What is a perforated metal machine used for?

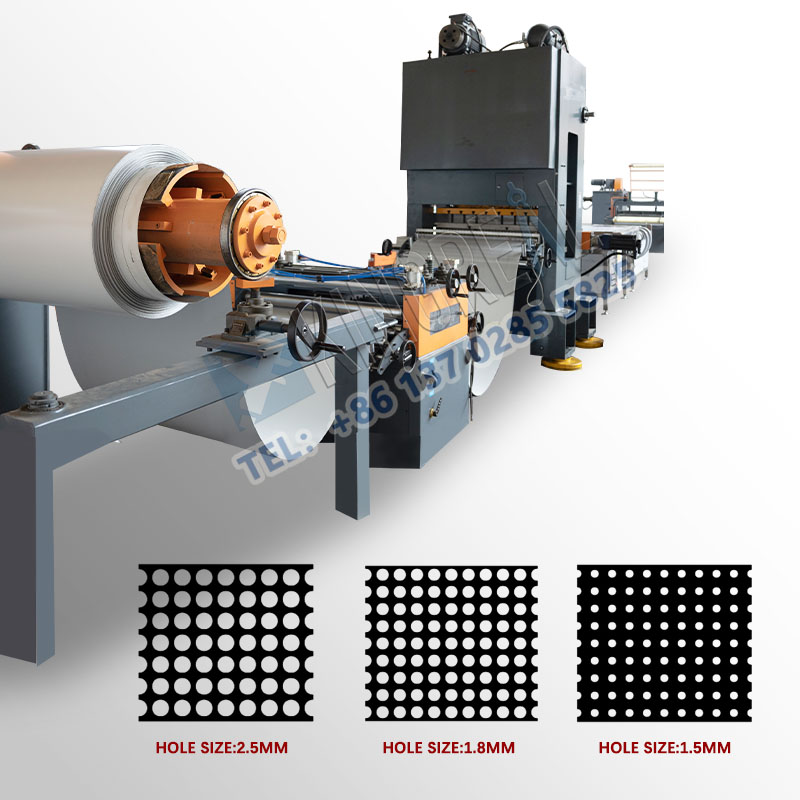

2025-07-06 12:00| Perforated metal machine is a special equipment used to punch out different hole types and hole diameters on metal coils. In order to meet the diverse needs of customers in production processes, KINGREAL has designed a variety of metal perforating machines, such as metal ceiling tile perforation lines, coil to coil perforation lines and sheet metal perforating machines. If you are interested in these perforated metal machines or need more information, please come to consult KINGREAL! We have a wealth of project cases and special metal perforating machine manufacturing solutions, and we are happy to share them with you. |  |

Workflow of Metal Perforating Machine

1. Uncoiling for perforated metal machine The first step in the production process is to unwind the metal coil. This step is performed by the decoiler to ensure that the metal material can enter the subsequent process smoothly. The decoiler can handle metal coils of various widths and thicknesses, ensuring that the material is continuously and stably transferred to the leveling stage. |  |

2. Leveling for metal perforating machine The uncoiled metal coil may have corrugations or unevenness, so it needs to be processed by the leveling machine. The leveling machine flattens the surface of the metal material through mechanical force to eliminate any defects that may affect the accuracy of subsequent punching. |  |

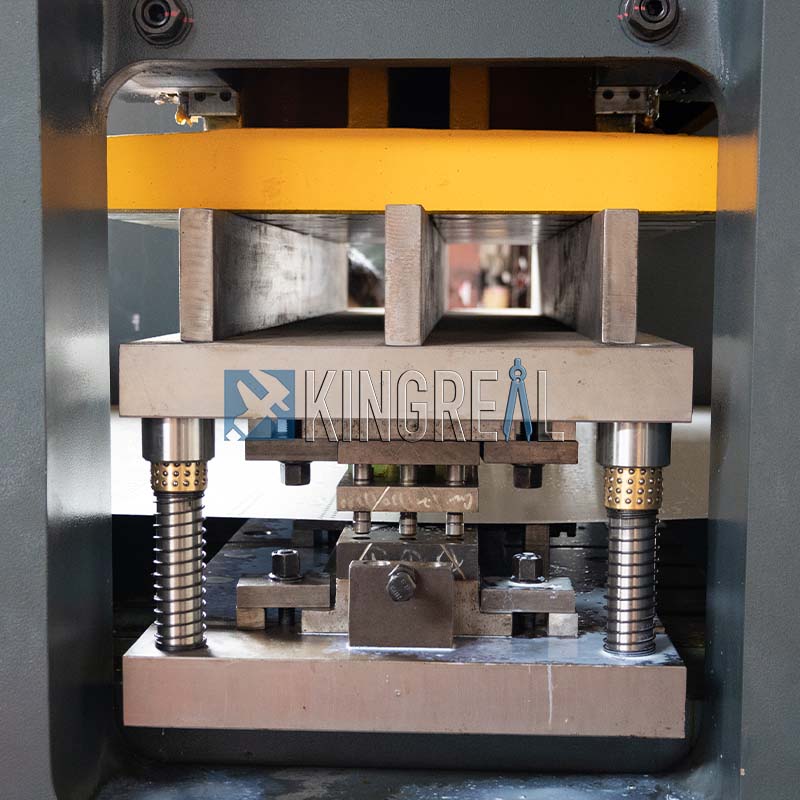

3. Punching for perforated metal machine The punching step is the most critical step in the entire production process. At this stage, KINGREAL designs punching dies with specific hole shapes according to customer needs. These dies can produce holes of various shapes and sizes. The metal perforating machine shows the characteristics of high precision and fast production in this process, ensuring that while ensuring product quality, production efficiency is greatly improved. |  |

4. Cutting or Recoiling for perforated metal machine The perforated metal coils usually need to be precisely cut through sheet metal perforating machine to ensure that each finished product meets the customer's specifications. Alternatively, the perforated coils can be reeled through coil to coil perforation line for subsequent storage and transportation. The use of a coil to coil perforation line not only facilitates the storage of materials, but also effectively protects the surface from scratches or other damage during transportation. |  |

5. Quality Inspection All products produced by the perforated metal machine will undergo strict quality inspections, including hole size inspection, plate flatness inspection, and surface treatment quality inspection. This series of quality control links ensures that each perforated plate meets customer needs and industry standards, ensuring product reliability. |  |

Application of Metal Perforating Machines

1. Perforated metal machine in construction and decoration

Metal perforating machines are widely used in the fields of construction and decoration. It can produce finished products such as building curtain walls, ceilings, balcony guardrails, stair treads, and partition screens. These punching products not only increase the beauty of the building, but also improve its practicality. For example, perforated ceilings can not only beautify the indoor environment, but also effectively cover wires and pipes while maintaining good ventilation.

2.Perforated metal machine in industry and machinery

In the field of industry and machinery, the perforated plates produced by metal perforating machines are often used to make protective covers, ventilation and heat dissipation plates, filters and screens for various mechanical equipment. These products can effectively protect the equipment and ensure its safe operation and efficient work. Especially in high temperature or high pressure environments, good heat dissipation is essential. The design of the perforated plates can meet this demand and improve the durability of the perforated metal machine.

3. Metal perforating machine in food processing

Due to the corrosion resistance and easy cleaning characteristics of stainless steel materials, stainless steel perforated plates are widely used in the food processing industry. They are often used as food screening nets, washing baskets and baking racks to ensure the hygiene and safety of the food processing process. In the food industry, the safety and durability of materials are particularly important, and the application of perforated metal machines enables these needs to be met.

4. Metal perforating machine in chemical and pharmaceutical industries

In the chemical and pharmaceutical industries, the perforated plates produced by perforated metal machines are used to make various filtering devices, reactor liners and separators to ensure the efficiency and safety of chemical and pharmaceutical processes. These punching products can withstand high pressure and corrosive environments, ensure the durability and stability of metal perforating machine, and thus improve production efficiency.

5. Perforated metal machine in environmental protection and energy

Metal perforating machines also play an important role in the fields of environmental protection and energy. The perforated plates they manufacture can be used for water treatment filters, solar panel brackets, and wind power equipment protective covers. These products not only promote the development of green energy, but also contribute to sustainable development, reflecting the important value of modern punching technology in environmental protection.

Featured Perforated Metal Machine Manufacturing Solutions

1. Customized punching molds for metal perforating machine Whether it is round holes, square holes or special-shaped holes, KINGREAL can provide corresponding mold design and manufacturing according to customer drawing requirements. Such customized services ensure that customers can obtain punching products that meet their specific needs and improve production flexibility and efficiency. |  |

2. Metal perforating machine design to meet different process requirements KINGREAL has designed a variety of perforated metal machines, including metal ceiling tile perforation lines,coil to coil perforation lines, and sheet metal perforating machines. By matching with metal ceiling production lines, perforated ceilings of different sizes can be produced. The sheet metal perforating machine can produce punching sheets, which can be used to process and produce a variety of products such as punching filter screens, silencers, and screens. At the same time, the coil to coil perforation line can rewind the punched coils produced, which is convenient for subsequent processing such as bread trays and baffle ceilings. |  |

3. Punching machine configurations of different tonnages KINGREAL provides punching machines of various tonnages to meet the specific needs of customers in the production process. The tonnage of the punching machine is usually closely related to the following factors: The thickness of the metal raw material: Metal materials of different thicknesses require different impact forces to complete the punching. Thicker materials require a larger tonnage to ensure that the material can be effectively penetrated during the punching process, while thinner materials can use a relatively smaller tonnage machine. By accurately assessing the required material thickness, KINGREAL is able to recommend the most suitable punching machine configuration for customers to ensure the quality and efficiency of punching. The stroke required by the customer: The stroke refers to the distance the punch moves when the metal perforating machine is punching. Different product designs and hole type requirements will result in different required strokes. For example, larger or complex hole types may require a longer stroke, while standard hole types may only require a shorter stroke. KINGREAL will configure the appropriate perforated metal machine according to the customer's specific requirements and design drawings to ensure the accuracy and consistency of punching. Production efficiency requirements: Perforated metal machines of different tonnages also have differences in production efficiency. Larger tonnage metal perforating machines are usually able to withstand higher production loads and are suitable for long-term continuous operation, thereby improving production efficiency. Smaller tonnage metal perforating machines are more suitable for flexible and changeable production needs and can quickly adapt to different production tasks. According to the customer's production plan and efficiency goals, KINGREAL will provide the corresponding perforated metal machine configuration to help customers achieve the best production results. Process requirements and material types: Different process requirements and material types will also affect the tonnage selection of the metal perforating machine. For example, for high-strength alloy materials, a higher tonnage perforated metal machine may be required to ensure penetration. On the contrary, for aluminum alloys or other softer metals, lower tonnage machines can meet the needs. When communicating with customers, KINGREAL will understand their production processes and materials used in detail to ensure that the recommended equipment can achieve the best processing results. |  |