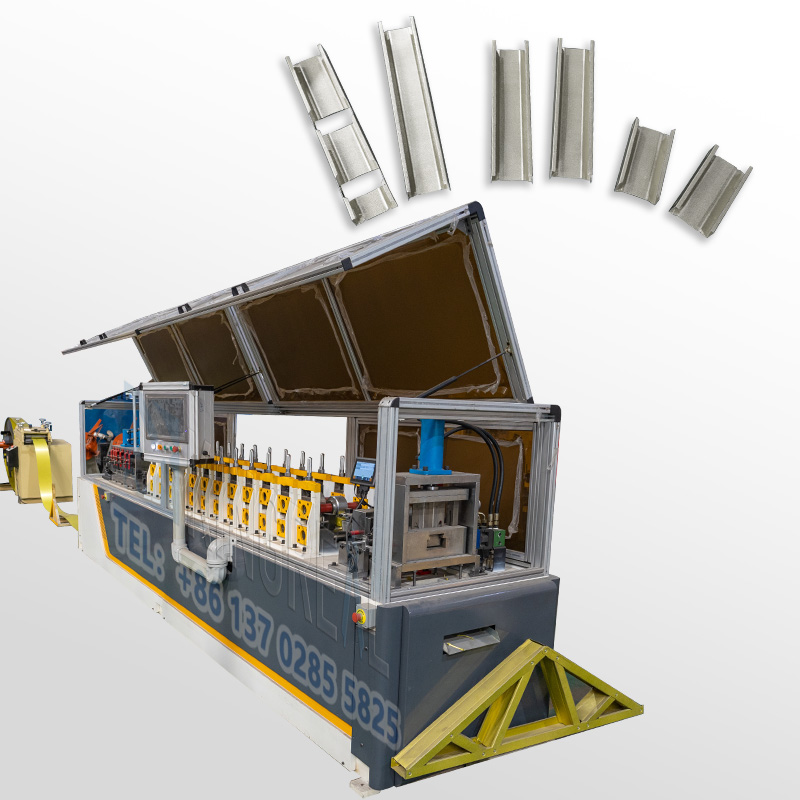

What is light gauge steel framing machine?

2025-07-30 12:00The light gauge steel framing machine for light steel villa profiles is an efficient equipment that utilizes advanced CAD-assisted design and CAM-assisted production and manufacturing technology for light steel houses.

It can not only design building structures, but also realize 2D and 3D modeling of interior design and landscape design.

The light steel villa structure machine can automatically generate material tables and estimation facilities to effectively calculate design costs by meeting the personalized needs of customers through precise engineering construction drawings.

The produced profiles can complete the skeleton work of light steel villas through simple and orderly installation, and are widely used in the construction industry.

1/ Introduction to Light Gauge Steel Framing Machine

The process flow of the light steel villa structure machine includes fully automatic two-in-one hydraulic automatic unwinding, leveling machine, automatic high-speed punching, high-speed forming, automatic coding and automatic cutting. This series of processes is realized under the intelligent production of mechanical automatic assembly lines. The light gauge steel framing machine processes all screw installation holes, pipeline water and electricity holes, and anchor holes. Each keel has a unique code, which can be simply screwed according to the drawings and quickly assembled into the keel frame of the light steel house. Due to the high degree of automation and simple operation of the light steel villa structure machine, the speed of on-site construction can be significantly improved. |  |

2/ Features of Light Gauge Steel Framing Machine

1. Reliable quality light steel villa machine

This light gauge steel framing machine weighs 5.5 tons and adopts a sturdy heavy-duty design. The fine craftsmanship ensures its stability. Whether in the domestic or export market, the light steel villa structure machine can be put into production quickly, reduce installation and commissioning time, and run stably.

2. Fully locked screw assembly method

The light steel villa machine uses CNC machining center for fine processing, and all uses full-lock screw assembly method, which reduces the possibility of deformation and is relatively simple to maintain.

3. Gearbox design for light steel villa structure machine

The independent arch-style gearbox design makes the light gauge steel framing machine run smoothly, which can ensure long-term high-speed operation without deformation and shaking, so that the size of the keel punching is more accurate and easy to install.

4. Intelligent control system for light steel villa structure machine

The light gauge steel framing machine is equipped with an optimized computer intelligent control system, which is easy to operate.

After simple training, the operator can easily get started in half an hour, greatly improving work efficiency.

The fully automatic light steel villa structure machine produced by KINGREAL adopts PLC computer centralized programming control system, and the variable frequency speed regulating motor controls the high-speed hydraulic automatic cutting device (front punching/back cutting) of the light gauge steel framing machine to ensure the fixed length cutting, the size of the formed product is accurate, and the operation is stable.

By directly inputting the length, the light steel villa structure machine can automatically measure and cut the plate, which greatly improves the processing efficiency.

5. Variable frequency hydraulic system

The light gauge steel framing machine adopts a variable frequency hydraulic control system with imported components, which can perform high-frequency punching for a long time, with high efficiency and stable operation.

3/ Efficient Processing System for Light Steel Villa Structure Machine

KINGREAL light gauge steel framing machine is equipped with an efficient online stamping system, which can punch and cut synchronously, complete the processing of products at one time, and significantly save manpower and material resources. The fully automatic light steel villa structure machine adopts a standard roller mold, which is treated with high temperature quenching to ensure the wear resistance and service life of the mold.

At the same time, the performance of the formed profile is stable and can meet the needs of various types of buildings.

4/ Fully Intelligent Light Gauge Steel Framing Machine

The operation of the light steel villa structure machine depends entirely on fully automatic computer control and automatic rolling processing. After forming, the light gauge steel framing machine will automatically perform stamping (such as LOGO or punching, which can be customized on demand).

When the produced profile reaches the specified length, the light steel villa structure machine will automatically cut off and use a hydraulic mold for shearing. The cutting blade is made of Cr12mov material, which ensures the high performance and long service life of the blade.

5/ Excellent Performance of Light Gauge Steel Framing Machine

The profiles produced by the light steel villa structure machine are very stable in performance. The partitions usually consist of light steel villa stricture and 2 to 4 layers of gypsum boards, and their fire resistance can reach 1.0 to 1.6 hours. This makes the light steel villa structure have excellent performance in the construction industry and can meet various building safety standards.

The standard roller wheel mold used by the light gauge steel framing machine has been finely processed to ensure the accuracy and smoothness of each workpiece, maintain the good appearance of the finished product, avoid paint slippage, and achieve low wear.

This light steel villa structure machine is a cold bending and pressing machine specially used for the production of light steel villa structures. This profiles produced correspond to the light steel structure villa frame.

6/ Application of Light Steel Villa Structure Machine

Common models of light gauge steel framing machine include 89, 140 and 300. These models can flexibly select light gauge steel framing of different specifications and sizes according to the requirements of building structure design. The profiles processed by light gauge steel framing machine are widely used in rural self-built steel structure villas, housing projects, relocation of the whole village steel frame house, urban farm construction, scenic area supporting housing, tourist public toilet construction, hot spring resort hotel, school kindergarten construction, etc.