How to choose roll forming machine?

2025-07-08 12:00Roll forming machines are essential equipment in sheet metal processing. They can process a variety of metals such as steel, aluminum, stainless steel and copper, and process flat metal sheets into various profiles and shapes. They are ideal for industries such as construction, automotive and HVAC. However, faced with a wide range of options on the market, how do you choose the most suitable roll forming machine? In this article, KINGREAL will discuss with you to help you make an informed decision that meets your specific needs.

1. Clarify Your Needs

Before choosing a roll forming machine, you must first clarify your needs: what finished product do you want to produce? What is it used for?

KINGREAL can provide a variety of roll forming machines to meet the needs of customers in different industries, and can provide customers with a full set of solutions. The following are KINGREAL's featured roll forming machines:

metal roofing machine, ibr roof sheet making machine, glazed tile roll forming machine, trapezoidal sheet roll forming machine, standing seam roof panel machine...

unistrut channel roll forming machine, pv support bracket machine

upright rack making machine, shelf panel machine, box beam machine, step beam machine...

hat channel machine,corner bead machine, u channel machine, drywall profile machine...

2. Machine components of roll forming machine

Machine components determine the stability, efficiency and finished product accuracy of production. Each roll forming machine of KINGREAL can be customized for the parameters and performance of the components. This article introduces different solutions for the decoiler, leveling machine, main roll forming machine and cutting station commonly equipped in the roll forming machine.

2.1 Decoiler for roll forming machine

The decoiler is an important component of the roll forming machine. It is mainly used to stretch the large roll of metal coils for subsequent processing. According to the production needs of customers, KINGREAL can provide decoilers with different performances.

2.1.1 Single-head decoiler Single-head decoiler is a passive decoiler that usually cannot feed independently, so it is generally used in conjunction with a feeder. Its structure is relatively simple and suitable for occasions where the production scale is not high. The advantage of a single-head decoiler is that it is low-cost and suitable for start-ups or small production lines. |  |

2.1.2 Double-head decoiler The double-head decoiler is equipped with two reels, which can achieve more efficient material alternating uncoiling. While the left reel is unwinding, the right reel is feeding. When the material on the left is used up, just turn the decoiler 180° to continue unwinding. This design significantly improves production efficiency, especially for production scenarios where material rolls need to be frequently replaced. |  |

2.1.3 Hydraulic decoiler The hydraulic decoiler uses hydraulic expansion to provide a stable solution, which can ensure the tension and smooth unfolding of the material roll. The equipment can not only expand and shrink automatically, but also has the function of active feeding, which greatly improves the convenience and safety of use. Hydraulic decoilers are usually used in larger-scale production lines and can effectively cope with higher production requirements. |  |

2.1.4 2-in-1 decoiler and leveling machine To save space and achieve more efficient production, KINGREAL also provides 2-in-1 decoiler and leveling machines. This equipment combines the functions of unwinding and leveling, and can complete two tasks in one device, reducing the footprint of the equipment while improving production efficiency. It is very suitable for production environments with limited space. |  |

2.2 Leveling machine for roll forming machine

The main function of the leveling machine is to level the metal coil to ensure the accuracy in the subsequent forming process. The effect of the leveling machine is closely related to the diameter and number of layers of the roller.

2.2.1 Design of the leveling machine Usually, KINGREAL equips customers' roll forming machines with a two-high leveling machine. This design effectively removes the waves and distortions of the coil through the cooperation of multiple rollers, ensuring its stability and accuracy during the forming process. If the customer has extremely high requirements for leveling, KINGREAL can also provide four-high leveling machines and six-high leveling machines to meet more stringent production standards. |  |

2.2.2 Leveling effect and roller design The smaller the diameter of the roller and the more layers, the better the leveling effect is usually. The multi-layer roller can flatten the coil under different pressures to achieve the desired effect. This design is especially important when dealing with thick metal materials, which can effectively avoid deformation of the material during the forming process. |  |

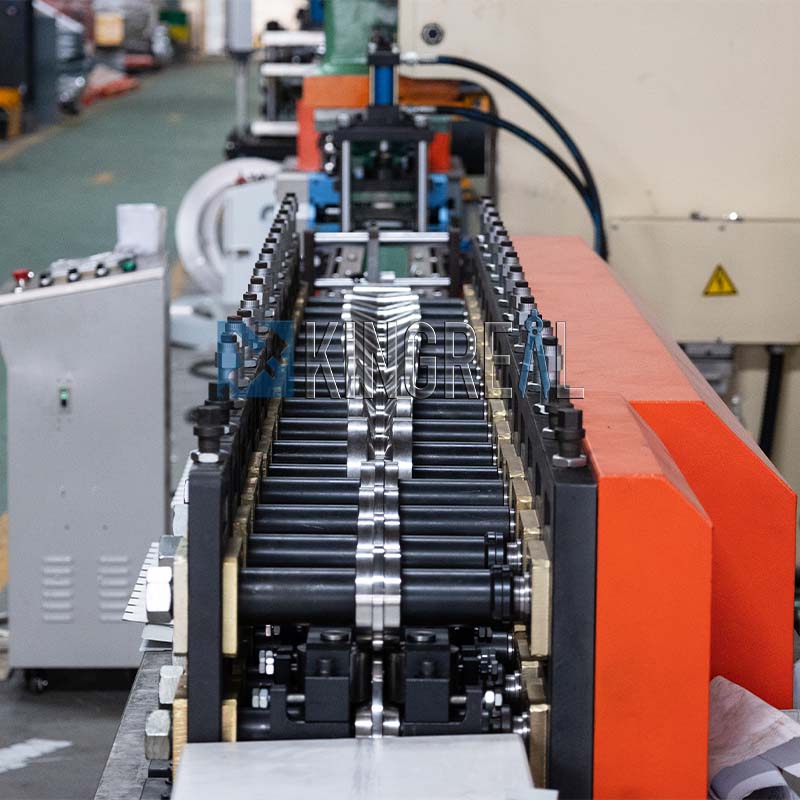

2.3 Main roll forming machine for roll forming machine

The main roll forming machine is the most important component in the roll forming machine, responsible for processing the metal coil into the finished product shape required by the customer.

2.3.1 Single-specification and multi-specification roll forming machines KINGREAL has designed two kinds of roll forming machines according to customer needs. The single-specification roll forming machine can only produce finished products of one size, which is suitable for customers with relatively single production needs. The multi-specification roll forming machine allows users to automatically adjust the width of the roller by modifying the parameters on the control panel, thereby producing finished products of different sizes. This flexibility meets the customer's diverse needs for finished product specifications. For example, KINGREAL can provide multi-specification roll forming machine manufacturing solutions for drywall profile machines, baffle ceiling machines and open cell ceiling machines. |  |

2.3.2 Selection of roller materials In the manufacturing of roll forming machines, the selection of roller materials is crucial. KINGREAL's commonly used roller materials include CR12Mov, CR12, 45#, Gcr15 and 42CrMo. The hardness and wear resistance of these materials directly affect the quality and service life of the forming. The thickness of different metal raw materials will also affect the selection of rollers, so when customers customize, KINGREAL will provide professional advice to ensure the best performance of the roll forming machine. |  |

2.3.3 Produce finished products with brand logos In order to enhance the market competitiveness of finished products, KINGREAL has also designed a roll forming machine that can meet customers' needs to produce finished products with logos. There are two main options: one is to equip the roll forming machine with an inkjet device to print the customer's brand logo on the surface of the finished product during the production process; the other is to engrave the customer's brand logo on the roller surface of the roll forming machine, so that finished products with brand logos can be produced during the forming rolling process. This provides customers with greater flexibility and brand recognition. |  |

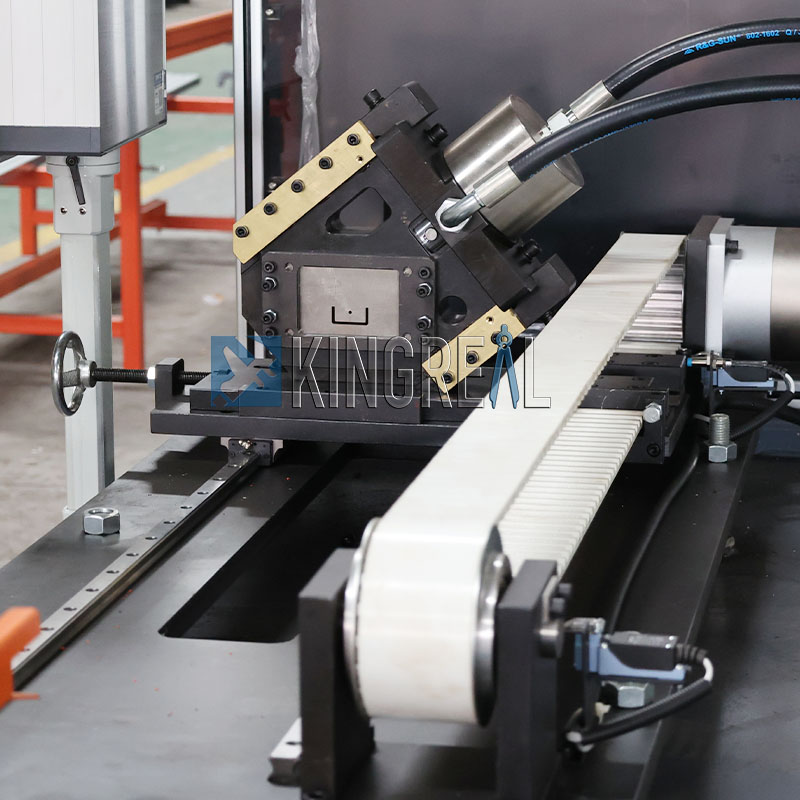

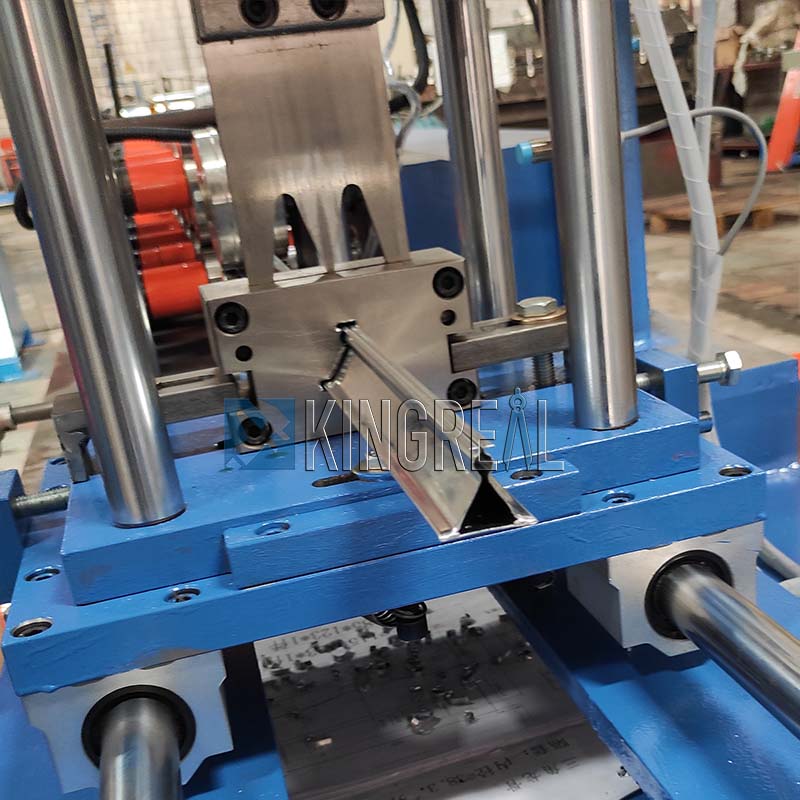

2.4 Cutting system for roll forming machine

The cutting system is an indispensable part of the roll forming machine, which is mainly used to shear the formed metal material into the required length. According to the different shearing speeds, KINGREAL divides the shearing methods into flying shearing, following shearing and fixed shearing.

2.4.1 Flying shear for roll forming machine The speed of flying shear is usually above 60m/min, which is suitable for large-scale production needs. This shearing method can complete the shearing task at high speed, ensuring production efficiency and finished product quality. Flying shear system is widely used in occasions that require fast cutting, such as main ceiling channel machine, etc. |  |

2.4.2 Follow shearing for roll forming machine The speed of follow shearing system is between 30-60m/min, and the specific speed needs to be designed according to the actual production situation of the customer. This shearing method can perform synchronous shearing according to the rhythm of the roll forming machine, which is suitable for enterprises with medium production scale. Equipment such as linear strip ceiling machines usually use follow shearing system to achieve good production efficiency and cost control. |  |

2.4.3 Fixed shearing for roll forming machine The speed of fixed shearing is relatively slow, usually below 30m/min, which is suitable for customers with low requirements for production efficiency. This shearing method is suitable for small batch production or occasions with high requirements for shearing accuracy. |  |

3. After-sales service

When selecting a roll forming machine, in addition to the quality of the equipment, the after-sales service provided by the manufacturer is also very important. KINGREAL provides detailed after-sales service. After the roll forming machine is manufactured, KINGREAL will send professional engineers to the customer's factory to install the equipment and provide machine operation training to the workers. They will carefully explain to customers how to maintain the equipment on a daily basis. If a machine failure occurs, KINGREAL will find the cause of the machine failure and solve it as quickly as possible through offline or online videos.

KINGREAL hope that this article can give you the direction of selecting a roll forming machine. If you are interested in a certain type of equipment, please feel free to contact KINGREAL!