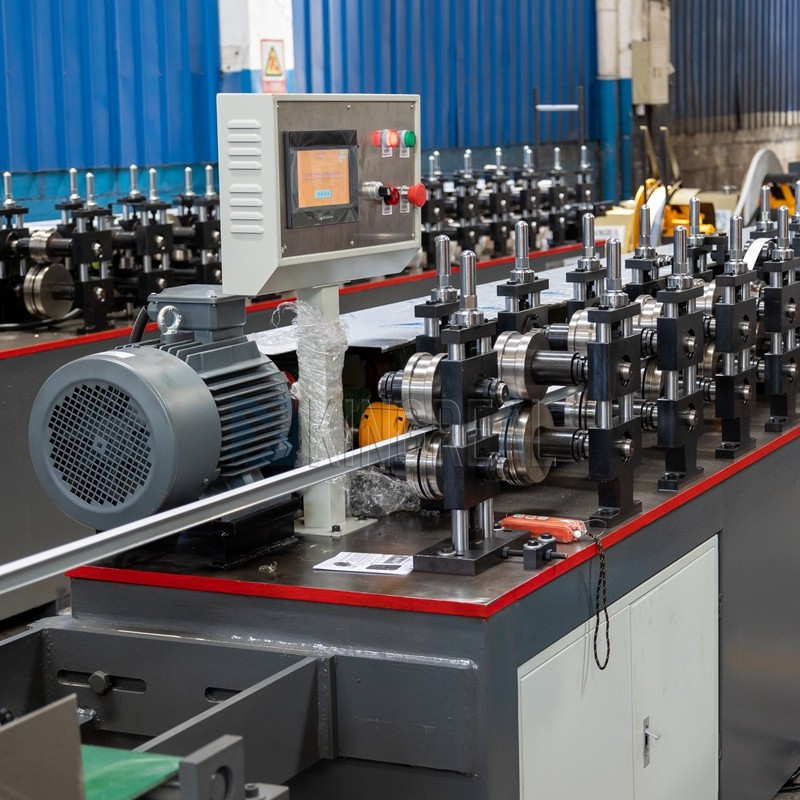

2025 NEW Design For Ceiling T Grid Machine

2025-09-12 12:00Ceiling T grid machines, as crucial equipment for supporting suspended ceiling panels, play an indispensable role. For customers in Italy and North America, KINGREAL intends to design and produce a new generation of ceiling t bar machines in 2025. Customized ceiling t bar machine manufacturing solutions from KINGREAL offers customers in nations including Brazil, Saudi Arabia, India, Indonesia, Russia, and Vietnam effective and exact production solutions.

KINGREAL is a specialized manufacturer of metalworking equipment with over two decades of industry experience. Worldwide customers have grown to rely on KINGREAL ceiling t grid machines for their great performance and consistent quality. Driven by innovation, the company is committed to creating new technologies to satisfy rising market demands.

Ceiling T Grid Machine Design Overview

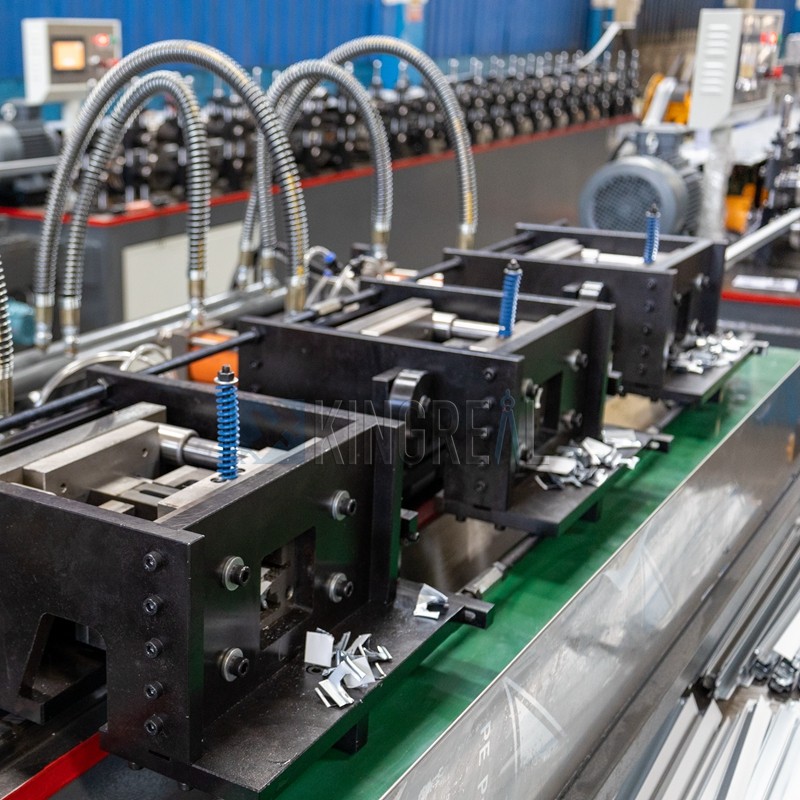

The ceiling t bar machine consists of several key components, including a hydraulic decoiler, a main roll forming machine, a punching and shearing station, a product table, an electrical system, and a hydraulic system. These components work together to ensure efficient ceiling T grid production.

● Design Features of Ceiling T Grid Machine

1) Raw material adaptability for ceiling t bar machine

The newly designed ceiling t bar machine is specifically designed for both galvanized steel and pre-painted galvanized steel. These two materials are the most commonly used in ceiling T bar production, widely used in modern construction and decoration due to their excellent corrosion resistance and strength. Galvanized steel undergoes a galvanizing process to enhance its surface rust resistance and extend its service life, while pre-painted galvanized steel undergoes a coating treatment in addition to galvanizing, offering a wider range of color options and enhanced aesthetics.

During the design phase, KINGREAL engineers carefully considered the ceiling t grid machine's construction to ensure it could effectively handle both materials. The thickness ranges of 0.23-0.35mm for galvanized steel and 0.3-0.4mm for pre-painted galvanized steel, respectively, required the ceiling t bar machine's performance to be adaptable to the physical properties and processing requirements of the different materials. This meant that the ceiling t grid machine's rollers, cutting tools, and various transmission components required specialized design to prevent material deformation or excessive tool wear during processing.

2) Finished product types for ceiling t bar machine

Customizable ceiling t bar machines can produce a variety of product types, including main t, cross t, wall angle, and W-shaped profile, depending on the customer's specific needs. Different end products require different ceiling t grid machine components, so communication between KINGREAL engineers and customers is crucial during the design process. By understanding the customer's desired product type, KINGREAL can ensure optimal ceiling t bar machine performance.

Designing and manufacturing for different product types allows KINGREAL to provide more precise solutions to meet the customer's exact production needs.

3) Flexible specifications of ceiling t grid machine

Before designing, KINGREAL engineers will confirm the desired end product specifications with the customer. KINGREAL ceiling t bar machines can produce a variety of ceiling t bar sizes, such as 38x24mm and 38x15mm, using roller changers and cutting dies for adjustment. This flexibility allows the ceiling t grid machine to adapt to the customer's diverse production needs and meet market demand for diverse products. Here are some common ceiling t bar dimensions for your reference:

38H Model:

I) Main t: 38mm x 24mm x 3.0m, or 3.05m, 3.60m, or 3.66m

II) Cross t: 26mm x 24mm x 1.2m, or 1.22m

III) Cross t: 26mm x 24mm x 0.6m, or 0.61m

IV) Wall angle: 20mm x 20mm x 3.05m, or 3.60m; 22mm x 22mm x 3.05m, or 3.60m; 24mm x 24mm x 3.05m, or 3.60m

V) Thicknesses: 0.23mm, 0.25mm, 0.28mm to 0.30mm, and 0.40mm.

These various sizes and specifications provide customers with more options for installation and ceiling design, enhancing overall design flexibility and aesthetics.

4) Special needs for ceiling t bar machine

When communicating with customers, it is crucial to understand their specific needs. For example, during consultation, an Italian customer specifically stated that they required extended production runs. To address this need, KINGREAL engineers designed a high-end ceiling t grid machine equipped with an additional hydraulic oil cooling system. This system ensures that the ceiling t bar machine will not overheat during extended periods, improving reliability and durability.

Additionally, certain customers may have additional requirements for surface treatment, corrosion resistance, and wear resistance. In these cases, KINGREAL will make design adjustments based on customer feedback to ensure the final product fully meets their expectations.

5) Production speed optimization for ceiling t grid machine

To meet the efficient production needs of Italian and North American customers, KINGREAL designed the ceiling t bar machine with a maximum operating speed of 30m/min. Customers can adjust the speed via the PLC control panel to meet diverse production needs. This flexibility allows the ceiling t grid machine to adapt to various production environments and enhances ease of use.

Higher production speeds not only increase output but also reduce unit production costs. By adjusting the speed appropriately, customers can flexibly adjust production plans based on order requirements, ensuring timely delivery even during peak periods.

(Italy ceiling t bar machine project)

● Technical Specifications of Ceiling T Bar Machine

| NO. | Name | Specification |

1 | Roller | 16 Rows Material:Cr12 roller inner diameter:Φ40mm roller outer diameter:minΦ90 heat treatment hardness:HRC58-62 |

| 2 | Transmission | 3kw. chain drive + gear transmission |

| 3 | Side Plate | Thickness 25mm, grinding six-sided, high-precision boring from processing |

| 4 | axle | Material:45# steel,Machine tool processing heat treatment,then grinding machine finished |

| 5 | Feeding Possitioning | Manual positioning, flexible adjustment at both ends |

| 6 | PLC | PLC programming controller, with the touch screen automatic control system |

| 7 | Stamp Die | Material:SKD11,heat treatment hardness:HRC56-58 |

(The above specifications are for reference only. KINGREAL will design the ceiling t grid machine based on customer drawings and actual requirements.)

Advantages of Ceiling T Bar Machine

1. Multiple ceiling t bar machine manufacturing solutions

KINGREAL offers a variety of ceiling t grid machines capable of producing a variety of finished products, including flat ceiling t bar, center black line ceiling t bar, silhouette groove ceiling t grid, and FUT ceiling t grid. Furthermore, KINGREAL ceiling t bar machine can be configured in both fully automated and semi-automated configurations to meet diverse production requirements.

2. Complete ceiling t grid machine solutions

In addition to ceiling t bar machines, KINGREAL also offers complete LAY-IN metal ceiling tile production lines. Ceiling t bar produced by the ceiling t grid machine is combined with metal ceiling panels produced by the lay in metal ceiling tile production line to create a complete ceiling system. This integrated solution not only improves production efficiency but also reduces procurement costs.

3. Excellent customer service

KINGREAL values customer feedback and needs. KINGREAL team of engineers maintains constant communication with customers, ensuring timely response to their comments and suggestions throughout the design and production process. KINGREAL also provide comprehensive after-sales service. Upon arrival of the ceiling t bar machine, KINGREAL professional engineers will provide installation and operation training, ensuring that customers receive technical support and maintenance services throughout their operation.

(North America ceiling t grid project)

Both ceiling t grid machines have now been completed, and KINGREAL will invite customers from Italy and North America to personally inspect them!