Drywall Stud and Track Machine Solution

2025-08-26 12:00Drywall stud and track machine is also known as drywall profile machine, gypsum channel machine or gypsum board metal profile machine. It is a highly efficient equipment specially used for producing various specifications of stud and track. This drywall profile machine is designed to meet the needs of interior wall frames and non-load-bearing wall frames, and can complete the production of products of different specifications in a short time.

This article will introduce the working process, finished product parameters, machine components and customized configuration of the drywall stud and track machine in detail to help customers better understand the advantages and applications of this drywall profile machine.

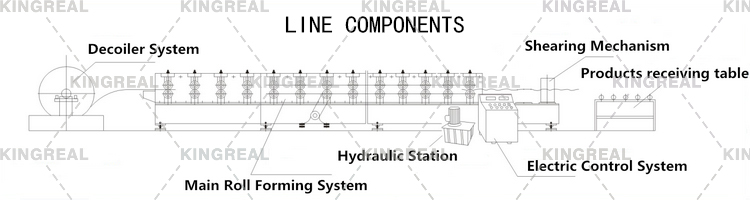

1/ Workflow of Drywall Stud and Track Machine

Decoiler--Main Roll Forming Machine--Hydraulic Fly Punching and Shearing System--Product Table--Auto Packaging Machine (optional)

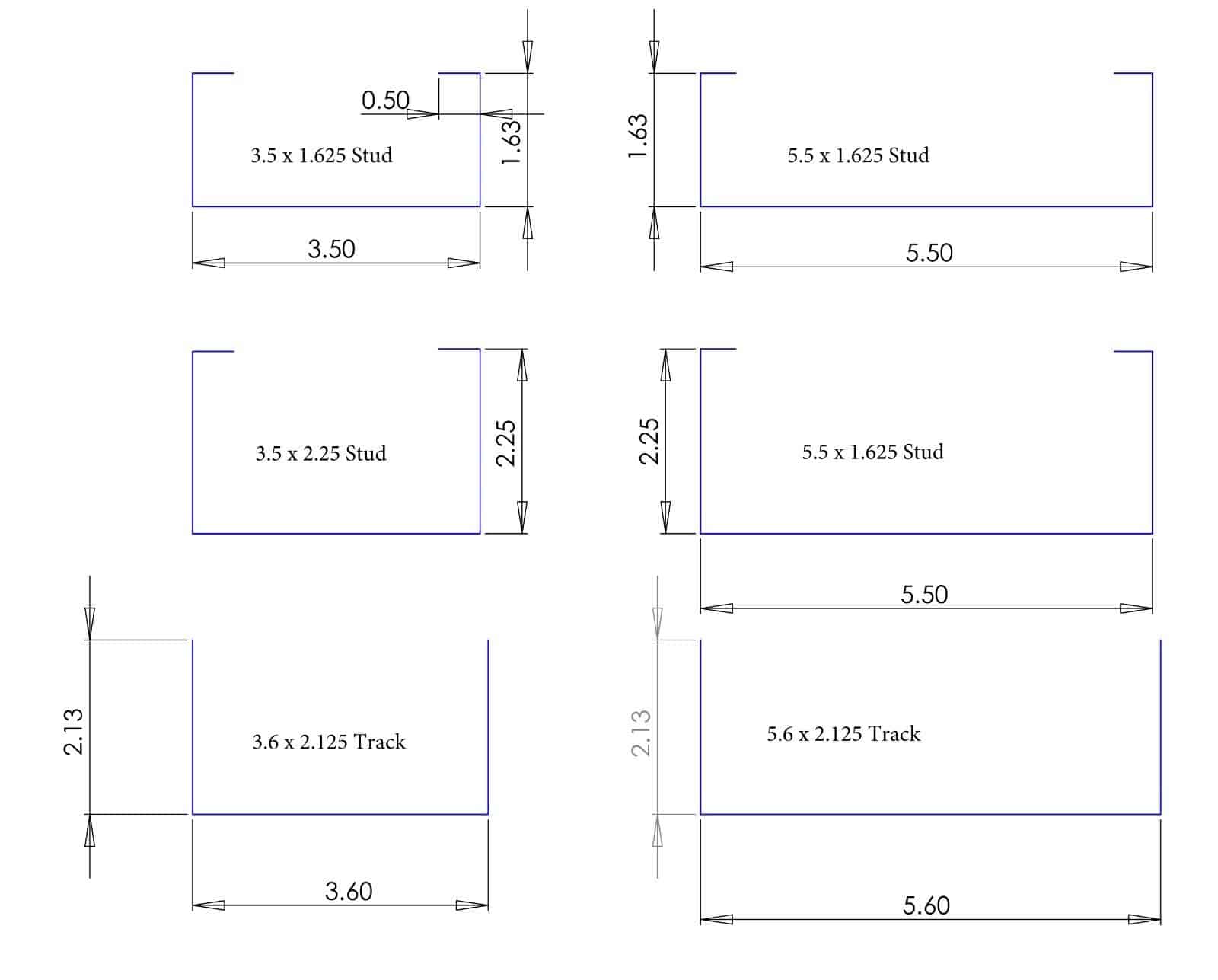

2/ Parameters of Stud and Track Product

The drywall profiles produced by drywall stud and track machine have various specifications and models, suitable for different building needs. The following are some of the main finished product parameters:

C Stud:

Coil Material: Galvanized steel, 50ksi

Width:41/51/63.5/92/152(1-5/8"/2.0"/2.5”/3.625"/6.0”)

Flange:12.7/32mm(0.5"/1.25”)

Lip: 1/4"-9/32"(5mm-6.5mm)

Thickness:(25gauge-20gauge)0.45mm-1.0mm

Yield Strength: Maximum 80ksi (550Mpa)

U Track:

Coil Material: Galvanized steel, 50ksi

Width:43/53/65.5/94/154.5(1-5/8"/2.0"/2.5”/3.625"/6.0”)

Flange:12.7/38mm(0.5"/1.5”)

Thickness:(25gauge-20gauge)0.45mm-1.0mm

Yield Strength: Maximum 80ksi (550Mpa)

3/ Introduction to Drywall Profile Machine Components

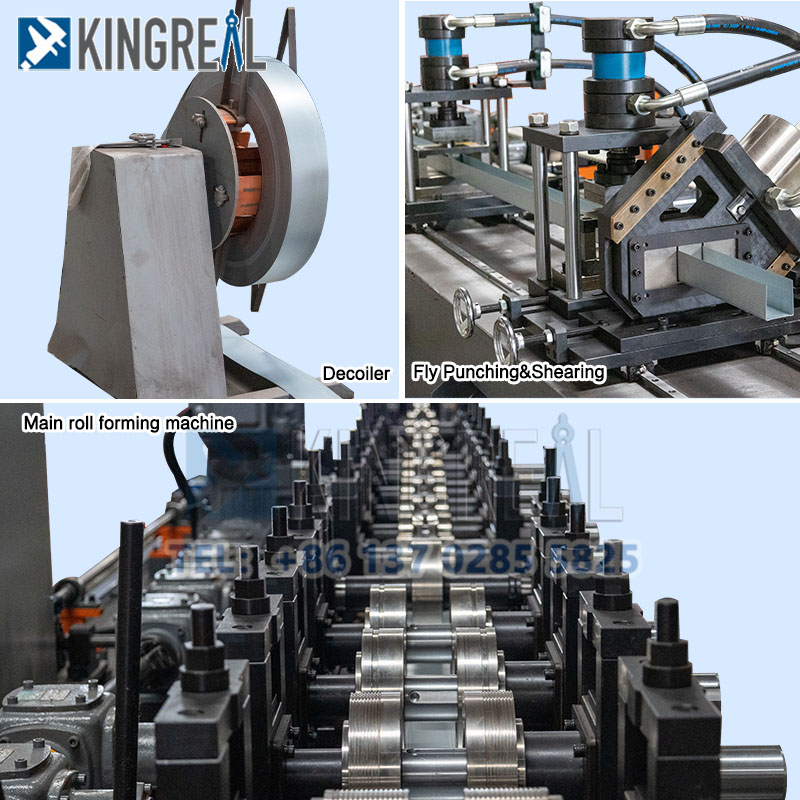

(1) Decoiler for drywall stud and track machine

Load capacity: 5 tons

Purpose: Support steel coils and uncoil them in a turntable manner, hydraulically tighten and relax, and ensure automatic feeding.

Steel coil inner diameter: 480-560 mm

Maximum material outer diameter: <Ф1200MM

Steel coil width: 300 mm

(2) Roll forming machine for drywall profile machine

The core part of the drywall stud and track machine is the main roll forming machine. KINGREAL has equipped the drywall profile machine with a split roller, which allows one machine to produce drywall stud and track of different sizes. Users can make automatic adjustments through PLC.

Roller material: 45# steel, ensuring durability and stability.

Tempering treatment: Improves the hardness and wear resistance of the shaft.

Roller material: Cr12, quenched to enhance cutting ability.

Working power: 7.5 kW + 11 kW

Transmission mode: gearbox, ensuring the stability of power transmission.

(3) PLC control system for drywall profile machine

The PLC control system is the intelligent core of the drywall stud and track machine, allowing users to set the required product size, speed and other parameters.

Function of PLC control system:

Computer controls the length and quantity, and the drywall profile machine automatically cuts according to the settings. Length errors are easily corrected to ensure product quality.

(4) Fly punching and shearing system for drywall profile machine

This system is an important part of the drywall stud and track machine and is responsible for efficient cutting.

Working mode: servo flying knife and hydraulic cutting system.

Cutting length tolerance: ±1 mm, ensuring accuracy.

Drive mode: column cylinder, providing powerful cutting power.

(5) Automatic packaging machine for drywall profile machine

The drywall stud and track machine can also be equipped with an automatic packaging machine to further improve production efficiency.

Maximum speed: 70 m/min, quickly completing the packaging work.

Number of workbenches: 1, easy to manage and operate.

4/ Customized Configuration of Drywall Profile machine

KINGREAL is well aware that each customer has different requirements for equipment during the production process. Therefore, KINGREAL provides a series of customized configuration services to meet the specific needs and expectations of different customers. This flexible customization solution not only enhances the applicability of the drywall stud and track machine, but also helps customers stand out in the fierce market competition.

Inkjet device for drywall profile machine:

In order to meet the market's high attention to brand recognition and product traceability, KINGREAL drywall stud and track machine can be equipped with a high-precision inkjet device. This device allows customers to modify and update brand names, model information, and other necessary markings in real time via the PLC control panel during the production process. This flexibility enables customers to quickly adjust printed content based on market demand or product line variations. The inkjet device not only enhances product competitiveness but also strengthens brand recognition, making it easier for consumers to identify and choose trusted brands.

Rollers engraved with customer's required logo:

KINGREAL also offers rollers engraved with customer's desired logo as another custom option. This roller prints the customer's brand directly onto the profile surface at the start of production, creating a permanent mark. While this method cannot be used to change brand information during the production process, it provides a stable and consistent brand image, helping to establish long-term recognition in the market.

Inkjet device vs. logo-engraved roller

While both inkjet devices and logo-engraved rollers ultimately display the customer's brand information on the product surface, they each have different application scenarios and advantages. The flexibility of inkjet devices makes them suitable for situations where frequent product marking changes are required, while logo-engraved rollers are suitable for brands that desire a consistent and stable image. Customers can choose the customized configuration that best suits their production needs and market strategies.

The KINGREAL drywall stud and track machine meets the diverse requirements for studs and tracks in modern construction. Through a streamlined workflow, precise product parameters, and customized configurations, it offers customers significant production efficiency and cost savings. As the construction industry continues to evolve, this drywall stud and track machine will continue to play a vital role, driving upgrades and innovations.

KINGREAL hopes this article will provide valuable reference for practitioners in related industries, if you are interested in KINGREAL drywall stud and track machine, welcome to consult KINGREAL!