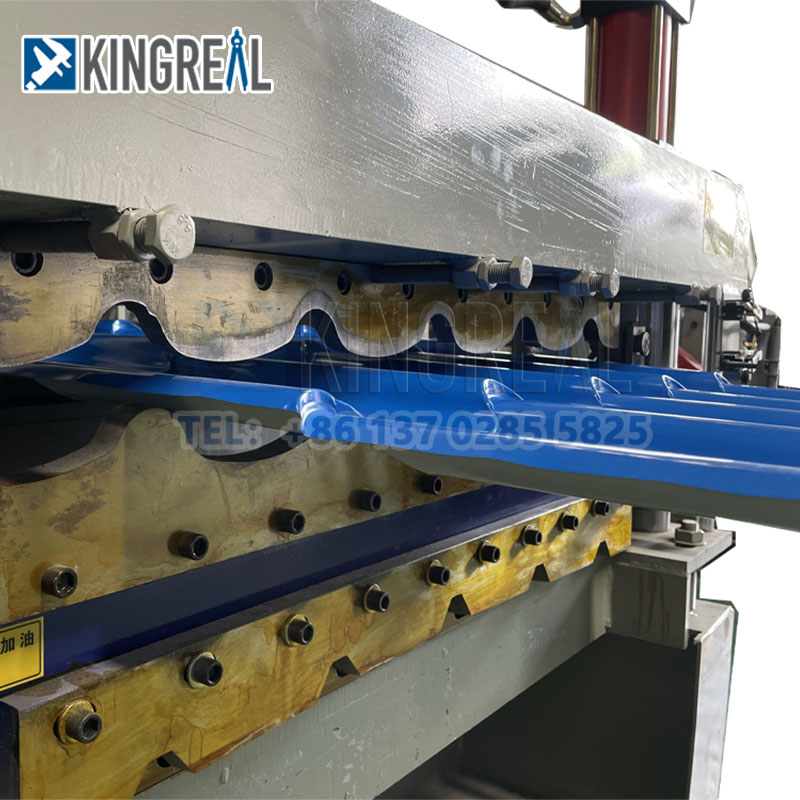

Rolling shaft and roller

The rolling shaft in the glazed tile roll forming machine is made of high-quality 40Cr steel with a shaft diameter of 80mm and tempered to prevent deformation and increase hardness. The roller is made of high-quality 45# steel and the surface is chrome-plated to increase surface smoothness, prevent wear and extend service life. The machine has 14 rolling stations and adopts a split rolling design to effectively release the internal stress of the plate and improve the shape and precision of the finished product.

3

Machine tool structure

The machine tool structure of the glazed tile making machine adopts a cast iron vertical arch frame. The basic frame uses hot-rolled H-shaped steel and is equipped with diagonal braces inside to enhance the structural strength. After overall welding, vibration welding is used to eliminate stress to ensure the horizontal and rigidity of the frame, thereby providing a more stable forming effect.

Main Functions of Glazed Tile Making Machine

Automatic forming Through multi-roller step-by-step pressing, the gearbox-type glazed tile roll forming machine can quickly process raw materials such as color steel plates and aluminum alloys into glazed tile shapes. Compared with traditional manual production, the production speed of automated forming can reach 20 m/min, meeting the needs of large-scale industrial production. |  |

Enhanced waterproof performance During the forming process, the glazed tiles produced by automated production can ensure that the tiles fit closely together, thereby greatly improving the waterproof performance. Through precise pressing and forming, the surface of the tiles is smoother, effectively reducing the possibility of rainwater infiltration. |  |

Improved durability KINGREAL glazed tile making machine ensures the uniformity of materials and structures during the automated production process, thereby improving the durability and wind resistance of the product. This glazed tile can better resist the erosion of bad weather and extend its service life. |  |

Wide range of applications The glazed tiles produced by this glazed tile roll forming machine are suitable for various building scenarios, including personal residences, villas, industrial plants, park squares, and ancient building restoration. Its products not only have good decorative effects, but also meet practical functions such as building waterproofing, heat preservation, and heat insulation. |  |