Highway Guardrail Roll Forming Machine

▷KINGREAL Highway Guardrail Roll Forming Machine◁ can produce various guardrails for highways. One highway guardrail roll forming machine can produce multiple specifications, effectively improving production efficiency and cost-effectiveness for customers.

- KINGREAL

- Information

- Download

What is Highway Guardrail Production Line?

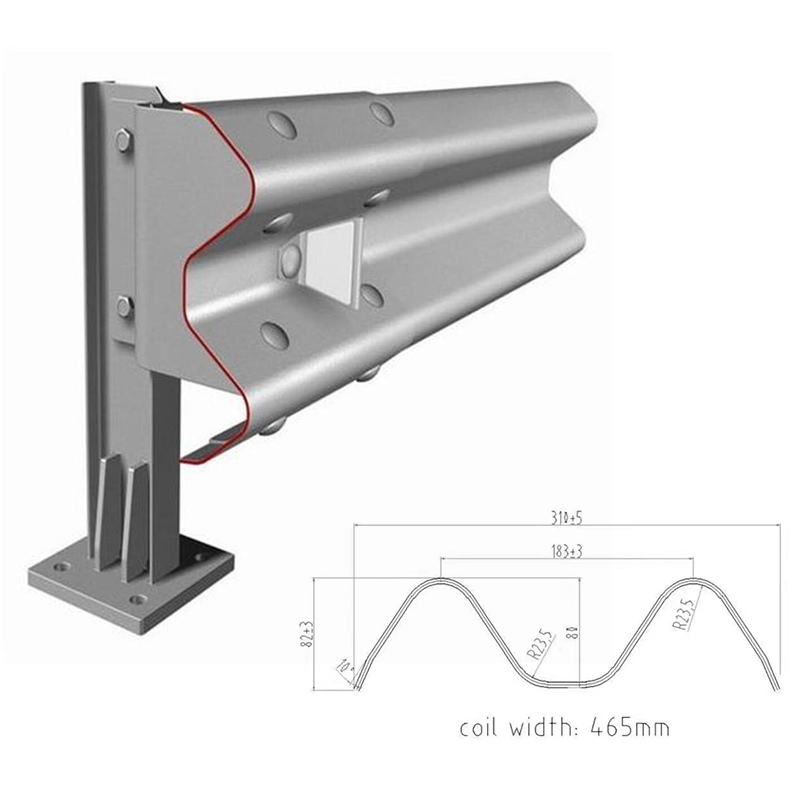

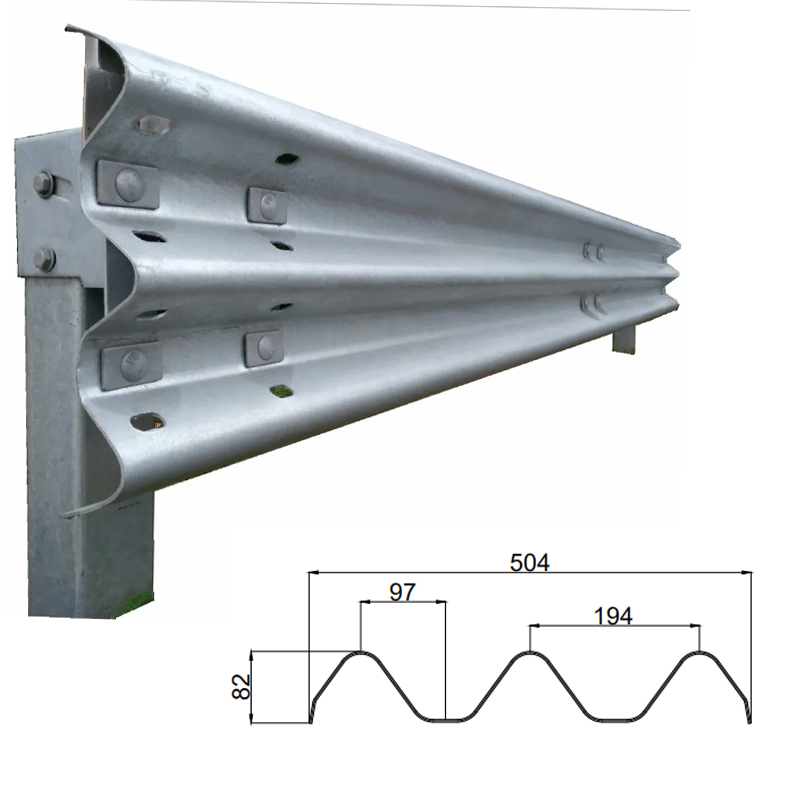

Highway guardrail Roll Forming Machine are specifically designed for producing highway guardrails. These highway guardrail roll forming machines can form various metal raw materials, such as galvanized steel, PPGI, and carbon steel, into precise guardrail profiles, commonly including 2 & 3 waves w-beam highway guardrails. The core components of a highway guardrail Roll Forming Machine include a hydraulic decoiler, leveling system, hydraulic feeding device, hydraulic press (with molds), hydraulic punching station (with pre-cutting unit), roll forming machine, hydraulic cutting unit, discharge table, hydraulic oil pump, and electrical control cabinet. The combination of these precision components enables the highway guardrail roll forming machine to not only have high production capacity but also ensure the precision and quality of the finished product.

It is worth mentioning that KINGREAL highway guardrail Roll Forming Machine belong to the heavy-duty roll forming machine series. Therefore, KINGREAL uses higher precision manufacturing processes and high-quality forming molds and materials to ensure that it can provide customers with high-quality highway guardrail roll forming machine and produce high-precision highway guardrails. Highway guardrails are used along roadsides including curves, ramps, parking lots, intersections, and dead ends, effectively reducing the number and severity of accidents and ensuring road traffic safety.

Highway Guardrail Roll Forming Machine Parameters

Highway Guardrail Roll Forming Machine | |||

No. | Item | Specification | Optional |

1 | Suitable material | Galvanized, PPGI, Carbon steel, etc | |

Thickness(mm):4-5 | |||

Yield strength: 250 - 550MPa | |||

Tensile stress( Mpa):G350Mpa-G550Mpa | |||

2 | Nominal forming speed(m/min) | 15 | Or according to your requirement |

3 | Forming station | 12-15 | According to your profile |

4 | Decoiler | Hydraulic decoiler | |

5 | Main machine motor | Sino-German Brand | Siemens |

6 | PLC brand | Panasonic | Siemens |

7 | Inverter brand | Yaskawa | |

8 | Driving system | Gearbox drive | Chain drive |

9 | Rollers’ material | Cr12 | GCr15 or #45 Steel |

10 | Station structure | Forged Iron station | Wall panel station Or torri stand structure |

11 | Punching system | No | Hydraulic punching station or Punching press |

12 | Cutting system | Post-cutting | Pre-cutting |

13 | Power supply requirement | 380V 60Hz | Or according to your requirement |

14 | Machine color | Industrial blue | Or according to your requirement |

What Can KINGREAL Highway Guardrail Roll Forming Machine Do?

KINGREAL highway guardrail roll forming machines have multiple production capabilities, capable of manufacturing common 2 & 3 waves guardrails. While various countries have standardized requirements for the shape of highway guardrails, different countries have different thickness restrictions. For example, some countries limit guardrail thickness to 3 mm, while others accept 2 mm thick highway guardrails. KINGREAL highway guardrail roll forming machines can be designed to meet the customer's actual production needs, combined with the policy requirements of the customer's country.

KINGREAL highway guardrail production lines can produce the most widely used W-beam guardrails. If customers have special shape and size requirements, KINGREAL engineers will assist customers in custom designing according to drawings to ensure that the highway guardrail roll forming machine produces highway guardrails that meet specific needs.

Customized Highway Guardrail Roll Forming Machine Solutions

KINGREAL offers a variety of highway guardrail roll forming machine solutions, covering aspects such as raw material selection, thickness, shape design, punching, production speed, and drive system selection.

1. Different drive systems for highway guardrail production line

KINGREAL has designed an economical highway guardrail roll forming machine with a sprocket drive system, suitable for producing 2mm thick highway guardrails. For customers requiring thicker materials, KINGREAL also offers highway guardrail production lines equipped with gearboxes and universal joint shaft drive systems, capable of processing 3-4mm thick materials.

2. Different roll forming structures for highway guardrail production line

To meet different production needs, KINGREAL offers two highway guardrail roll forming machine solutions: an integrated forming frame and a split forming frame. The integrated forming frame is suitable for 2-3mm thick materials, while the split forming frame is suitable for 2-4mm thick materials. This flexible architecture design allows customers to choose the most suitable highway guardrail roll forming machine according to their needs, improving production efficiency.

3. Different punching dies for highway guardrail production line

To meet customers' diverse needs for the shape and diameter of holes in highway guardrails, KINGREAL offers customized punching dies. These personalized dies ensure that the highway guardrails produced by the highway guardrail production line possess high precision and burr-free characteristics, thereby further improving product quality and service life.

Q&A About Highway Guardrail Roll Forming Machine

Q1: How do you ensure that you can provide suitable highway guardrail roll forming machines for customers in different countries and regions?

A1: KINGREAL has accumulated extensive experience in the design and manufacture of highway guardrail roll forming machines and has a deep understanding of the usage standards for highway guardrails in various countries. Therefore, KINGREAL highway guardrail production lines are designed according to the requirements of different countries and regions, ensuring that the finished products meet multiple international standards such as AASHTO M180 (US guardrail standard), RAL RG620 (German guardrail standard), BS EN-1317 (European guardrail standard), AS/NZS 3845:1999 (Australian guardrail standard), and EN 1461:2009 (Turkish guardrail standard).

Q2: Can W-beam and three-beam guardrails be produced on one highway guardrail roll forming machine?

A2: Yes. The operator only needs to change the forming rollers at the last five forming stations of the highway guardrail roll forming machine. The entire process takes no more than 30 minutes, enabling rapid production of different guardrail types.

Q3: What is the speed of your highway guardrail production line?

A3: The highway guardrail roll forming machine's operating speed mainly depends on the production drawings, especially the stamping drawings. Generally, the linear speed is about 15 m/min, which can efficiently meet the needs of large-scale production.

Q4: How do you control the precision and quality of your highway guardrail production line?

A4: KINGREAL has its own factory, and all mechanical parts, including punching dies and forming rollers, are independently manufactured in the KINGREAL factory. Furthermore, KINGREAL has a dedicated team responsible for every aspect from design, processing, assembly to quality control, ensuring that every highway guardrail roll forming machine achieves high standards of precision and quality.