Highway Sound Barrier Wall Panel Machine

Highway sound barrier wall panel machines are specifically designed for the production of sound barriers. These noise barrier roll forming machines typically use galvanized steel, aluminum, and pre-coated rolls with a thickness of 0.3-1.2mm as the main raw materials. The sound barriers produced are widely used in highway and railway sound insulation projects, effectively providing sound insulation.

- KINGREAL

- China

- Information

- Download

Definition of Highway Sound Barrier Wall Panel Machine

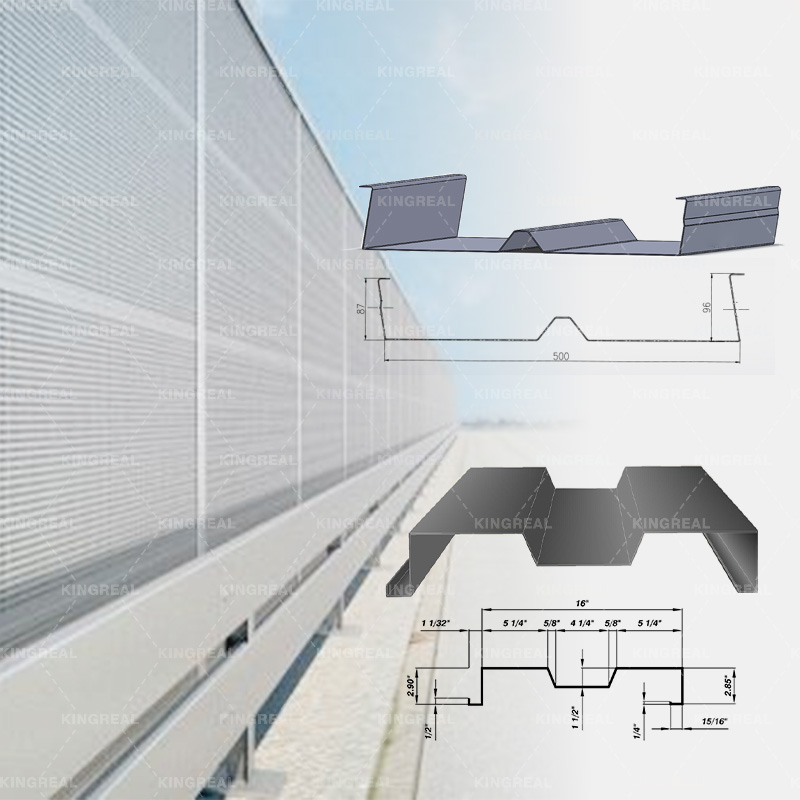

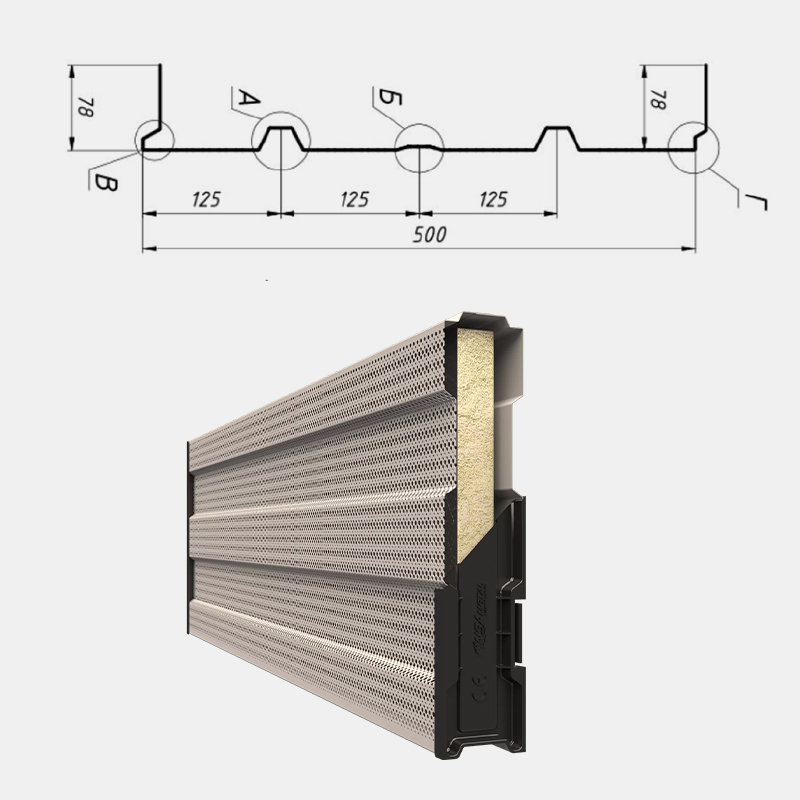

Highway sound barrier wall panel machines are specifically designed to produce high-precision sound barriers with a scratch-free surface. These noise barrier roll forming machines typically use galvanized steel, aluminum, and pre-coated coils with a thickness of 0.3-1.2mm as the main raw materials. These highway sound barrier wall panel machines integrate a punching unit, capable of creating perforations of various shapes, including round, square, and custom patterns, to enhance sound absorption. Noise barriers of different specifications produced by these highway sound barrier wall panel machines are widely used in highway and railway sound insulation projects, effectively providing sound insulation.

This noise barrier roll forming machine consists of multiple precision components, including an decoiler, leveling machine, feeding system, punching machine, main roll forming machine, and cutting station. This highway sound barrier wall panel machine boasts advantages such as high production speed, low labor requirements, and fine workmanship, effectively improving production efficiency and reducing operating costs for customers.

◤Working Process of Highway Sound Barrier Wall Panel Machine◥

Decoiler--Leveling Machine--Punching Machine--Roll Forming Machine--Cutting Station--Output Table

Parameters of Highway Sound Barrier Wall Panel Machine

Feature | Details |

Panel Width | Adjustable according to project needs |

Punching Options | Variable width, shape, hole pattern |

Rolling Speed | 15–25 meters per minute |

Transmission System | Gearbox drive |

Frame Thickness | 35mm solid steel plates |

Roller Material | GCr12Mov, heat-treated |

Motor System | Siemens motor + servo motor drive |

Bearings | High-quality SKF bearings |

Cutting System | Servo-tracking shear, highly accurate |

Main Components of Noise Barrier Roll Forming Machine

(1) Feed guide roller for noise barrier roll forming machine

-Positioning Roller: Used to adjust the position of both ends of the material to match the feed width, ensuring the accuracy of material transmission.

-Guide Roller: Through the design of upper and lower circular rollers, the material is fed more smoothly, avoiding material jamming.

-Feeding Rollers: Ensure the flat conveying of material rolls, preventing folding and deformation, thus improving the precision of subsequent processing.

-Pneumatic Devices: Equipped with eight pneumatic devices, automatically adjusting the distance between the upper and lower shafts to ensure stability during production.

(2) Roller assembly for highway sound barrier wall panel machine

-Main Shaft Diameter: Made of φ80mm 45# round steel to ensure structural stability.

-Roller Material: Heat-treated and precision-machined, then hard chrome plated and mirror-polished to greatly enhance wear resistance.

-Machine Base Tie Rod: Made of φ20# electroplated round steel to increase the rigidity of the noise barriers on both sides and improve the overall strength of the highway sound barrier wall panel machine.

-Cold Bending Forming: A series of cold bending forming processes ensure the precision of each sound barrier.

(3) Precision cutting for highway sound barrier wall panel machine

-Guiding Mechanism: The cutting blade can smoothly cut, ensuring no deformation of the cut and improving the dimensional accuracy of the finished product.

-Cast Iron Blade Holder: Provides significant shock absorption, effectively reducing impact and extending the tool's lifespan.

-Blade Material: Cr12Mov material, with a shearing life exceeding 1 million cycles, significantly reducing replacement frequency.

-Rear Shear Frame: Made of Q235 steel plate, rough milled and annealed to ensure stability after finishing.

(4) PLC control cabinet for noise barrier roll forming machine

-PLC System: Employs a high-precision Delta/Schneider PLC electrical control system to ensure control accuracy and stability.

-Frequency Inverter: Delta/Schneider heavy-duty frequency inverters maintain stable operating efficiency even under high load conditions.

-Control Components: Schneider Electric components have a long service life and low failure rate, ensuring the machine's long-term stable operation.

-Touchscreen Operation: By inputting production data via the touchscreen, the highway sound barrier wall panel machine can automatically complete specific production requirements, simplifying the operation process.

Advantages Of Noise Barrier Roll Forming Machine

(1)High-speed highway sound barrier wall panel machine

The noise barrier roll forming machine can achieve a forming speed of up to 25m/min. Customers can flexibly adjust the highway sound barrier wall panel machine's operating speed according to the actual needs of different projects, ensuring effective operation even during peak periods and special circumstances, helping enterprises maximize production efficiency.

(2)Multi-stage roll forming for highway sound barrier wall panel machine

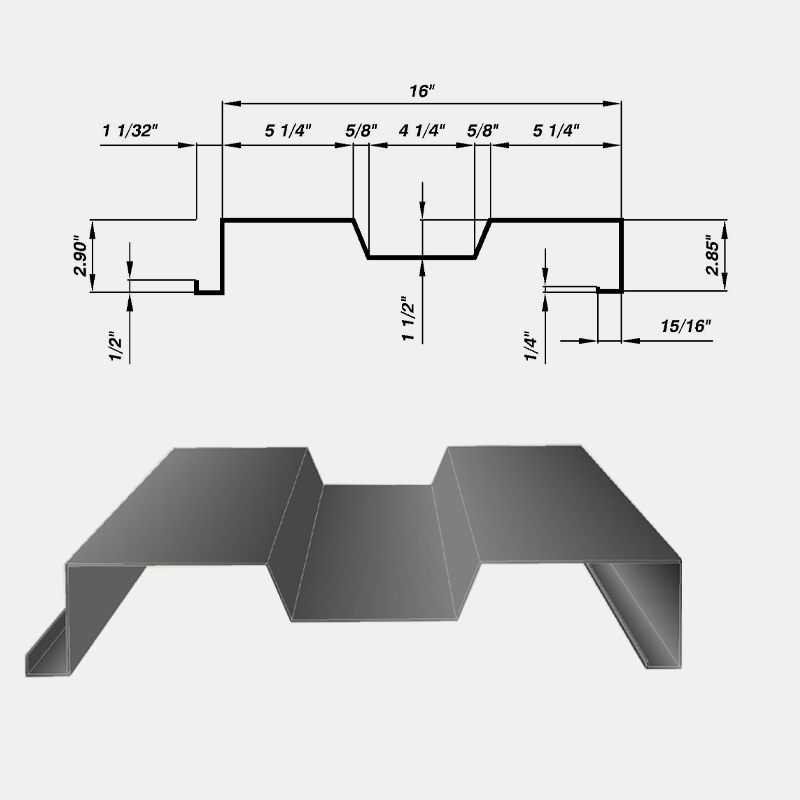

The noise barrier roll forming machine adopts an advanced multi-stage roller assembly design. Through precise roll forming technology, it processes metal coils into highway sound barrier wall panel frames of various specifications and styles. Roll forming not only improves product precision but also ensures that each noise barrier has a smooth and flawless appearance, meeting the high-quality market demands. Furthermore, through reasonable roller arrangement and process design, the shape and specifications of the highway sound barrier wall panel perfectly match design requirements after multi-stage forming.

(3)Material compatibility for noise barrier roll forming machine

This highway sound barrier wall panel machine can adapt to the processing needs of various metal materials such as galvanized steel, aluminum, and stainless steel. It allows customers to flexibly choose materials according to different market demands and customer preferences, while also greatly expanding the application range of the noise barrier roll forming machine.

(4)Customized highway sound barrier wall panel machine

KINGREAL noise barrier roll forming machines excel in customized production, capable of producing various types of highway sound barrier wall panels, such as perforated, slotted, or solid back panels, based on customer design drawings. This high degree of customizability perfectly meets the special needs of different customers.

(5) Automatic cutting/punching for noise barrier roll forming machine

The highway sound barrier wall panel machine features automatic cutting and punching functions via a PLC control panel, enhancing the automation level of the production line. This technology not only improves production efficiency but also ensures length accuracy up to ±0.5 mm.

(6) Low maintenance costs for noise barrier roll forming machine

Compared to similar highway sound barrier wall panel machines on the market, KINGREAL noise barrier roll forming machine significantly reduces maintenance costs due to its durable rollers and low-energy design. This effectively helps customers control production costs and improve return on investment. Furthermore, the durable highway sound barrier wall panel machine avoids frequent repairs and parts replacements, ensuring long-term stable production for customers.

Applications of Highway Sound Barrier Wall Panel Machine

The highway sound barrier wall panels produced by KINGREAL noise barrier roll forming machine are widely used in facilities near residential areas, such as highways, railways, and airports. These panels are used in the construction of noise barriers, effectively reducing vehicle noise pollution and minimizing the impact on nearby communities.

The unique design of the noise barrier (such as the densely packed conical bottom and elliptical micro-pores on the bottom surface, and the wave-shaped surface formed on the top surface) allows reflected sound waves to attenuate due to mutual collision and interference. Even if some sound waves penetrate through the elliptical micro-pores, there will be a loss in sound wave penetration, thus achieving a better sound absorption effect. This demonstrates the high level of technology and innovation of the highway sound barrier wall panel machine.In addition, this noise barrier also has fireproof, high strength, and waterproof and dust-proof characteristics, which has led to its widespread application and recognition in the market.

KINGREAL Exhibition