- Home

- >

News

Light gauge steel frame machines are widely used in the construction industry because they can produce profiles that are lightweight, high-strength, and easy to install. However, to ensure the long-term efficient operation of the light steel frame machine, regular maintenance is essential. This article from KINGREAL will provide you with a detailed explanation of how to effectively maintain your light gauge steel frame machine to improve its service life and production efficiency.

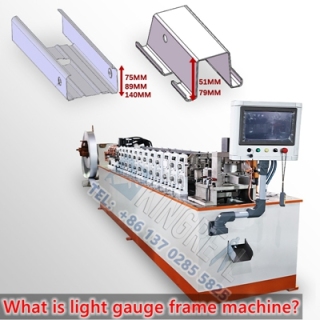

In the modern construction industry, the light steel frame machine has revolutionized traditional construction methods. Using galvanized steel as raw material, light gauge steel frame machine produces metal frames such as wall panels, floor trusses, and roof trusses through a cold-bending process, widely used in the construction of light steel structure houses.

LGS machine, or Light Gauge Frame Machine, is an advanced equipment for manufacturing light steel structures. By placing metal coils into the light gauge steel frame making machine, after a series of process steps, including uncoiling, leveling, punching, forming, coding, cutting, etc., different types and sizes of finished products, such as C-type, U-type and top hat, are finally produced. These finished products are widely used in building structures such as houses, walls and floors.