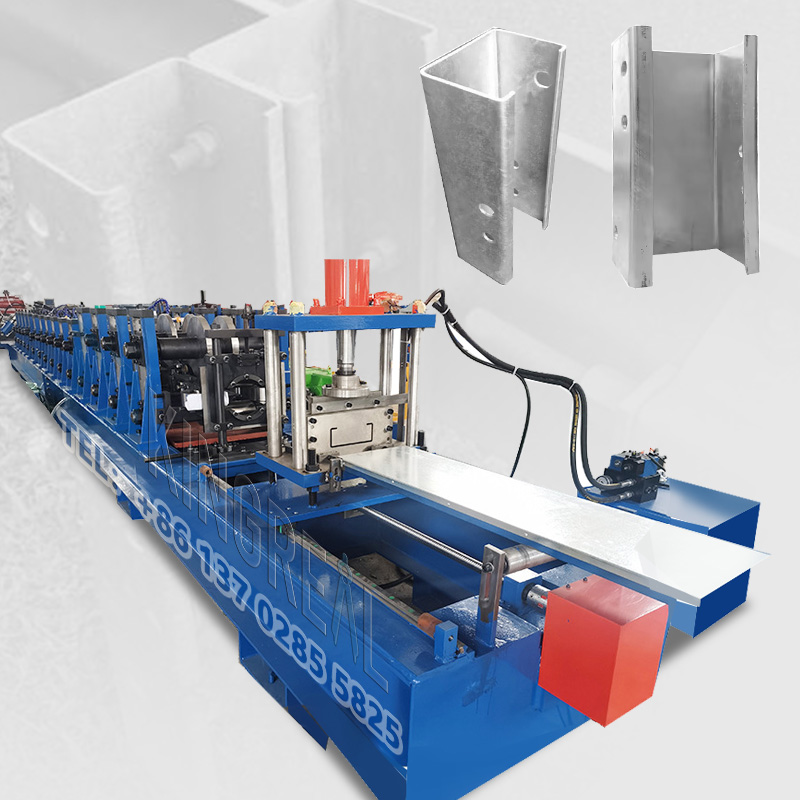

C Post Roll Forming Machine

KINGREAL c post roll forming machines are used to produce guardrail c posts, typically 3-6 mm thick. KINGREAL offers guardrail c post making machines with different parameters and performance to meet the diverse production needs of customers in highway guardrail projects.

- KINGREAL MACHINERY

- China

- Information

- Download

Description of Highway C Post Roll Forming Machine

Highway c post roll forming machine is specifically designed for producing C-shaped posts, typically 3-6 mm thick. C posts manufactured by KINGREAL guardrail c post making machines serve as supports for beam-type guardrails, bearing crucial protective performance and effectively preventing damage from vehicle collisions. Proper installation of guardrail posts is not only essential for the functionality of the guardrail but also a vital aspect of ensuring traffic safety.

Furthermore, c posts produced by KINGREAL highway c post roll forming machines have a long service life. Their surface is typically treated with hot-dip galvanizing or powder coating to enhance rust and corrosion resistance. This design ensures the stability and durability of the c posts in various harsh environments. Depending on customer needs, KINGREAL guardrail c post making machines offer both flanged and flangeless post types. Flangeless guardrail posts are typically used for installation on soft soil, while flanged posts are suitable for concrete pavements and can be easily secured to the desired location using long bolts.

KINGREAL not only provides highway c post roll forming machines but also highway guardrail roll forming machines and other equipment, aiming to meet customers' diverse equipment needs in highway guardrail projects. KINGREAL engineers will provide customized guardrail c post making machine solutions based on customer-provided drawings, tolerances, and budgets, ensuring that each customer's unique requirements are met.

Working Process of Highway C Post Roll Forming Machine

Hydraulic decoiler with cart→Hydraulic feeding table→Leveling unit—>Hydraulic Punch Station with the pre-cutting unit→Roll forming machine→Servo tracking cutting→Output table

Parameters of Guardrail C Post Making Machine

C Post Roll Forming Machine | ||

Machinable Material | A) Galvanized Steel | Thickness(MM): 3.0-6.0 mm Or According To Customer |

B) PPGI | ||

C) Carbon Steel | ||

Yield Strength | 250 – 550 Mpa | |

Tensile Stress | G250 Mpa-G550 Mpa | |

Decoiler | Hydraulilc Decoiler | |

Punching System | Hydraulic Punching Station | |

Forming Station | About 12 – 16 Stations | * According To Your Profile Drawings |

Driving System | Gearbox Drive | |

Machine Structure | Forged Iron Station | |

Forming Speed | 0-20 (M/MIN) | Not Including Cutting And Punching |

Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

Cutting System | Post-cutting | |

Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

PLC Brand | Panasonic | * Siemens (Optional) |

Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

Parameters of Guardrail Post Product

Size | 41.3mm * 47.6mm |

Thickness | 100 / 350 / 550 / 610 / 1100 / 1200 g/㎡; 15µm / 50µm / 77µm / 85µm / 140µm / 155µm or according to your requirements |

Surface Treatment | Hot-dip galvanized |

Fence Standard | EN 1317(European Standard) |

Installation | Bolted or driven installation |

Load Capacity | Designed to withstand specific impact loads according to highway safety standards |

Application | Designed for use in highway guardrail systems, supporting guardrail beams and absorbing impact energy |

Shape | Cross-sectional shape similar to the letter "C", Flanges on both sides provide structural stability |

Advantages of Highway C Post Roll Forming Machine

(1)Highly flexible guardrail c post making machine

KINGREAL highway c post roll forming machine boasts high flexibility, efficiently handling various types of metal with different thicknesses and widths. Whether producing c posts of varying heights and widths, or meeting specific project requirements and standards, KINGREAL provides suitable guardrail c post making machine manufacturing solutions.

(2)Precision control system for highway c post roll forming machine

KINGREAL guardrail c post making machine is equipped with a precise control system, ensuring accurate adjustments and consistently high-quality results in every production run. This precise control is crucial for maintaining production standards, guaranteeing that every post meets stringent quality specifications.

(3) Punching function for highway c post roll forming machine

KINGREAL guardrail c post making machine also features a hydraulic punching station, capable of customizing punching dies according to customer requirements for hole diameter. This function allows for pre-drilling of bolt holes during the guardrail post production process, facilitating rapid installation in highway guardrail projects. The automated punching design significantly improves production efficiency and reduces the complexity of manual operation.

Applications of highway c post roll forming machine

(1)Guardrail c post making machine in highways and expressways: Installing safety guardrails along highways to prevent vehicle collisions.

(2)Highway c post roll forming machine in urban roads and streets: Enhances the safety of urban environments by protecting pedestrians and vehicles.

(3)Guardrail c post making machine in industrial zones: Protects infrastructure and equipment in industrial environments from accidental vehicle impacts.

(4)Highway c post roll forming machine in bridges and overpasses: Ensures the stability and safety of elevated roads and buildings.

FAQ :About Guardrail C Post Making Machine

Q1:What thickness of material can this guardrail c post making machine process?

A1:This highway c post roll forming machine can process metal coils with thicknesses ranging from 3 mm to 6 mm, suitable for most guardrail post standards. For special production needs with thinner or thicker materials, please contact KINGREAL.

Q2:What is the guardrail c post making machine's production speed?

A2:Depending on the post design and material, this highway c post roll forming machine generally has a maximum production speed of 20 m/min.

Q3:Is the highway c post roll forming machine's punching and cutting system automated?

A3:Yes, the guardrail c post making machine uses hydraulic punching and precision cutting to ensure consistent post lengths.

Q4:How is the highway c post roll forming machine controlled?

A4:The guardrail c post making machine uses a PLC control system with a touchscreen interface for easy adjustment and monitoring.

Q5:What routine maintenance is required?

A5:The highway c post roll forming machine needs to be lubricated regularly, the rollers checked, the hydraulic system inspected, and the cutting blades replaced periodically.