What's the advantages of ceiling t grid machine?

2025-07-27 12:00As an important equipment in the production of modern building materials, the ceiling t grid machine is widely used in the manufacture of metal ceilings. It produces the main t (runner t) and the cross T by processing iron plates of different thicknesses and roll-coated iron plates, providing stable and solid ceilings for buildings. This article will discuss in detail the workflow, technical parameters and multiple advantages of the ceiling t bar machine in the industry. |  |

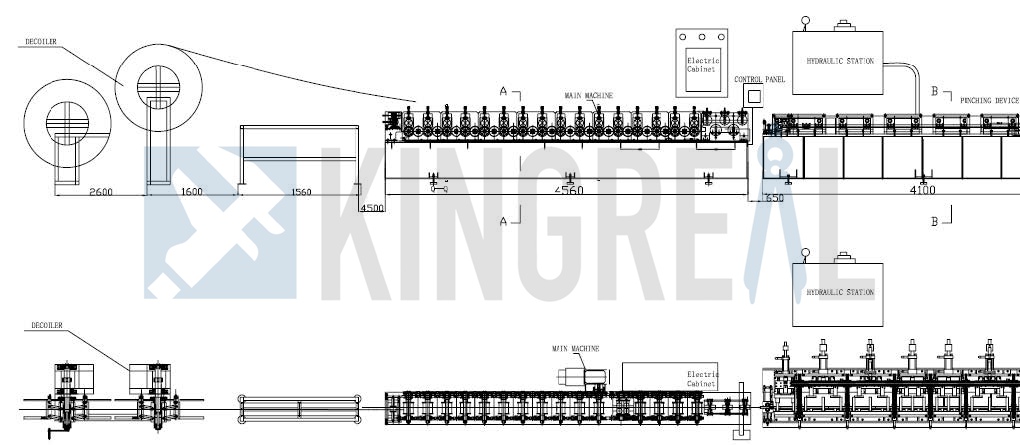

1/ Working Process of Ceiling T Grid Machine

Hydraulic Decoiler -- Main Roll Forming Machine -- Punching and shearing station--Product table

2/ Technical Parameters of Ceiling T Bar Machine

| Name | Specification |

| Decoiler | 2set, manual decoiler, loading 1.5Ton |

| Roller | 18 Rows Material:Cr1 shaft diameter:Φ40mm2 |

| Transmission | 5.5kw main motor with K reducer. Gear transmission |

| Side Plate | Thickness 25mm, grinding six-sided, high-precision boring from processing |

| Feeding Positioning | Manual positioning, flexible adjustment at both ends |

| PLC | PLC programming controller |

| Stamp Die | Material:10 Sets,SKD11 |

| Hydraulic motor power | 15KW,EDC24V solenoid valve |

| Output table | 1 set |

| Ball screw | 2, Precision guidance |

| Servo motor | 15KW Servo Motor |

| Total Power | Ceiling t bar machine is 20.5KW |

| Speed | Around 30m/min |

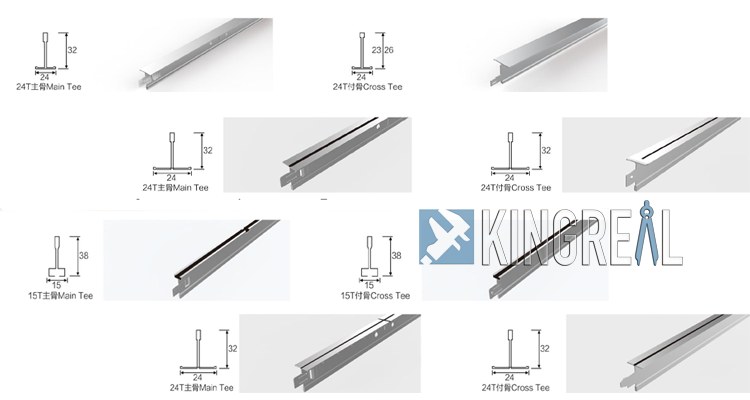

3/ Drawing About Ceiling T Bar

4/ Advantages of Ceiling T Grid Machine

1. PLC control panel for ceiling t bar machine

The ceiling t grid machine is equipped with a PLC control panel that can monitor the production process in real time.

If the ceiling t bar machine fails, the PLC control panel can automatically locate the fault location, making it convenient for workers to perform maintenance.

This intelligent management method improves production efficiency, reduces downtime caused by failures, and thus optimizes the overall production process.

2. High-speed ceiling t grid machine

The maximum speed of the ceiling t bar machine can reach 30m/min, which is at the leading level in the industry. High-speed operation not only improves production efficiency, but also meets the needs of large-scale production, giving companies an advantage in market competition.

3. High-configuration ceiling t grid machine

KINGREAL provides a variety of ceiling t bar machine manufacturing solutions, including high-configuration ceiling t grid machines.

KINGREAL engineers have equipped these ceiling t bar machines with safety protection shields and hydraulic oil cooling systems to ensure safe operation and extend the service life of the ceiling t grid machine.

At the same time, the high configuration of the ceiling t bar machine also means higher production efficiency and better finished product quality.

4. Complete solution

KINGREAL not only provides ceiling t grid machines for the production of main t and cross t, but also wall angle profile machines and lay in ceiling tile production lines. The combination of these equipment can form a complete metal ceiling system, which greatly simplifies the customer's procurement process and saves time and cost.

5. Precision ceiling t grid machine

The ceiling t bar machine adopts a precise design in the forming and punching links. Especially in the punching process, KINGREAL adopts an overall punching system design to ensure the accuracy of the punching position.

The full-length punching technology allows each product to be completed in one-time punching, with fast speed and accurate position.

In addition, the ceiling t grid machine uses pneumatic push rods and cables to be arranged neatly, further improving production efficiency.

6. Different types of ceiling t bar machines

KINGREAL can provide four different types of ceiling t grid machines: Black line ceiling t bar machine, Flat ceiling t grid machine, Silhouette ceiling t bar machine, and FUT ceiling t bar machine.

Customers can freely choose according to their production needs and usage. And for each ceiling t bar machine, KINGREAL engineers will adjust the parameters and performance according to the customer's drawings and combined with the actual production situation, and will add accessories such as protective shields to the ceiling t grid machine if necessary.

The ceiling t bar machine has become an indispensable equipment in the modern construction industry with its high efficiency, precision and stability.

Through an in-depth analysis of the ceiling t grid machine's workflow, technical parameters, and multiple advantages, we can see that this equipment plays a significant role in improving production efficiency, ensuring product quality, and reducing costs.

If you are interested in the ceiling t bar machine and need to obtain more ceiling t grid machine parameters or operation videos, please contact KINGREAL!