What is grilyato ceiling machine?

2025-07-13 12:00"The grilyato ceiling machine usually processes iron plates with a thickness range of 0.25-0.4mm or aluminum plates with a thickness range of 0.3-0.4mm into various types of open cell ceilings required by customers, such as U-shaped grilyato ceilings, C-shaped grilyato ceilings and pyramid grilyato ceilings. The common sizes of grilyato ceilings produced by these open cell ceiling machines are 25X25MM, 30X30MM, 38X38MM, 50X50MM, 65X65MM, which are open and flexible. This grilyato ceiling machine is efficient and stable at a speed of 30m/min."

1/Workflow of Open Cell Ceiling Machine

Hydraulic Decoiler-- Precision Straightener -- Perforation Press -- Cut-to-length Press Machine -- Main Roll Forming Machine -- Product Table

2/Grilyato Ceiling Machine Suitable Material Specification

Material:GI STEEL,ALUMINUM,PRE-PAINTED GI STEEL

Material Thickness:0.25-0.4mm

Profile Size: U15x37/U15x47mm(Main &Cross)

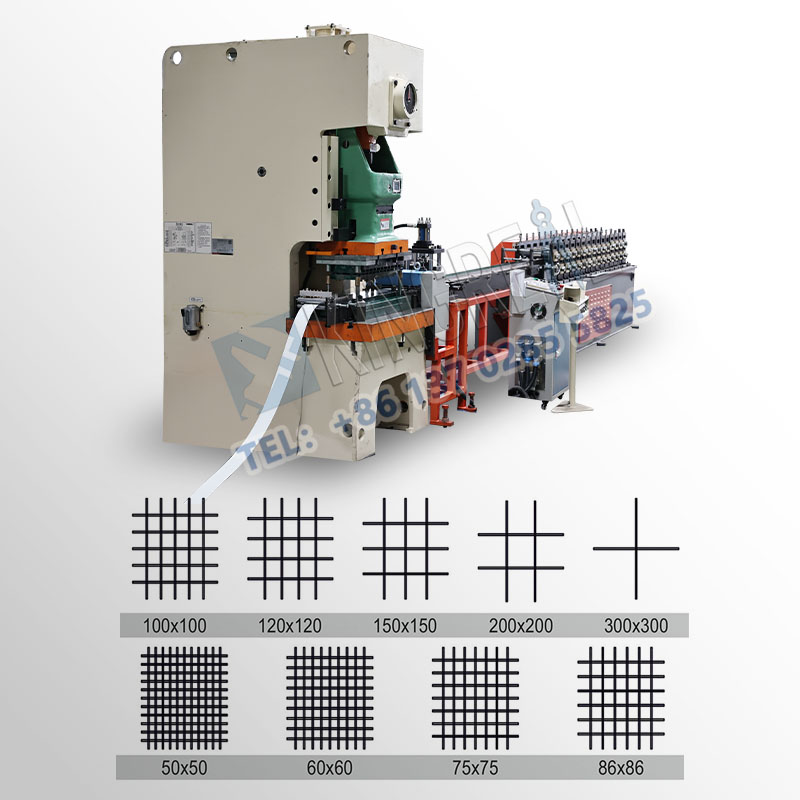

Punching Distance:50/60/75/86/100/120/150/200mm

Production Speed:30m/min

3/Technical Data of Open Cell Ceiling Machine

Forming Steps: about 15 stations

Material of Roller: Cr12Mov

Roller’s Hardness:HRC58-60 Degrees

Driven system: Gearbox driven

Power supplier: 380V, 50 Hz, 3Phases, according to customer's requirements

The whole grilyato ceiling machine is controlled by PLC.

4/Features for Open Cell Ceiling Machine

Efficient Punching Speed for grilyato ceiling machine

The grilyato ceiling machine has fast punching capability and can complete mass production tasks in a short time. The grilyato ceiling making machine also demonstrates excellent precision during the punching process, ensuring that the aperture and size of each product meet the design standards. The finished product has strong consistency, avoiding errors in production and improving the quality stability of the product.

Material compatibility for grilyato ceiling machine

The open cell ceiling making machine is compatible with both aluminum and iron materials to meet different production needs. This versatility makes the grilyato ceiling machine have a wide range of application prospects in a diverse market environment.

Precision cutting for open cell ceiling machine

With the help of advanced cutting technology, the grilyato ceiling machine can achieve high-precision cutting to ensure the appearance and quality of the product. Precision cutting not only improves the aesthetics, but also enhances the practicality of the product.

Meet customer needs

With the growing market demand for open cell ceilings of different types and specifications, the flexibility and adaptability of the grilyato ceiling machine are particularly important. The open cell ceiling machine can adjust the cutting parameters according to the specific requirements of the customer to produce grilyato ceilings that meet various specifications.

5/Different Open Cell Ceiling Machine Manufacturing Solutions

KINGREAL is good at providing customized grilyato ceiling machine manufacturing solutions based on the actual production needs of customers and combined with drawings. Therefore, the parameters, performance and components of the open cell ceiling machines manufactured by KINGREAL are not exactly the same. At the same time, KINGREAL can also sell other roll forming machines together to provide customers with a complete grilyato ceiling solution. The following is a special open cell ceiling machine manufacturing solution:

Equip the grilyato ceiling machine with perforation press of different tonnages.

KINGREAL has designed two different perforation presses for the open cell ceiling machine, one is a 16-ton perforation press and the other is a 63-ton perforation press. The 16-ton perforation press is equipped with a standard grilyato ceiling machine, with a stroke of 150 times/min, a stroke distance of 50mm, a maximum closure height of 250mm, and a worktable dimension of 1500x680mm. The 63-ton perforation press is designed by KINGREAL engineers for high-end open cell ceiling machines. It can complete punching in one go without stopping the grilyato ceiling machine. This can improve production efficiency and punching accuracy.

Open cell ceiling machine with protective shield.

In order to meet customers' needs for production safety and meet the high requirements of some countries for machine safety performance, KINGREAL engineers proposed that the grilyato ceiling machine can be equipped with a protective shield. When the open cell ceiling machine is running, the protective shield will cover the roll forming machine. When the grilyato ceiling machine is not running, the protective shield can be opened to maintain and clean the inside of the roll forming machine, which is very convenient.

Open cell ceiling machine with ceiling t bar machine.

The open cell ceiling produced by the open cell ceiling machine can be used with the main and auxiliary ribs produced by the ceiling t bar machine to form a grilyato ceiling with ceiling t bar system. Each open cell ceiling is inserted into different modules according to the required style, and finally the assembled modules are placed on the suspension system formed by the ceiling t bar to form a complete grilyato ceiling system with a modular structure.

6/Comprehensive Support Throughout Your Open Cell Ceiling Machine Purchase Journey

Accompanying factory visits

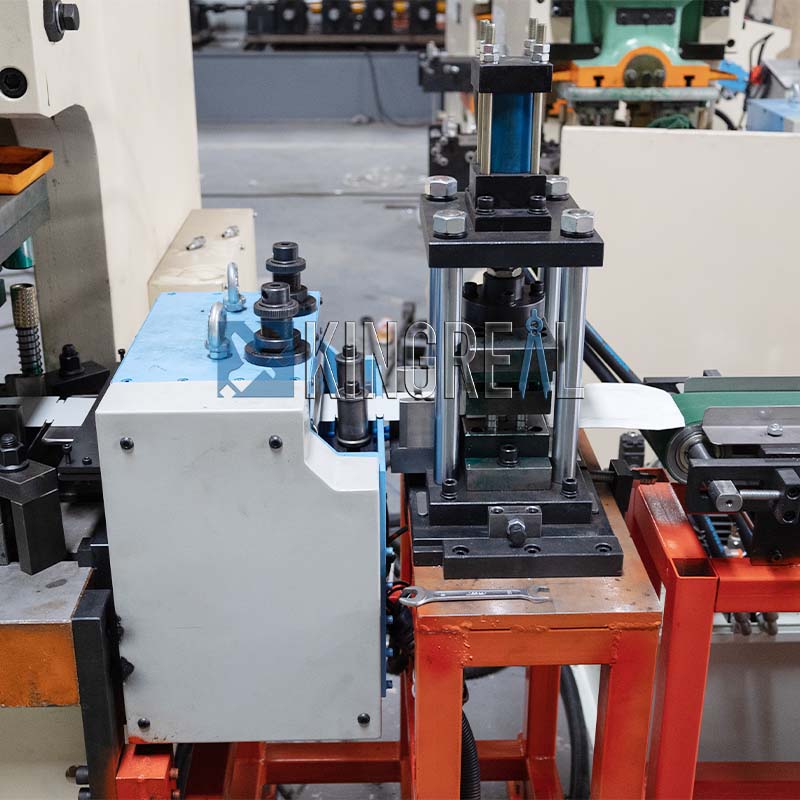

KINGREAL has warmly welcomed customers from different countries to visit the KINGREAL factory to visit the grilyato ceiling machine and verify whether the machine meets the customer's production needs through on-site inspections. In the factory, KINGREAL will give a detailed introduction to the important components of the open cell ceiling machine such as the decoiler, leveler, perforation press, cutting station, roll forming machine, etc. In addition, KINGREAL will invite customers to test the finished products produced by the grilyato ceiling machine, so that customers can have a deeper understanding of KINGREAL open cell ceiling machines.

Machine inspection

When the grilyato ceiling machine is manufactured, KINGREAL will invite customers to the factory to personally inspect the open cell ceiling machine. If the customer is sometimes unable to visit the site, KINGREAL will hold an online meeting and have KINGREAL staff commission a grilyato ceiling machine test. Customers can see the entire test process in real time. Only when the machine parameters and performance meet the promises in the plan and the customer's delivery permission is obtained, the open cell ceiling machine will be arranged for delivery.

Grilyato ceiling machine installation

When the open cell ceiling machine is delivered to the customer's factory, KINGREAL engineers will go to the customer's factory to install the grilyato ceiling machine. This includes checking the status of each component and assembling it into a complete production line. Putting metal coils into the open cell ceiling machine for startup testing, adjusting parameters for testing, etc. KINGREAL has a complete grilyato ceiling machine installation process.

Open cell ceiling machine operation training

KINGREAL engineers will provide grilyato ceiling machine operation training to workers, including how to turn on and off the grilyato ceiling machine, how to adjust production parameters on the control panel, etc.