- Home

- >

News

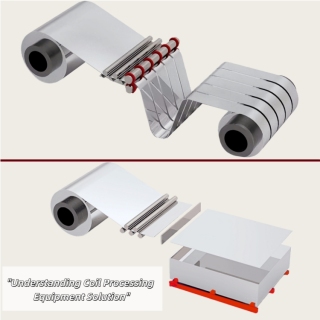

Metal cut to length lines are precision coil processing equipment commonly used in the automotive industry, primarily for uncoiling, straightening, cutting, and stacking large metal coils used in automobile manufacturing. In the automotive industry, metal cut to length machines provide manufacturers with high-quality metal sheets that offer high surface quality, burr-free cuts, optimal flattening effects, and neat, standardized finished product stacks, ensuring no collisions or scratches. Because the precision sheets produced by metal cut to length lines undergo secondary processing, they can be used to manufacture important automotive components such as chassis, axles, suspension parts, doors and hoods, fuel tanks, interior parts, and body panels, thus enjoying widespread market demand.

Coil processing line plays a vital role in modern manufacturing. Whether in the automotive, home appliance, or building materials industries, coil processing equipment solutions provide strong support for improving production efficiency and product quality. Leveraging its extensive experience and technology, KINGREAL offers customers a wide range of coil processing equipment solutions, primarily for processing steel, stainless steel, copper, silicon steel, aluminum, PPGI, and other materials.

The successful installation of a KINGREAL metal cut to length line at a customer's factory in Indonesia marks another success for KINGREAL in the international market. The metal cut to length machine is currently operating stably at the customer's facility, delivering significant production benefits. This success story not only demonstrates the superior performance of KINGREAL metal cut to length line, but also exemplifies the comprehensive service KINGREAL provides to its Indonesian customers. This article will detail the services KINGREAL provides, including specific applications in Indonesia.

The metal cut to length machine is also known as steel coil cut to length line, ctl line, coil cut to length line. It is simple and reliable to operate, and the stacking is neat. It has a high degree of automation, high precision in fixed length, and high flatness of the sheet. The metal cut to length machine is mainly composed of a frame, a knife holder, a drive motor, a transmission mechanism, a cutting device, etc. According to the required shearing length, the shearing data is input. After the switch is turned on, the drive motor drives the transmission mechanism to move the knife holder horizontally to cut the material into the required length. The steel coil cut to length line has the advantages of high precision, fast cutting speed, easy operation, simple maintenance, and durability. It is widely used in the processing and sheet metal cutting.