Roll Forming Machine For Drywall

2025-11-20 17:40KINGREAL boasts a range of advanced roll forming machines specifically designed for producing galvanized steel profiles for gypsum board applications. This roll forming machine not only enhances production efficiency but also ensures high-quality finished products. Depending on the application, these profiles are typically categorized as ceiling profiles, wall profiles, and corner profiles.

1. KINGREAL Roll Forming Machines for Drywall

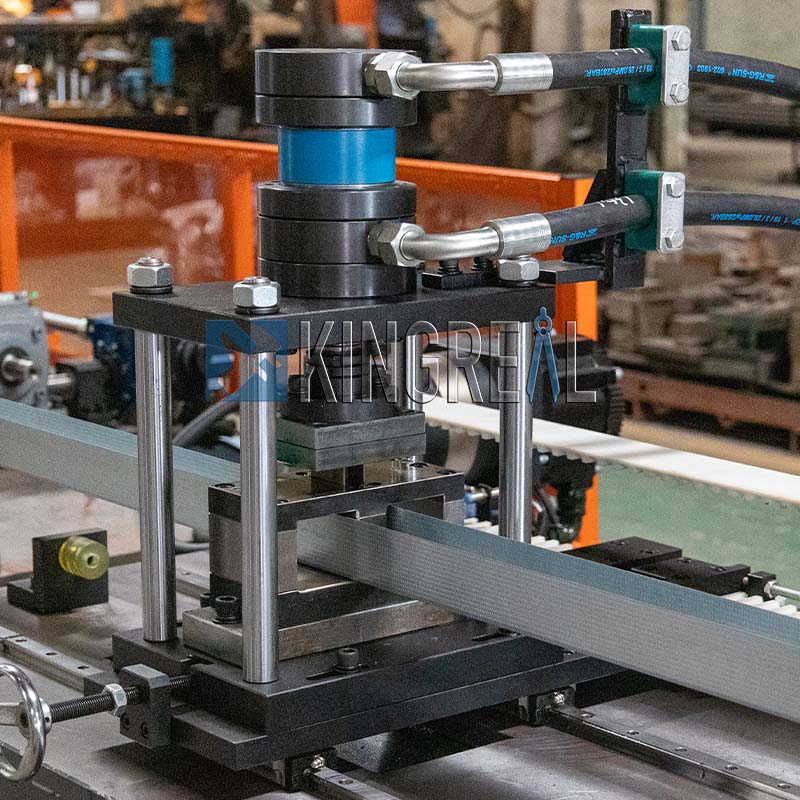

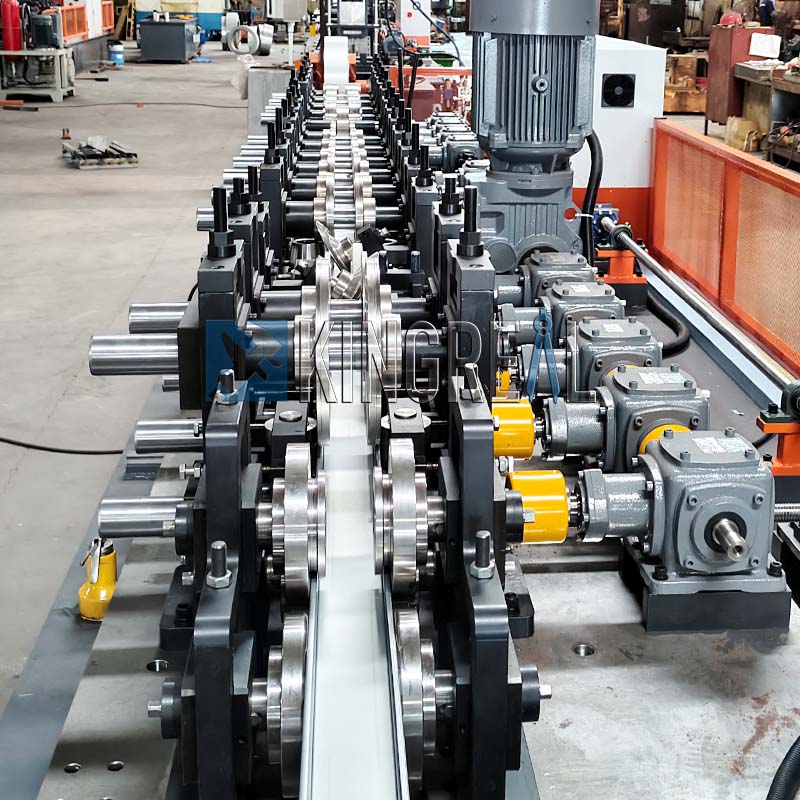

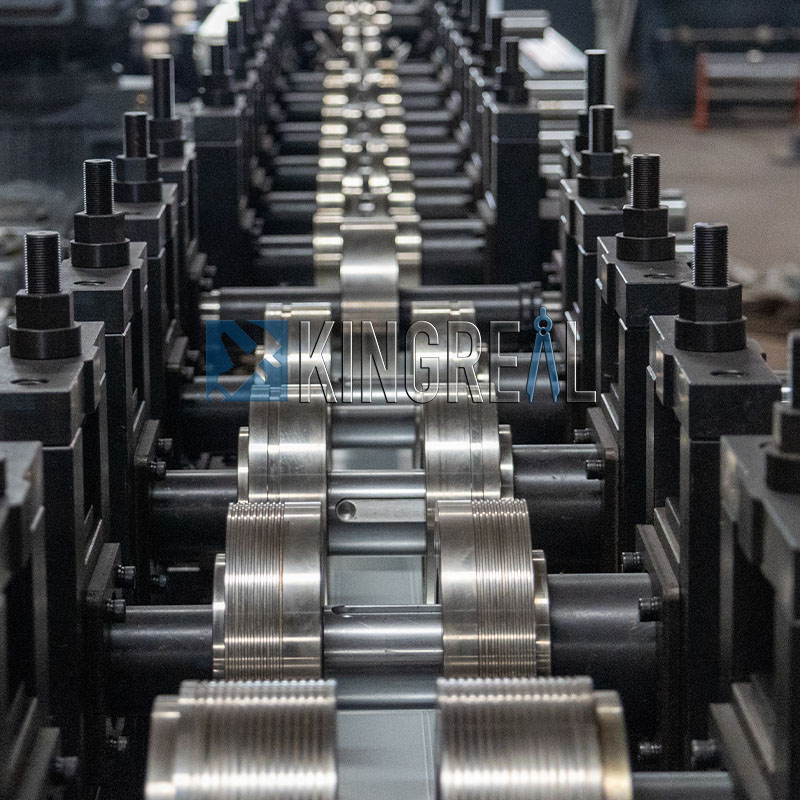

KINGREAL roll forming machines utilize advanced technology and fully comply with CE standards. This is reflected not only in the design and manufacturing of the roll forming machine but also in the adherence to various safety regulations during production. The roll forming machine comprises precision components such as decoilers, roll forming units, and hydraulic cutting systems, while an advanced PLC control systems the entire production process. This intelligent design allows manufacturers to easily configure remotely and monitor potential anomalies in real time, significantly enhancing operational safety and convenience.

2. Advanced Customized Roll Forming Machines for Drywall

KINGREAL roll forming machines are highly adaptable, flexibly meeting diverse production needs. For example, the roll forming machine allows for quick changes of rollers or complete sets of molds to facilitate the production of different gypsum board profiles. Furthermore, the roll forming machine can be integrated with additional hydraulic units to enable customized operations such as grooving or reinforcement (stiffening). This flexibility not only improves production efficiency but also meets customers' diverse product needs. In the actual production process, the roll material is first loaded onto the decoiler, then passes through a centering system and forming roller assembly to ensure millimeter-level precision. The cutting unit then cuts the material in real-time according to the customer's required length, achieving efficient production. Through a rational workflow and intelligent control, KINGREAL roll forming machine operates efficiently, minimizing downtime.

The roll forming machine's production process begins with data input. Users can input processing details (such as the required profile length, type, and quantity) into the PLC to initiate automatic production. Alternatively, the machine supports manual input or remote transmission of cutting lists for autonomous production, significantly improving efficiency. During cutting, a dedicated cutting device ensures precise cuts, and the standard forward gear provides added accuracy. If needed, the roll forming machine can also be equipped with a fly cutting function to further shorten cycle time and improve production efficiency.

3. Safety Design and Compliance for Roll Forming Machine

Safety is always a top priority in the design of KINGREAL roll forming machine. The roll forming machine is equipped with photoelectric sensors, active and passive safety systems, and strictly adheres to CE standards to ensure operator safety. Furthermore, real-time production data storage provides strong support for the roll forming machine's safety and efficiency. In case of an emergency, the roll forming machine will automatically stop and issue an alarm. These designs undoubtedly enhance the roll forming machine's user-friendliness, allowing operators to work with greater peace of mind.

4. Advantages and Customization Options for Roll Forming Machine

KINGREAL roll forming machines utilize the latest technology, ensuring they meet the highest industry standards in safety, operability, and production efficiency. The hydraulic unit can be customized to specific production needs, providing a wider range of processing capabilities. Simultaneously, the quick-change tool function minimizes downtime and improves overall production efficiency. These advantages not only meet the current market demand for high-quality roll forming machines but also provide customers with more customization options.

5. Multiple Advantages of Gypsum Board

Gypsum board is increasingly favored in modern construction due to its lightweight, economical, and easy-to-install properties. Compared to traditional building materials, gypsum board allows for faster installation, especially in large-scale construction projects, significantly improving construction efficiency. Furthermore, when used in conjunction with insulation materials, gypsum board enhances the building's thermal and sound insulation performance, creating a more comfortable indoor environment. In addition, modern design concepts make gypsum board an ideal building material for creating niches, irregularly shaped ceilings, or curved walls, among other distinctive spaces.

6.Profiles Achievable with KINGREAL Roll Forming Machine for Drywall

-Omega profile: Commonly used in the construction industry for wall, ceiling, and roof insulation. Omega profiles are typically made of galvanized steel and used for transporting and securing structural components.

-Stud & track: Two metal profiles used for walls, designed to enhance the strength and support of the wall structure.

-CD (C for ceilings): As a load-bearing structure forming the ceiling, used to install ceiling panels or ceiling strips. Due to its durability and ease of installation, ceiling c profiles is widely used in ceiling systems.

-UD (U-perimeter profiles): Profiles for installing drywall. They can be used alone or in conjunction with ceiling c profiles for standard drywall ceilings and concealed drywall lighting applications.

-Drywall corner profiles: Special profiles for interior drywall corner connections. These profiles reinforce drywall corners, provide a smooth surface, and contribute to a durable structure.

If you are looking for reliable and efficient drywall production solutions, please contact KINGREAL. KINGREAL offers a variety of roll forming machines for drywall, including omega channel machine, stud and track machine, plasterboard corner bead machine, c channel making machine, and u channel making machine. KINGREAL roll forming machines can meet diverse needs and provide various customized services to ensure your production plans run smoothly. If you have purchasing needs or would like to learn more about the different models and types of roll forming machines offered by KINGREAL, please feel free to contact KINGREAL. We look forward to providing you with high-quality machines and services!