Door Frame Making Machine

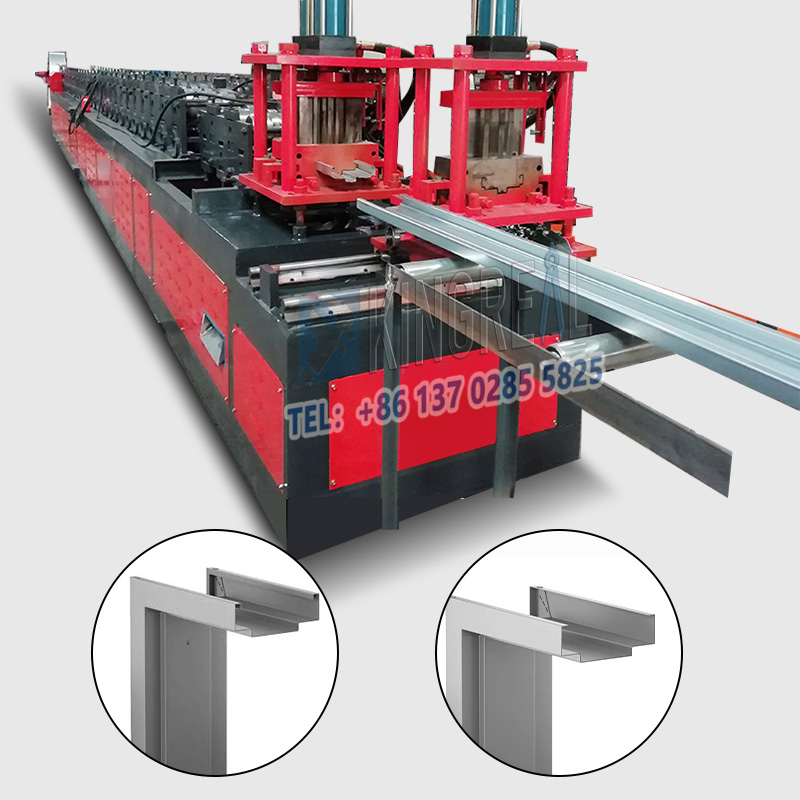

KINGREAL door frame machine is used to produce door frames of various sizes. This door frame making machine uses preset molds to accurately stamp and cut metal materials, thereby obtaining door frames of various shapes and sizes.

- KINGREAL

- China

- Information

- Download

Definition of Door Frame Roll Forming Machine

KINGREAL door frame machine is used to produce different sizes of door frames, characterized by high efficiency, precision, and stability. Using pre-set molds, the door frame making machine can precisely stamp and cut metal materials to obtain door frames of various shapes and sizes. Furthermore, this door frame machine is equipped with an advanced automatic feeding system, enabling continuous production and significantly improving production efficiency to meet the diverse market demands for door frames.

Working Process of Door Frame Machine

Decorator -- Leveling Machine -- Punching Station -- Roll Forming Machine -- Cutting Station -- Output

Parameters of Door Frame Making Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 0.8-13/1.0-1.6/1.5-2.0 (mm)

Forming Speed: 10-25 m/min

Maine power: 11 KW

Cut Lengths: 1000 – 6000 mm

Profile Width: 50 – 300 mm

Features of Door Frame Making Machine

1

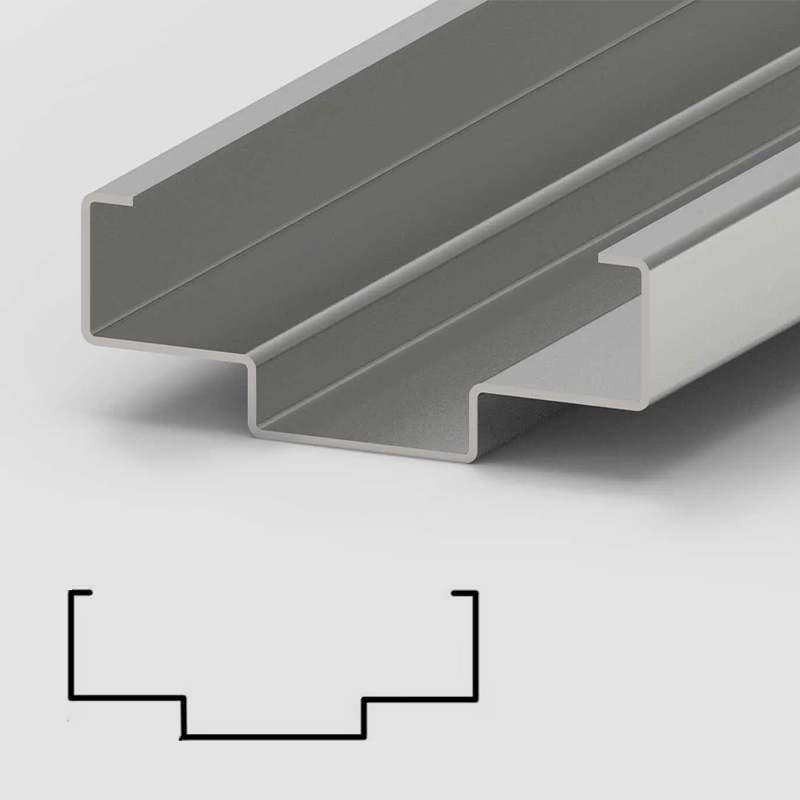

Multi-size door frame making machine

KINGREAL door frame roll forming machine can produce door frames of various sizes according to national standard forming widths, and also offers custom production. Common door frames with widths from 120mm to 250mm can be easily produced with just one door frame making machine. Customers can place orders according to specific needs.

KINGREAL door frame roll forming machines can always adapt to various wall structures and door sizes, ensuring wide applicability and flexibility.

2

Heavy duty door frame making machine

To manufacture robust and stable door frames, KINGREAL heavy-duty door frame roll forming machine is specially designed for high-load conditions. This door frame making machine can handle various materials such as galvanized steel, carbon steel, stainless steel, and copper, ensuring standardized forming even in the most demanding environments.

No matter how harsh the working conditions, the door frame roll forming machine ensures efficient operation and delivers superior product quality.

3

High-efficiency door frame roll forming machine

KINGREAL door frame making machine consists of automated precision components such as a decoiler, leveler, punching station, roll forming machine, and cutting station.

These components work together to ensure the continuity of the entire production process. Meanwhile, rollers mounted on 80mm diameter shafts enable various forming speeds to meet different production needs while ensuring product durability and stability.

Advantages of Door Frame Making Machine

1. Servo Feeding: The decoiler utilizes a servo motor, a design that allows for precise speed and tension control. During production, the servo motor ensures a uniform material supply, preventing product defects caused by uneven feeding and significantly improving production accuracy. This precise control maintains a high degree of consistency in the size and shape of the door frame.

2. Automatic Lubrication: Equipped with rollers featuring automatic lubrication, this significantly reduces the time and cost of manual maintenance. This design ensures that lubricant is precisely applied to the parts requiring lubrication, reducing wear and extending the door frame roll forming machine's lifespan. Simultaneously, a stable lubrication system guarantees the reliability of the door frame making machine during long-term operation, reducing malfunctions caused by lack of lubrication.

3. Quick Die Change: The door frame roll forming machine supports quick die change functionality, allowing for tool-free die replacement. This design significantly improves the profile changeover speed, enabling manufacturers to quickly adapt to different order requirements and increasing production flexibility.

4. Touchscreen HMI: The door frame making machine is equipped with a user-friendly touchscreen HMI, making production management simple and clear. Operators can quickly master the operation without complex training. The intuitive interface design significantly reduces the probability of operational errors and improves production efficiency. Furthermore, this interface not only facilitates setting and adjusting parameters but also displays real-time production status and efficiency data, helping managers make precise production scheduling and decisions.

Application of Door Frame Making Machine

KINGREAL door frame roll forming machines have a wide range of applications and can be highly customized to meet customer requirements. Metal door frames produced by KINGREAL door frame making machines are designed for uses ranging from shops to penthouse apartments, adapting to a wide variety of environments. In these applications, hollow steel door frames are widely used both indoors and outdoors, suitable for the structural requirements of commercial metal door frames. Steel and metal door frames are widely used in residential, apartment, and other locations with high strength requirements. Through the support and foundation construction of the door frame, various types of doors (such as sliding doors, glass doors, and wooden doors) can be effectively reinforced, ensuring safety and stability.

Related Products

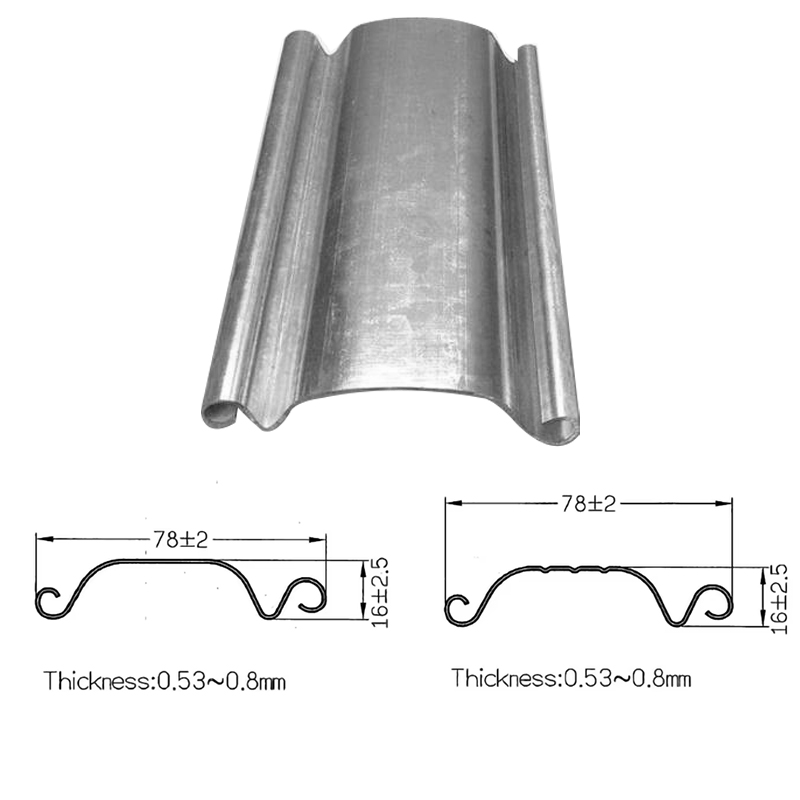

In the door industry, in addition to door frame roll forming machines, KINGREAL also offers various types of roll forming machines, including shutter door roll forming machines. This shutter door roll forming machine can not only produce various roller shutter doors but also perform additional functions such as punching and embossing. KINGREAL shutter door roll forming machines, with their excellent processing capabilities and flexibility, can meet diverse customer needs and provide perfect solutions for various types of buildings.

FAQ :About Door Frame Making Machine

Q1: Which alloys are suitable for door frames?

A1: Commonly used roll forming alloys include low-carbon steel, 304/316 stainless steel, and 6061 aluminum alloy. These materials all possess good strength and durability, providing lasting support for door frames.

Q2: What is the production capacity of this door frame making machine?

A2: Depending on the configuration, KINGREAL door frame roll forming machine can produce 8-15 meters of profile per minute, ensuring high production efficiency and consistent quality.

Q3: How does KINGREAL guarantee the precision of door frame manufacturing?

A3: KINGREAL door frame making machines are equipped with advanced CNC systems, high-quality rollers, and automated control systems, ensuring that the finished products have high precision, a smooth surface, and consistent dimensions.

Q4: What is the door frame roll forming machine's maximum production speed?

A4: Generally, the maximum production speed of KINGREAL door frame roll forming machines is 25m/min. For solutions requiring higher speeds, please contact KINGREAL; the KINGREAL team will provide you with specific advice.