- Home

- >

- News

- >

- Industry news

- >

News

In the modern construction industry, steel framing machines, as an emerging building solution, are gradually replacing traditional brick-and-mortar structures. Steel frame villas not only improve construction efficiency but also better meet the needs of sustainable development. Among numerous options, choosing a suitable expert partner is crucial. This article will explore the characteristics and industry background of metal framing machines, and how to select a trustworthy partner.

In modern construction engineering, production efficiency and precision are key factors for project success. Ceiling channel making machines, as highly efficient production equipment, are widely used in the construction industry. However, a single machine cannot independently meet complex construction needs. Only by using ceiling channel making machines in conjunction with metal stamping machines can a complete steel structure be formed, improving the production efficiency and installation quality of partition wall and suspended ceiling projects. This article will detail how ceiling channel making machines and metal stamping machines can be effectively combined to form a complete steel structure solution.

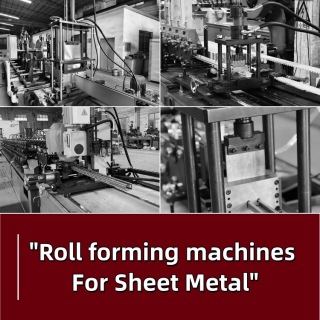

KINGREAL designs and manufactures a variety of roll forming machines widely used across multiple industries. These advanced roll forming machines meet the specific needs of customers in their projects. Besides, KINGREAL offers a variety of roll forming machine models designed to better serve the specific needs of customers and their industries. KINGREAL continuously improves the technology, production efficiency, performance, and durability of these roll forming machines to adapt to market changes and challenges. Contact KINGREAL today, our engineers will listen carefully to your production needs and recommend roll forming machine solutions that fit your budget and specifications.

Metal cut to length lines are precision coil processing equipment commonly used in the automotive industry, primarily for uncoiling, straightening, cutting, and stacking large metal coils used in automobile manufacturing. In the automotive industry, metal cut to length machines provide manufacturers with high-quality metal sheets that offer high surface quality, burr-free cuts, optimal flattening effects, and neat, standardized finished product stacks, ensuring no collisions or scratches. Because the precision sheets produced by metal cut to length lines undergo secondary processing, they can be used to manufacture important automotive components such as chassis, axles, suspension parts, doors and hoods, fuel tanks, interior parts, and body panels, thus enjoying widespread market demand.

A steel slitting machine is a widely used coil processing device in the metalworking industry, primarily used to cut wide coils into narrow strips. These strips can then be wound up for subsequent processes. Due to their high production speed and precise cutting capabilities, steel slitting lines are essential equipment in metalworking, transformer, motor industries, and other applications requiring precise shearing of metal strips.

Warehouse pallet rack machines, including ▶Shelf Panel Making Machine|Upright Rack Making Machine|Box Beam Making Machine|Step Beam Making Machine|Slotted Angle Rack Machine◀, provide flexible pallet racking solutions for various warehouse needs. These storage rack roll forming machines range from selective pallet racking to high-density racking systems, and even complex picking modules, meeting the requirements of different application scenarios. The profiles produced by these warehouse pallet rack machines not only have advantages in strength and durability but also ensure that the racking system is more robust and wear-resistant, reducing the need for frequent replacements. The following will detail the applications of storage rack roll forming machines and how to choose the right pallet racking system.

KINGREAL boasts a range of advanced roll forming machines specifically designed for producing galvanized steel profiles for gypsum board applications. This roll forming machine not only enhances production efficiency but also ensures high-quality finished products. Depending on the application, these profiles are typically categorized as ceiling profiles, wall profiles, and corner profiles.

Modern construction and industrial systems depend much on the HVAC sector. Many parts of HVAC systems depend on premium metal processing, notably those for heating and cooling. Cutting vast coils of metal (like as galvanized steel or aluminum) into thin strips for further manufacturing into the intended final items, metal slitting machines are vital tools. The several benefits metal slitting machines provide in the HVAC sector will be discussed in depth in this essay.

In the modern construction industry, the light steel frame machine has revolutionized traditional construction methods. Using galvanized steel as raw material, light gauge steel frame machine produces metal frames such as wall panels, floor trusses, and roof trusses through a cold-bending process, widely used in the construction of light steel structure houses.

KINGREAL drywall profile machines are specifically designed for producing galvanized steel profiles for drywall applications. This highly efficient stud and track machine ensures precise manufacturing of studs and tracks, providing an ideal production solution for companies requiring large-scale production, high efficiency, and high-quality finished products. With the increasing demand for drywall materials in the construction industry, KINGREAL drywall profile machines are becoming the preferred choice for many companies.

Sheet metal processing technology is always developing as demand for materials increases in industries including construction, automotive, aviation, and electronics. creative to satisfy ever more sophisticated market requirements. Particularly against the backdrop of growing intense worldwide rivalry, companies must quickly raise product quality and production efficiency to keep their competitive edge.

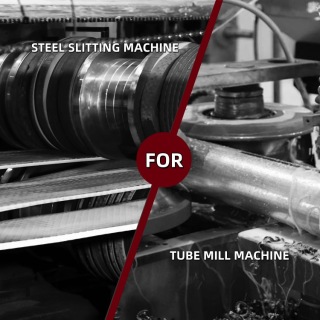

Steel slitting lines and tube mill machines are both essential equipment in modern industry. Their widespread demand in the steel processing sector leads to a close relationship between them. This article will provide a detailed introduction to the working principles, features, and collaborative relationship between steel slitting line and tube mill machine, helping you better understand their importance in industrial production.