Technological Innovation: Ceiling Gypsum Board Frame Machine

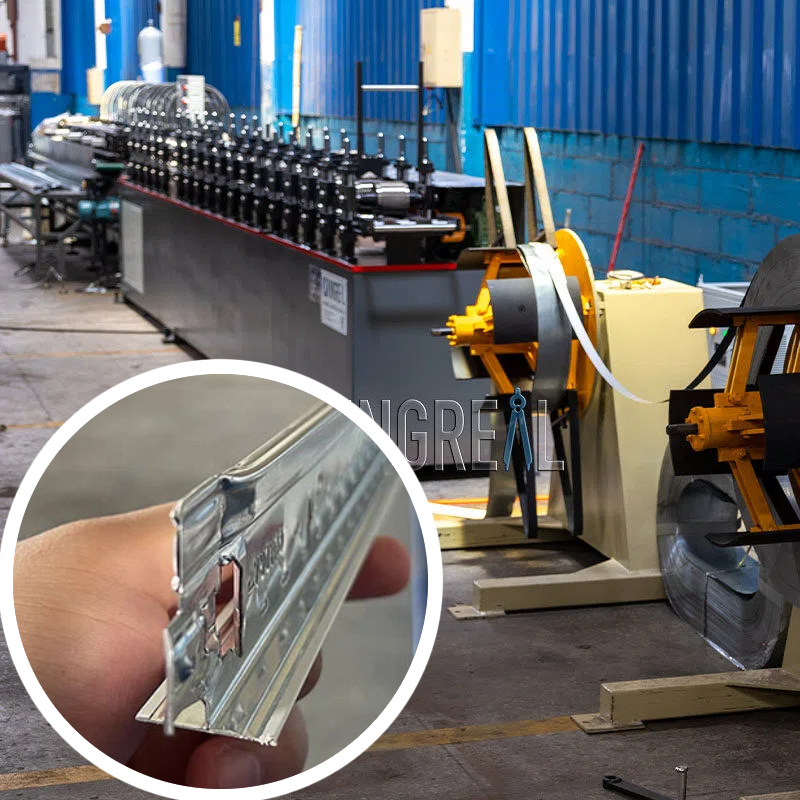

2025-10-19 12:00With the continuous development of the construction industry, renovation teams are increasingly demanding ceiling gypsum board frame machines. KINGREAL gypsum board ceiling tee grid machines, with their efficient automated performance of 30m/min, are the preferred choice for many construction and renovation teams, producing a variety of ceiling t grid sizes and types, including flat t grid, center black line t bar, FUT ceiling t grid, silhouette groove ceiling t grid.

KINGREAL has extensive experience in the design and manufacture of ceiling gypsum board frame machines and has collaborated on gypsum board ceiling tee grid machine projects with clients in countries including Brazil, Saudi Arabia, the Dominican Republic, Bangladesh, Russia, India, Indonesia, and Vietnam. As the market evolves and customer needs diversify, KINGREAL continues to innovate ceiling gypsum board frame machines to meet evolving production needs.

Integrated Punching and Shearing Design

KINGREAL engineers have designed a unique integrated punching and shearing system for the gypsum board ceiling tee grid machine, enabling the punching and shearing of metal coils to be completed in a single step, significantly improving production efficiency. Traditional production methods typically require the metal coils to be punched and cut separately, which is not only time-consuming but also potentially results in material waste between the different steps. KINGREAL integrated punching and shearing design effectively integrates these two processes, making the production process more efficient and streamlined.

In addition, this integrated punching and shearing design allows customers to flexibly adjust production parameters based on their specific needs. Whether it's ceiling t bar of varying sizes or different types of materials, the gypsum board ceiling tee grid machine can easily handle and quickly switch between them.

Safety Shield for Ceiling Gypsum Board Frame Machine

To meet the safety requirements of various countries for mechanical equipment, as well as the strong demand for production safety from many customers, KINGREAL has equipped gypsum board ceiling tee grid machine with a safety shield.

While the ceiling gypsum board frame machine is operating, workers no longer need to worry about being injured by accidentally touching the moving rollers. The safety shield effectively prevents direct contact between workers and the moving equipment through physical isolation. This design provides a safe working environment, which is particularly crucial during high-intensity production.

The safety shield is also designed for easy maintenance and cleaning. When the gypsum board ceiling tee grid machine is not in operation, workers can open the shield at any time for cleaning and routine maintenance. This design not only extends the ceiling gypsum board frame machine's service life but also reduces the risk of failure due to improper maintenance.

Hydraulic Oil Cooler for Gypsum Board Ceiling Tee Grid Machine

In some high-temperature regions, such as Saudi Arabia, temperatures can reach 40°C or even higher. Under such conditions, normal ceiling gypsum board frame machine operation can be challenging, particularly with overheating of the hydraulic system. To address this challenge, KINGREAL engineers proposed equipping the gypsum board ceiling tee grid machine with a hydraulic oil cooler. This technology effectively reduces the temperature of the hydraulic oil, ensuring continuous and stable operation in high-temperature conditions and producing high-precision finished products.

The introduction of a hydraulic oil cooler not only improves equipment reliability but also meets customers' production needs in extreme climates. In high-temperature environments, excessively high hydraulic oil temperatures can easily degrade hydraulic system performance and even cause equipment failure. The cooler effectively controls the hydraulic oil temperature within a reasonable range, maintaining normal ceiling gypsum board frame machine operation. This design takes into account customers' actual operating environments and greatly enhances the applicability of KINGREAL gypsum board ceiling tee grid machine, providing customers with a more stable and efficient production experience.

Complete Suspended Ceiling System Solutions

KINGREAL is committed to providing customers with a complete suspended ceiling system solution. In addition to ceiling gypsum board frame machines, KINGREAL also offers open cell ceiling grid machines, metal ceiling tile production line, and ceiling t grid wall angle machine to meet customers' diverse needs for complete suspended ceiling systems. This one-stop service not only improves purchasing efficiency but also ensures compatibility between equipment, greatly streamlining the production process. By combining these suspended ceiling making machines, customers can achieve a perfect solution for their suspended ceiling system installation projects. Furthermore, KINGREAL can offer customers multiple machines simultaneously, ensuring the convenience and consistency of purchasing equipment from the same manufacturer and reducing the complexity of ongoing maintenance and technical support.