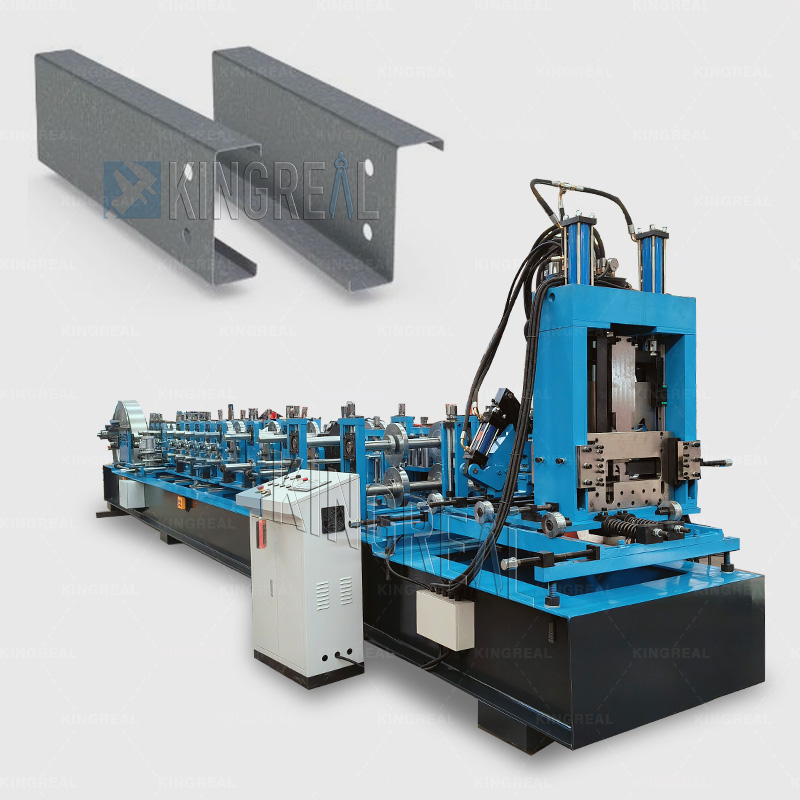

Heavy Duty Purlin Making Machine

KINGREAL is committed to providing high-performance heavy duty purlin making machines to meet diverse production needs and applications. KINGREAL heavy duty purlin roll forming machines not only feature fast and convenient c purlin and z purlin switching functions, but can also produce c purlin and z purlin of all specifications in the industry. This allows customers to respond more flexibly to different needs in construction projects, ensuring the safety and stability of the building structure.

- KINGREAL

- China

- Information

- Download

Introduction to Heavy Duty Purlin Making Machine

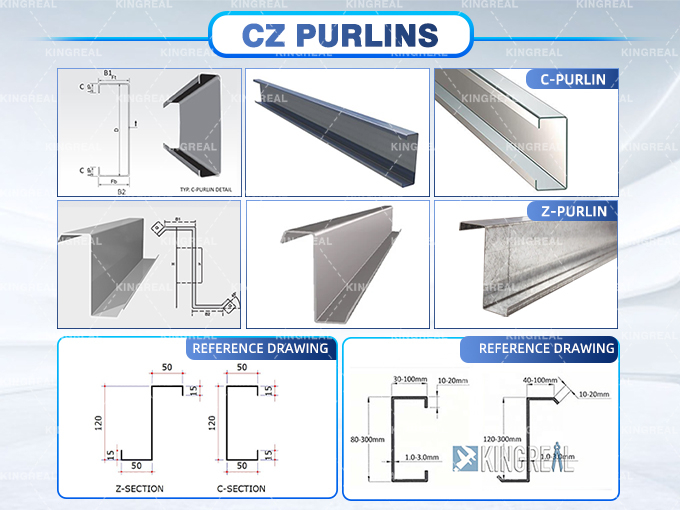

KINGREAL heavy duty purlin making machine is specifically designed for the production of c purlin and z purlin, which are mainly used as supporting horizontal beams or rods in building structures. Purlins of different specifications are used in industrial buildings, factories, warehouses, and agricultural projects. The specifications of the purlins are usually determined according to the roof span and load requirements, with a common thickness range of 1.2 to 4.0 mm, including different materials such as standard grade, reinforced grade, and special grade. Standard grade purlins are suitable for conventional factory building construction. In coastal areas, an additional thickness of 0.3 mm is usually required to resist corrosion from salt spray and other environmental factors.

Working Process of Heavy Duty Purlin Making Machine

Decoiler — Feeding and guiding table — Metal leveling machine — Punching machine — Roll forming machine — Cutting station — Output table

Parameters of Heavy Duty Purlin Roll Forming Machine

1. Decoiler: 3 tons/5 tons motor/hydraulic motor/passive (optional)

2. Feeding table

3. Leveling machine

4. Punching machine: According to profile requirements

5. Forming machine: 12-15 meters/minute

6. Safety cover: Optional

7. Cutting station

8. Output system: Manual support/automatic stacking machine (optional)

Stacking machine: (Output direction) Transverse/Longitudinal (optional)

9. Hydraulic system: Power supply for punching/post-cutting system

10. Electrical control system: Mitsubishi/Siemens/AMS (optional or customized as needed)

Heavy Duty Purlin Making Machine for Heavy Materials

KINGREAL heavy duty purlin roll forming machine can efficiently process heavy metal materials, producing high-precision, high-strength purlins, providing solid support and reinforcement for roof structures and walls. This heavy duty purlin making machine is specifically designed for industries that require processing thick metal materials, effectively meeting demanding application needs. These heavy duty purlin roll forming machines can handle thicker, higher-strength materials, such as structural steel, demonstrating exceptional processing capabilities.

The robust design of the heavy duty purlin making machine ensures stable performance under extreme loads. Furthermore, equipped with advanced hydraulic and control systems, it meets the demands of heavy-duty work in terms of precision, durability, and high productivity. Standard models can process materials up to 3.2 mm thick, while KINGREAL can also customize heavy duty purlin roll forming machine to process materials up to 5 mm thick for special needs. This fully automated heavy duty purlin making machine efficiently and continuously produces c purlin and z purlin with precise cutting, punching, and forming functions, making it an ideal choice for large construction projects.

Advantages of Heavy Duty Purlin Making Machine

Automated conversion for heavy duty purlin making machine

KINGREAL heavy duty purlin roll forming machine achieves automated production of various specifications of c purlin and z purlin. The c purlin specification conversion is fully automated, extremely easy to operate, and highly efficient. Simply enter the parameters on the display screen in seconds, and the control system will automatically adjust to the required specifications.

Customized heavy duty purlin making machine solutions

Based on the actual needs of customers, KINGREAL has designed various solutions with different parameters and performance for the heavy duty purlin roll forming machine. KINGREAL offers two design options for the heavy duty purlin roll forming machine: gearbox drive and chain drive. Gearbox drive is more suitable for applications requiring high precision and stability, especially when processing thicker materials, where the production volume will offset the higher initial cost. Chain drive is suitable for lighter operations, scenarios with limited budgets, or where material thickness and precision requirements are not high, providing greater cost-effectiveness. In addition, KINGREAL can also equip the heavy duty purlin roll forming machine with protective covers, stackers, and other components to further enhance operational safety and factory production efficiency.

Common Sizes of C and Z Purlins

C purlin:

Size (inches) | Size (mm) | note |

2 x 3 | 50 x 75 | One of the common sizes |

2 x 4 | 50 x 100 | One of the common sizes |

2 x 6 | 50 x 150 | One of the common sizes |

2 x 8 | 50 x 200 | One of the common sizes |

4 x 4 | 100 x 100 | Suitable for heavier loads |

4 x 6 | 100 x 150 | Suitable for heavier loads |

6 x 4 | 150 x 100 | Suitable for larger spans |

6 x 6 | 150 x 150 | Suitable for larger spans |

8 x 8 | 200 x 200 | Suitable for extra-large spans |

Z purlin:

Size (inches) | Size (mm) | note |

2 x 3 | 50 x 75 | One of the common sizes |

2 x 4 | 50 x 100 | One of the common sizes |

2 x 6 | 50 x 150 | One of the common sizes |

2 x 8 | 50 x 200 | One of the common sizes |

4 x 4 | 100 x 100 | Suitable for heavier loads |

4 x 6 | 100 x 150 | Suitable for heavier loads |

6 x 6 | 150 x 150 | Suitable for larger spans |

8 x 6 | 200 x 150 | Suitable for extra-large spans |

Application of Heavy Duty Purlin Roll Forming Machine

C purlin and z purlin produced by KINGREAL heavy duty purlin making machines are typically made of cold-rolled or hot-dip galvanized steel sheets, and are especially suitable for building structures that bear heavy loads.

Z purlins: Mainly used in large industrial plants, warehouses, bridges, etc. The strength and stability of these purlins allow them to meet the structural requirements of large buildings, effectively resisting wind and rain erosion and extending their service life.

C purlins: Suitable for light-duty buildings, such as residential buildings, commercial buildings, and light industrial plants. C purlins are not only cost-effective and lightweight, making them easy to process and install, but they are also suitable for large-scale production and rapid construction. They can also be used for decorative materials such as partition walls and ceilings.

Customers at KINGREAL Factory

KINGREAL warmly welcomes customers from all over the world to visit the KINGREAL factory. To date, KINGREAL has hosted customers from Morocco, the United States, Brazil, Russia, and many other countries for factory tours and heavy duty purlin roll forming machine demonstrations. At the KINGREAL factory, customers can directly observe the heavy duty purlin roll forming machines in operation and inspect the finished products to better assess whether they meet their production needs.

Based on the specific needs of each customer, KINGREAL provides customized heavy duty purlin making machine manufacturing solutions to ensure that every customer finds the most suitable heavy duty purlin roll forming machine for their project requirements. Customers interested in our heavy duty purlin making machines are welcome to contact KINGREAL!