What Types of Drywall Profiles can Stud And Track Machine Produce?

2026-01-05 18:13In the modern construction industry, using drywall as an interior wall material has become a trend. The stud and track machine, which produces high-precision drywall profiles, is a crucial tool for realizing this trend. KINGREAL designs various customized stud and track roll forming machines based on customers' actual project needs. These stud and track machines utilize a fly shearing system to precisely cut materials of various widths and thicknesses, producing profiles with extremely tight tolerances. These drywall profiles not only have excellent structural performance but also meet the needs of different construction projects.

▍Stud and Track Machine for Various Sizes of Drywall Profiles

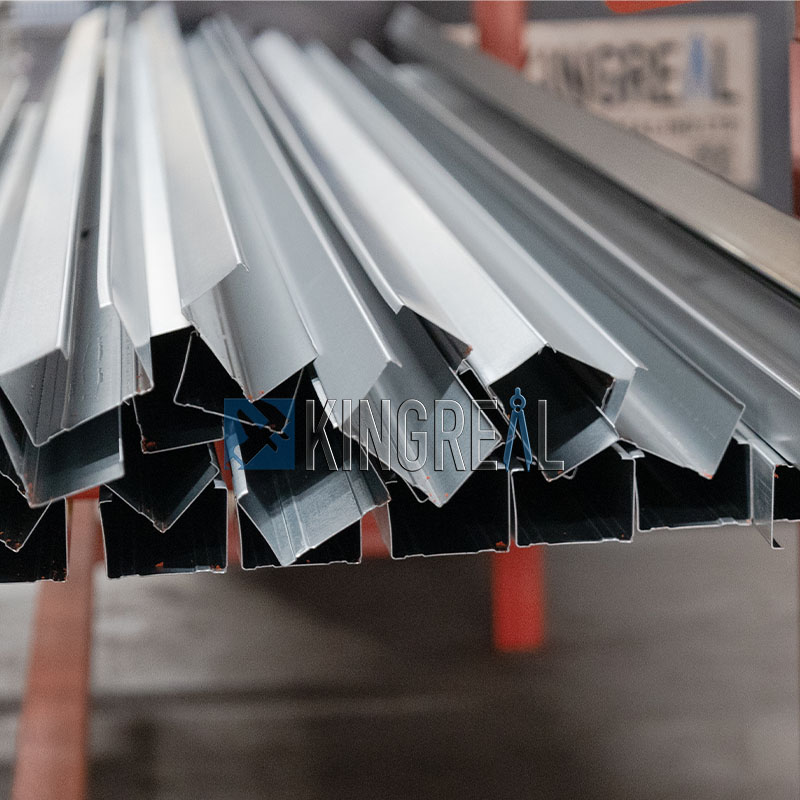

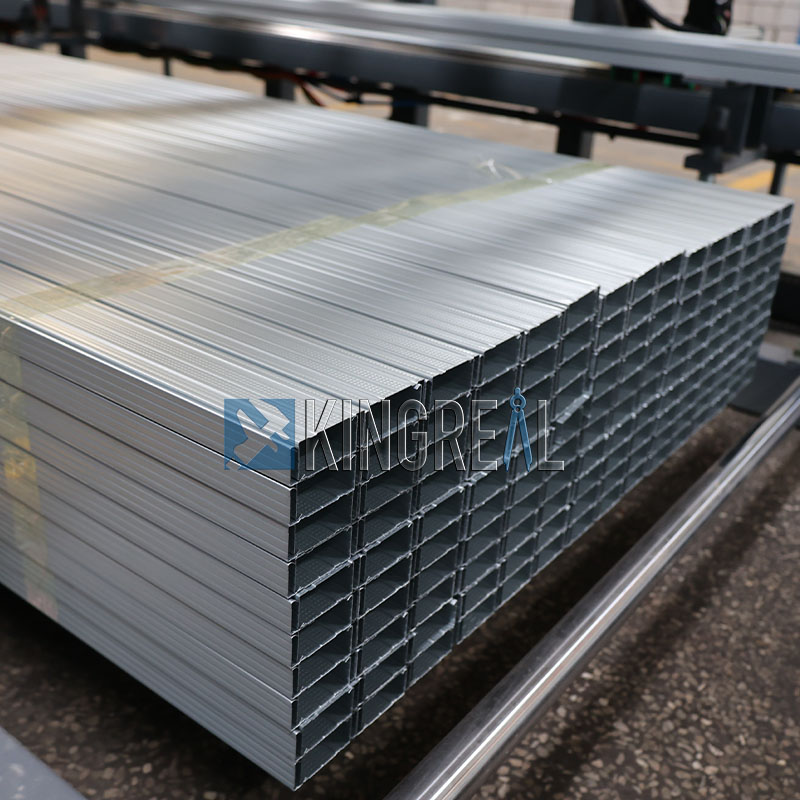

A single stud and track roll forming machine can produce multiple specifications of drywall profiles. All components are customized and equipped according to the design, providing multiple options to meet customer needs. The stud and track machine can produce both light gauge stud & track and structural stud & track.

●Light Gauge Stud & Track

The stud and track roll forming machine has significant advantages in producing light gauge studs and tracks. The following are its specific production characteristics:

Material Thickness: Applicable material thickness ranges from 20 to 26 gauge, meeting the needs of lightweight structures.

Decoiler Options: Single-arm or double-arm decoilers are available, and a feeding trolley is provided to enhance the convenience of material handling.

Web Size: The web size can be selected from 1-5/8" to 6" depending on project requirements, to adapt to different design requirements.

Flange/Leg Height: The adjustable stud flange height is between 1-1/4 and 2-1/2", and the track flange height is also 1-1/4 to 2-1/2".

Lip Size: The lip size ranges from 1/4" to 1/2", and smaller or larger sizes can be customized as needed.

High-Precision Process: The internally designed high-precision roller dies ensure that the produced drywall profiles have excellent dimensional stability and strength.

Adjustment Function: The machine provides automatic or manual width adjustment, and some models also support automatic thickness adjustment to meet the production needs of different materials.

Post-Punching: Post-punching dimensions can be customized according to customer specifications. The stud and track roll forming machine is also equipped with a cutting station with different sizes and profile blades to meet diverse production needs.

●Structural Stud & Track

The stud and track machine can also produce structural studs and tracks, suitable for larger and higher-strength building requirements, as follows:

Material Thickness: Can handle material thicknesses from 12 to 20 gauge, suitable for higher load-bearing capacity designs.

Web Size: Meets web size requirements from 3-5/8" to 14", suitable for large structures.

Flange/Leg Height: The flange height of the stud ranges from 1-5/8" to 3", enhancing material strength.

Lip Size: The lip size is between 1/4" and 1", and can also be customized according to customer needs.

High-Precision Molds: Like light-gauge profiles, structural profiles also use internally designed high-precision roll molds to ensure product quality and stability.

Punching and Cutting Options: Pre-punching dimensions can be customized according to customer specifications, and a post-cutting shear can be selected for thinner materials.

▍Stud and Track Machine Equipped with Customized Components

Based on actual customer production needs, the stud and track roll forming machine is designed with customized components to enhance stud and track machine performance and production efficiency.

1)Double head decoiler for stud and track machine

The double head decoiler allows for simultaneous unwinding and feeding from one coil while loading another. This design ensures the continuity of the stud and track roll forming machine, reduces the time required for material changeover and adjustment, and improves overall production efficiency. This flexible solution is ideal for high-volume production.

2)Automatic packaging unit for stud and track machine

The automatic packaging unit is closely integrated with the stud and track roll forming machine. After the drywall profiles are cut and delivered to the output table, it automatically performs a series of operations including fastening, lifting and stacking, tape wrapping, material pulling, palletizing and pallet lifting. This not only solves the problem of labor costs but also saves a significant amount of time, ensuring work quality and production speed.

3)Protective shield for stud and track machine

To ensure the safety of the operators, the stud and track roll forming machine is also equipped with a protective shield, specifically protecting the forming area. This design prevents workers from being injured by accidentally touching the rotating rollers. At the same time, the protective shield can be opened at any time after the stud and track roll forming machine stops running, facilitating daily cleaning and maintenance. This safety design effectively guarantees production safety and protects the factory environment.

4)Inkjet device for stud and track machine

In addition to basic production functions, the stud and track roll forming machine can also be equipped with an inkjet device to meet customers' production needs for unique finished products. In the forming section, the inkjet device can print the logo or model number required by the customer onto the profiles, enhancing the brand's market competitiveness. This innovative design ensures the uniqueness of the product in the market and strengthens the customer's brand image.

KINGREAL hopes that through this article, you can gain a deeper understanding of the stud and track machine and discover this versatile and flexible machine for producing drywall profiles. Whether you have production needs for light gauge stud and track or structural stud and track, KINGREAL stud and track roll forming machines can meet your requirements.

◆Contact KINGREAL Today

For more information, technical specifications, or a custom quote, reach out to the KINGREAL team. Discover how stud and track roll forming machine can transform your drywall profile production business and give you the competitive edge you need in today's global market.