What are the advantages of the c purlin roll forming machine?

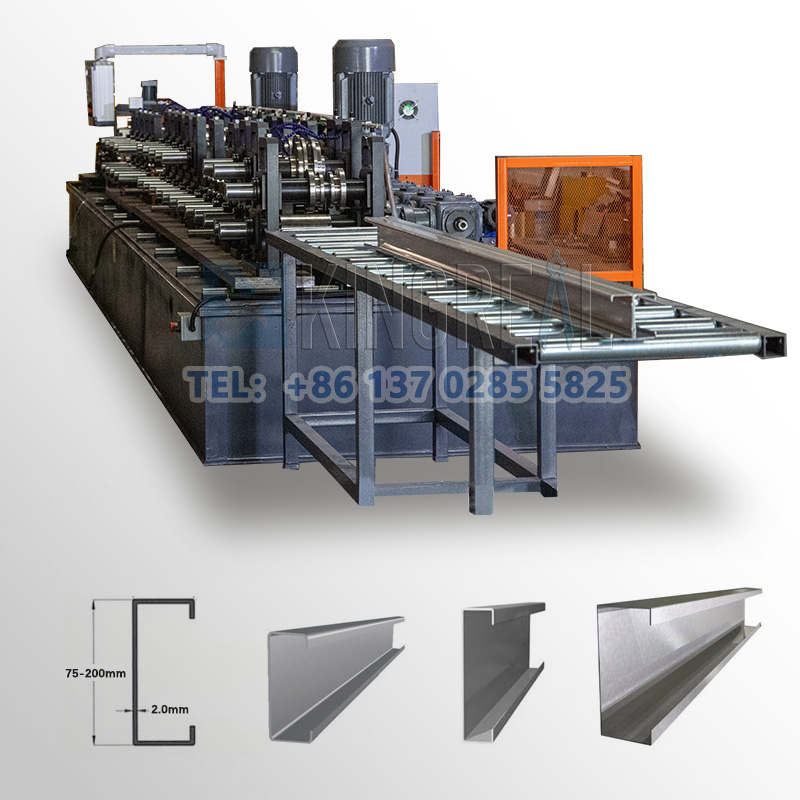

2025-07-18 12:00C purlin roll forming machine is a kind of equipment used to continuously produce c purlin by passing galvanized or cold-rolled steel strip through a series of processes such as feeding, punching, bending, cutting, etc. The profiles produced by this c purlin machine have a C-shaped cross-section and are mainly used for roof and wall joists in building shell structures. Due to its light weight, easy installation and transportation, c purlins are widely used in the construction industry, especially in large warehouses, industrial plants and commercial buildings. This article will discuss the working process, technical parameters and many advantages of c purlin roll forming machine in detail. |  |

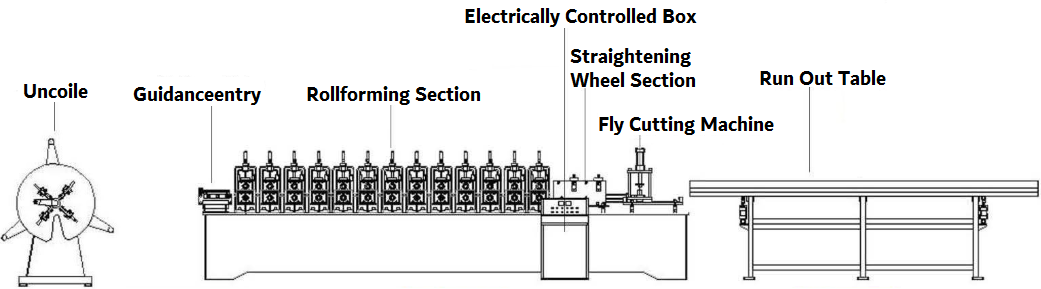

Working Process of C Purlin Machine

Decoiler →Leveling Machine→ Feeding System→ Punching Unit→ Pre-cutting Die→ Roll Forming Machine→Output Table

Parameter of C Purlin Roll Forming Machine

| Total Power | 11-18KW |

| Speed | 18m/min |

| Roller Station | 14-20 |

| Material Width | 1.0-3.0mm |

| Transmission System | 150-450mm |

| Cutting System | Hydraulic motor |

| Punching System | Hydraulic cylinder (rear & front cutting) |

| Changing Size | Manual with spacers |

| Control System | Automatic with PLC, HMI |

Advantages of C Purlin Machine

1. Fully automated c purlin roll forming machine

This c purlin machine uses inverter, PLC and HMI for automatic roll forming and cutting, and users can easily set the required length and specifications through the touch screen. This design can significantly reduce labor costs, improve production efficiency and production quality, especially in large-scale production, the advantages of automated c purlin roll forming machines are more obvious.

2. Stable c purlin machine operation

The stability of the c purlin roll forming machine directly affects the production efficiency and product quality. The rollers and blades of the c purlin machine are made of alloy steel and SKD11 steel with a hardness of 60-62HRC, ensuring its durability and stability under high-intensity operation.

In addition, the electrical and hydraulic components are mainly sourced from Japan and Germany. These high-quality components together constitute the powerful power system and stable body frame of the c purlin roll forming machine, thereby ensuring the smooth operation of the c purlin machine.

3. Personalized c purlin machine customization plan

KINGREAL provides customers with personalized c purlin roll forming machine manufacturing plans, allowing customers to customize the color, component performance and parameters of the c purlin machine according to actual production needs. This flexibility enables the c purlin roll forming machine to adapt to a variety of different production environments and needs, enhancing its market competitiveness.

4. Energy-saving and efficient c purlin machine

The design of the c purlin roll forming machine fully considers energy-saving factors. The use of inverters to control the operation of the motor can reduce energy consumption while ensuring production efficiency.

In addition, the c purlin machine’s efficient production capacity has greatly reduced the energy consumption per unit of product, which meets the requirements of modern industry for sustainable development.

5. High precision of finished products

The profiles produced by the c purlin roll forming machine have high precision and stable quality. Thanks to its advanced punching and cutting system, the size and hole position of the product can be precisely controlled, ensuring that the finished product can meet the strict standards of the building structure. This high-quality product further enhances customers' trust in the c purlin machine.

6. Easy-to-maintain c purlin machine

The design of the c purlin roll forming machine takes into account the later maintenance and care. All parts of the c purlin machine can be quickly disassembled, replaced and repaired, making the maintenance process simple and efficient.

In addition, the high degree of automation of the c purlin roll forming machine reduces manual intervention and reduces the failure rate.

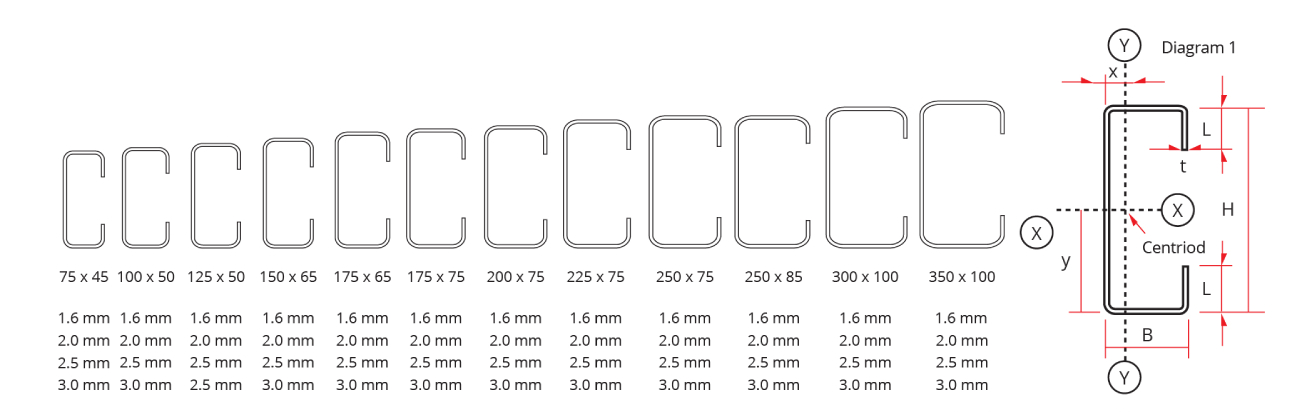

Common Parameters of C Purlin

| Size | A | B | C | t | Coil Width |

| C100 | 100 | 40-50 | 16-22 | 1.2-2.4 | 200-221 |

| C125 | 125 | 40-50 | 16-22 | 1.2-2.4 | 225-246 |

| C150 | 150 | 45-70 | 16-22 | 1.2-2.4 | 260-311 |

| C175 | 175 | 50-75 | 16-22 | 1.2-2.4 | 295-346 |

| C200 | 200 | 50-80 | 16-22 | 1.2-2.4 | 320-381 |

| C250 | 250 | 50-80 | 16-22 | 1.2-2.4 | 370-431 |

| C300 | 300 | 60-100 | 16-22 | 1.5-3.2 | 437-513 |

| C350 | 350 | 60-100 | 16-22 | 1.5-3.2 | 487-563 |

Application of C Purlin Machine

√Supporting roof sheeting and wall cladding.

√Spanning between rafters or wall studs.

√Transferring loads to the primary structural frame.

Advantages of C Purlins

High durability: c purlins are far more durable than conventional materials like wood, resisting decay and withstanding severe storms and environmental circumstances.

Although c purlins have outstanding loadbearing capacity, they are comparatively light, so lowering the whole load on the construction.

C purlins are precisely made to conventional sizes, hence are simple to carry and put up with little effort.

High aesthetics: The surface of this product is smooth; it fights rust and distortion; and it keeps its beauty for a long time.

C purlins with great loadbearing capacity and extended lifetime help lower during use maintenance and replacement expenses.