What is metal ceiling tile production line?

2025-05-19 12:00Metal ceiling tile production line is a combination of equipment specially used to produce various metal ceiling boards, which are widely used in the fields of construction, decoration and home furnishing. This metal ceiling making machine uses advanced mechanical equipment to process metal coils such as galvanized iron coils, aluminum coils and roll-coated coils through a series of processes to finally produce high-quality metal ceiling tiles. This article will give a detailed introduction to the composition, workflow, market demand and types of metal ceiling panels that the metal ceiling tile production line can produce.

1.Introduction to Metal Ceiling Making Machine

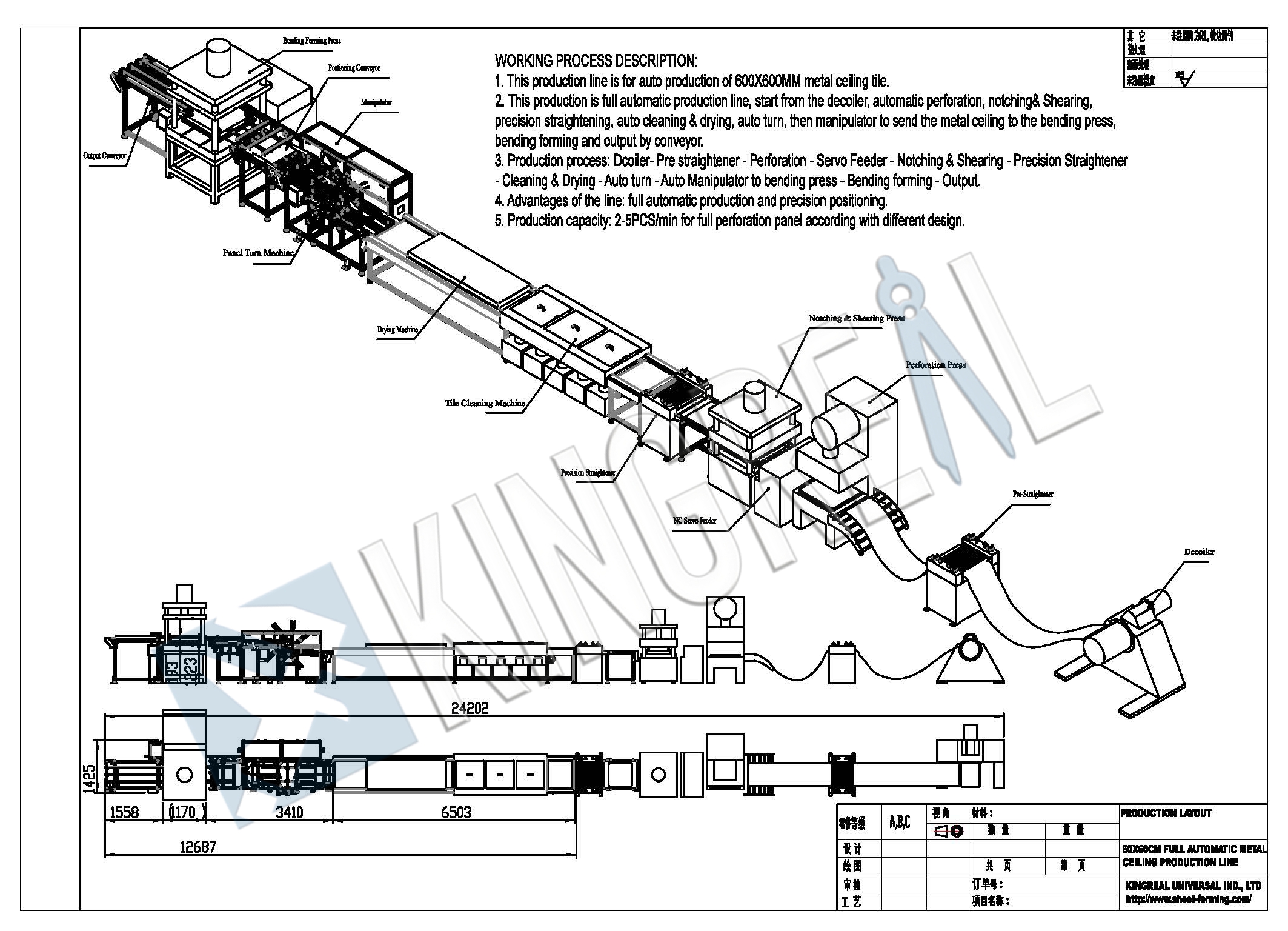

The metal ceiling making machine consists of multiple precision components, including decoilers, precision levelers, perforation presses, notching and shearing presses, servo feeding machines and auto bending forming presses. These devices work together to ensure the efficiency of the production process and the high quality of the products.

1.1Main components of metal ceiling making machine

Decoiler for metal ceiling tile production line: Used to unwind metal coils and prepare them for the production process. The decoiler can automatically adjust to ensure the smooth supply of coils. |  |

Precision leveler for metal ceiling tile production line: The precision leveler is responsible for correcting the corrugation and bending of the coils to make the input metal sheets flat. Flat sheets are the basis of high-quality metal ceiling boards. |  |

Punch press for metal ceiling tile production line: Punch press is used to punch holes in metal sheets for subsequent processing steps. Punch presses can be designed with holes of different diameters and shapes according to requirements. |  |

Notching and shearing press for metal ceiling tile production line: This equipment is used to cut metal sheets into the required size and shape to ensure that each metal ceiling panel meets the design requirements. |  |

Auto bending forming press for metal ceiling making machine: The bending forming press is the core equipment of the metal ceiling making machine. It presses the metal sheets into shape through high pressure to form the final metal ceiling panel. |  |

Through the efficient collaboration of these equipment, the metal ceiling tile production line can quickly and accurately produce various types of metal ceiling tiles.

2. Workflow of Metal Ceiling Making Machine

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press -- 2nd Precision Straightener -- Flipping machine -- Automatic tiles feeding machine -- Auto Bending Forming Machine

3. Reasons for Large Demand for Metal Ceiling Making Machines

As people's living standards improve, aesthetic concepts are also changing. As an important part of home decoration, the beauty and practicality of the metal ceiling tile have received more and more attention. This has led to an increasing demand for metal ceiling tile production lines.

3.1

Improved aesthetic needs

Modern consumers have higher and higher aesthetic requirements for indoor environments. The design of the metal ceiling panel should not only meet basic functional requirements, but also give people a sense of beauty visually. High-quality metal ceiling making machines can produce metal ceiling tiles of various styles and types to meet the personalized needs of different customers.

3.2

Development of the construction industry

With the acceleration of urbanization, the construction industry is also developing rapidly. The increase in new buildings has led to an increasing demand for metal ceiling boards, driving the market demand for metal ceiling tile production lines. In addition, the renovation and renovation of old houses also require a large number of metal ceiling tiles, further increasing market demand.

3.3

Functional requirements

Modern metal ceiling tiles not only have decorative functions, but also have multiple functions such as sound insulation, heat preservation, and fire resistance. Consumers' demand for the versatility of metal ceiling panels has led to the continuous updating and advancement of the technology of metal ceiling making machines to meet the new requirements of the market.

4. Different Types can be Produced by Metal Ceiling Tile Production Lines

The flexibility and diversity of metal ceiling making machines enable it to produce a variety of types of metal ceiling tiles to meet different market needs.

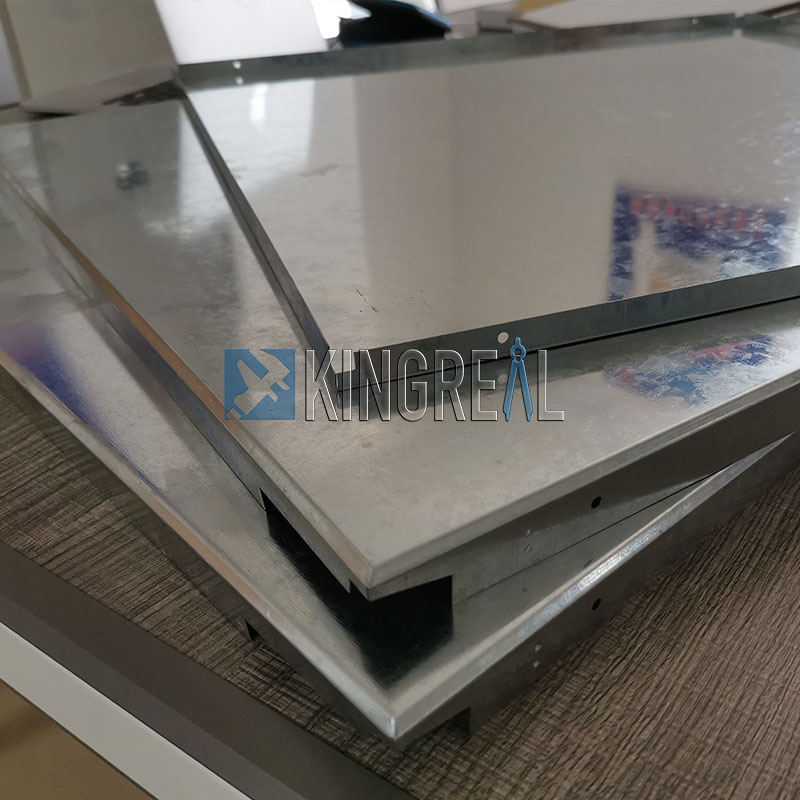

4.1 Plain metal ceiling tiles Plain metal ceiling tile is the most basic type of metal ceiling board and is a non-porous surface. It is usually used in commercial and industrial buildings. The production of this type of metal ceiling tile is relatively simple and suitable for large-scale production. |  |

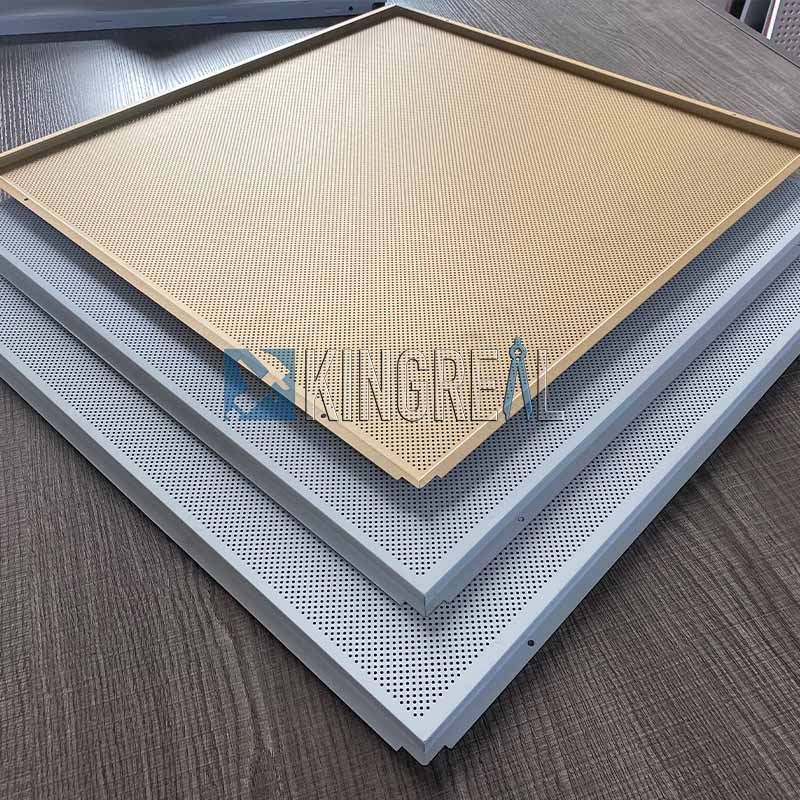

4.2 Perforated metal ceiling tiles Perforated metal ceiling tiles can be used with metal ceiling tile perforation lines to punch holes in the metal ceiling panel, which has good air permeability and aesthetics. Perforated metal ceiling tiles are widely used in office buildings, shopping malls and other places to increase the sense of transparency in the space. |  |

4.3 Other types of metal ceiling tiles The metal ceiling tile production line is also able to produce many different types of metal ceiling panels, such as Clip In metal ceiling tile, Lay In metal ceiling tile, Clip On metal ceiling panel, and Tegular metal ceiling tile. These types of metal ceiling boards are flexible in installation and removal and suitable for various building needs. |  |

The metal ceiling making machine is an indispensable part of modern building material production. It not only improves the production efficiency of the metal ceiling tile, but also meets the market demand for diversified and high-quality products. With the development of the construction industry and the continuous improvement of consumer aesthetics, the market prospects of the metal ceiling tile production line will be broader. Choosing an efficient and flexible metal ceiling making machine will bring greater competitive advantages and business opportunities to your business. If you want to know more about the metal ceiling tile production line, welcome to consult KINGREAL! Whether in terms of functionality, design or cost control, KINGREAL metal ceiling making machine can bring you surprises!