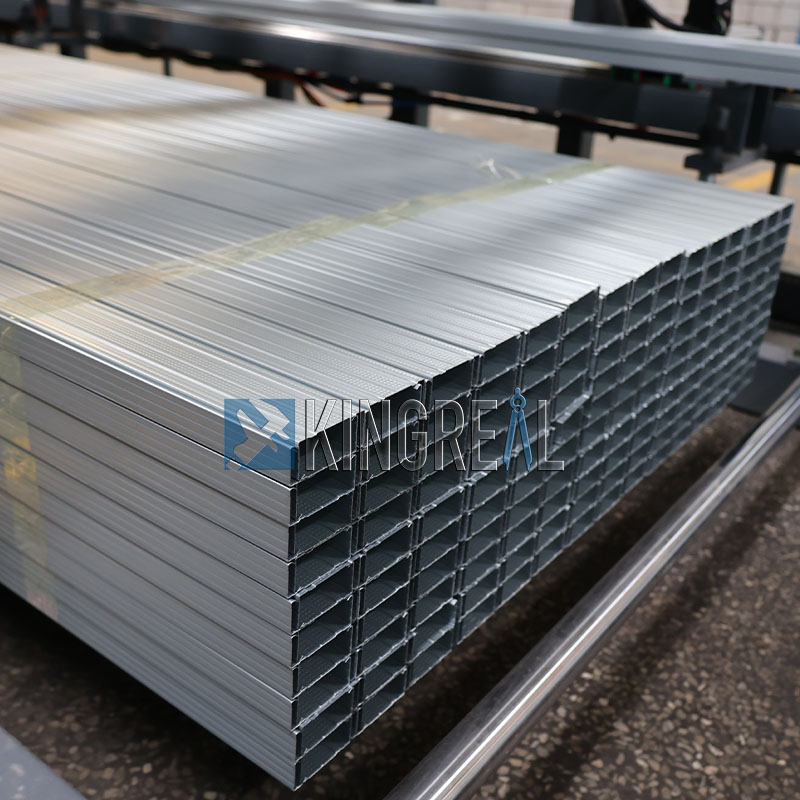

Producing Drywall Profiles: The Coil To Pack System

2025-09-25 12:00KINGREAL Coil to Pack System is an essential component of high-speed drywall profile machine and false ceiling channel machine. This coil to pack system not only improves production efficiency but also ensures the quality of the finished product. This article will provide a detailed introduction to the various components of the Coil to Pack System and their integration with the drywall profile machine and false ceiling channel machine, demonstrating its crucial role in improving production efficiency.

01/Introduction to the Coil to Pack System

The Coil to Pack System is an integrated system for the automated packaging of drywall profiles processed from coils. The coil to pack system comprises seven key stages: feeding, fastening, stacking, wrapping, pulling, palletizing, and electronic control. The efficient coordination of these stages streamlines the entire production process.

-Feeding stage for coil to pack system

The feeding stage is the first stage of the coil to pack system and utilizes variable frequency drive with adjustable speed. This stage utilizes a four-layer, multi-grid, non-slip belt to ensure profile stability during transport. The push cylinder features a rubber-coated soft-tip design to effectively prevent scratches on the studs during transport. This design lays a solid foundation for subsequent production processes.

-Clipping section for coil to pack system

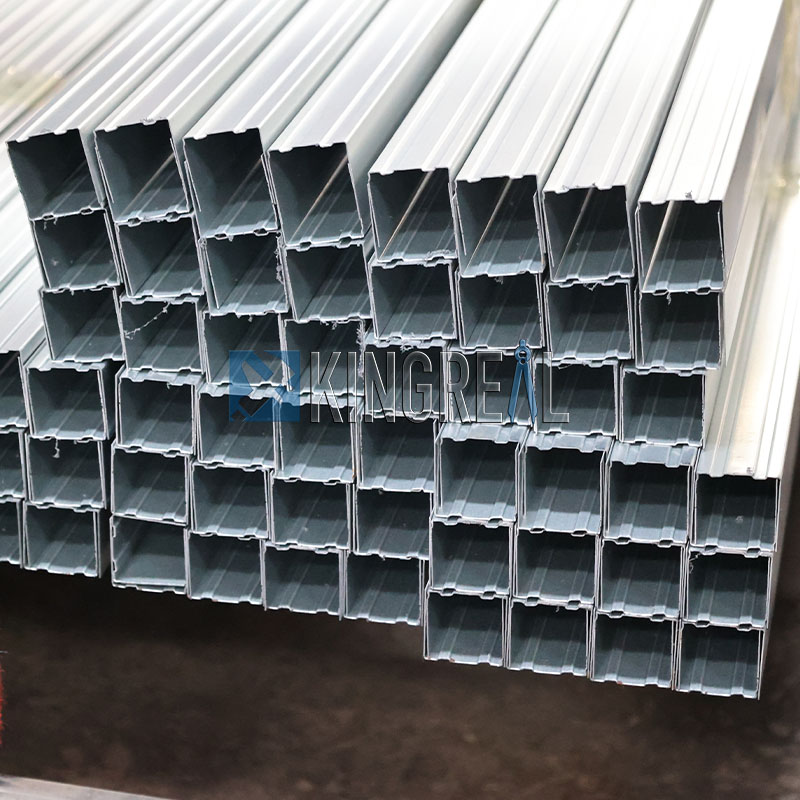

The clipping section is a crucial component of the coil to pack system. It utilizes servo control, boasts a simple yet durable structure, and requires virtually no maintenance. When two drywall profiles arrive simultaneously, the clipping plate rotates, driving the first drywall profile to clip onto the second. This efficient clipping mechanism makes the entire production process faster and smoother.

-Stacking section for coil to pack system

The stacking section utilizes a screw drive, ensuring high precision and accurate stacking of the profiles. The upper drive shaft is fully protected, effectively eliminating safety hazards and providing a safe working environment for workers.

-Wrapping section for coil to pack system

The wrapping section is also designed with precision and safety in mind. The stability of the servo drive system ensures reliable and durable wrapping. Wallpaper blades are used in the cutting process, making them easy to replace and cost-effective. The fixed shaft uses a hexagonal shaft to effectively prevent the tape from slipping, and the tape tension is adjustable to ensure no loosening during the wrapping process. Furthermore, the drywall profile alignment clamps feature a soft rubber coating to prevent scratches on the drywall profiles during wrapping.

-Material pulling section for coil to pack system

The material pulling section utilizes a servo rack-and-pinion drive, suitable for high-speed, long-distance movement. The material clamping section also utilizes a soft rubber coating to prevent damage to the pallet. The adjustable pressure of the air cylinder ensures that even pallets as thin as 0.3mm are not squeezed, ensuring compatibility with pallets of various sizes.

-Palletizing section for coil to pack system

In the palletizing section, all profiles are heavy-duty. The palletizing pallet is bent, not welded, to eliminate the risk of weld splitting or breakage. Furthermore, the base is constructed of 120*80 square tube, providing a more stable support and facilitating forklift operation. Heavy-duty drag chains are used for stability even under long-duration operating conditions.

-Electrical control section for coil to pack system

The electronic control section utilizes six Delta servo systems, covering functions such as fastening, lifting and stacking, tape wrapping, material pulling, pallet translation, and pallet lifting. This servo system is more stable than stepper motors and air cylinders in long-term or high-speed production environments. The system is simple to operate with one-touch operation and can store 50 pallet type recipes for quick switching.

02/High Speed Drywall Profile Machine & Coil To Pack System

KINGREAL high-speed drywall profile machines, combined with the Coil To Pack System, enable a series of operations, including high-speed snap-fitting, lifting, stacking, and tape wrapping. This efficient production capability ensures that customers' requirements for various profile specifications are met.

Through close collaboration with customers, KINGREAL is able to customize the Coil To Pack System based on their specific production needs, ensuring that the system is perfectly adapted to the profiles produced by the drywall profile machine. This coil to pack system not only improves production efficiency but also enhances the quality of the finished product, giving customers a competitive advantage in the market.

03/False Ceiling Channel Machine & Coil To Pack System

KINGREAL false ceiling channel machines, included main channel making machine, drywall wall angle profile machine, and hat channel machine, can also be integrated with the Coil To Pack System, significantly improving production efficiency. The coil to pack system’s automated design effectively reduces labor costs and enhances production efficiency. The Coil To Pack System's adjustable operating table facilitates ease of use for operators of varying heights, while also providing excellent visibility and enhancing work comfort and safety. This user-friendly design not only improves work efficiency but also enhances employee satisfaction.

04/KINGREAL Comprehensive Solutions

KINGREAL is committed to providing customers with complete solutions, covering every step of the process, from production and cleaning to bundling, labeling, and stacking. The Coil to Pack System, combined with the drywall profile machine and false ceiling channel machine, not only optimizes workflows but also improves production quality and efficiency.

KINGREAL machines and services have been widely recognized in collaboration with customers worldwide, including in Kazakhstan, Turkey, Qatar, and Mexico. KINGREAL consistently delivers a superior customer experience, whether in efficient production, equipment maintenance, or customer service.

The combination of the Coil to Pack System and the drywall profile machine or false ceiling channel machine, significantly improves the production efficiency and quality of drywall profiles in the construction industry. With this system, KINGREAL not only automates the production process but also ensures precise packaging and stacking of drywall profiles.

If you are interested in the drywall profile machine or false ceiling channel machine and the Coil to Pack System, please feel free to contact us. KINGREAL is dedicated to providing professional services and solutions to meet your production needs.